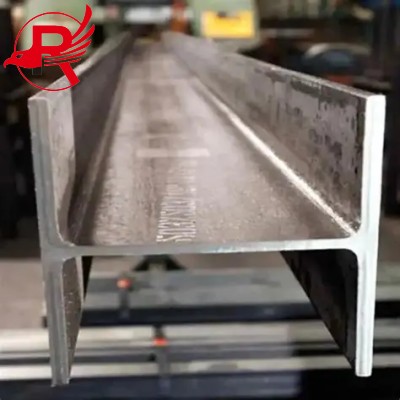

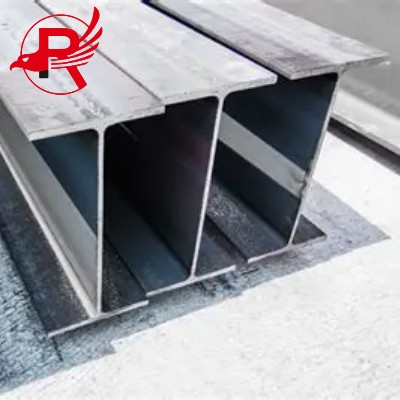

What is H Beam?

H-beams are economical, high-efficiency profiles with a cross-section similar to the letter "H." Their core features include optimized cross-sectional area distribution, a reasonable strength-to-weight ratio, and right-angled components. These components offer multi-directional bending resistance, ease of construction, lightweight construction (15%-30% lighter than traditional steel structures), and cost savings. Compared to conventional I-beams (I-beams), H-beams feature wider flanges, greater lateral stiffness, and approximately 5%-10% improved bending resistance. Their parallel flange design simplifies connection and installation. They are widely used in heavy-load applications such as large buildings (such as factories and high-rise buildings), bridges, ships, and foundations for lifting machinery and equipment, significantly improving structural stability and reducing material consumption.

Advantages of H-beam

1. Excellent Mechanical Properties

Strong Flexural Capacity: Wide and thick flanges (over 1.3 times wider than I-beams) provide a large cross-sectional moment of inertia, improving flexural performance by 10%-30%, making it particularly suitable for long-span structures.

Biaxial Compressive Stability: The flanges are perpendicular to the web, resulting in high lateral stiffness and superior torsional and roll resistance to I-beams.

Uniform Stress Distribution: Smooth cross-sectional transitions reduce stress concentration and extend fatigue life.

2. Lightweight and Economical

High Strength-to-Weight Ratio: 15%-30% lighter than traditional I-beams at the same load-bearing capacity, reducing the weight of the structure.

Material Savings: Reduced concrete foundation usage reduces overall construction costs by 10%-20%.

Low Transportation and Installation Costs: Standardized components reduce on-site cutting and welding.

3. Convenient and Efficient Construction

Parallel flange surfaces facilitate direct connection to other components (steel plates, bolts), increasing construction speed by 20%-40%.

Simplified Joints: Reduce complex joints, strengthen the structure, and shorten construction time.

Standardized Specifications: Globally accepted standards such as the Chinese National Standard (GB/T 11263), the Japanese Standard (JIS), and the American Standard (ASTM A6) ensure easy procurement and adaptability.

4. Wide Range of Applications

Heavy Construction: Factories, high-rise steel structures (such as the core of the Shanghai Tower), and large venues (such as the Bird's Nest truss support).

Bridges and Transportation: Railway bridges and highway viaducts (with long-span box girder supports).

Industrial Equipment: Heavy machinery chassis and port crane track beams.

Energy Infrastructure: Power plant piers and oil platform modules.

5. Environmental Sustainability

100% Recyclable: High steel recycling rates reduce construction waste.

Reduced Concrete Use: Reduces carbon emissions (each ton of steel replaced with concrete saves 1.2 tons of CO₂).

Applications of H Beam

Most common uses of H Beams factory are for platforms, bridges, ship and dock building. While I Beams are commonly used for typical commercial buildings or any other lighthweight applications.

From super-high-rise landmarks to public infrastructure, from heavy industry to green energy, H-beams have become an irreplaceable structural material for modern engineering. When selecting China H beam companies, specifications must be matched based on load, span, and corrosion environment (for example, coastal projects require weathering steel Q355NH) to maximize their safety and economic value.

China Royal Corporation Ltd

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506

Post time: Aug-07-2025