In today's steel construction, selecting the appropriate structural element is essential to achieve economy, stability, and durability. Within the major steel profiles, C Channel and U Channel are instrumental in building and many other industrial applications. At first glance they look alike but the properties and application are quite different.

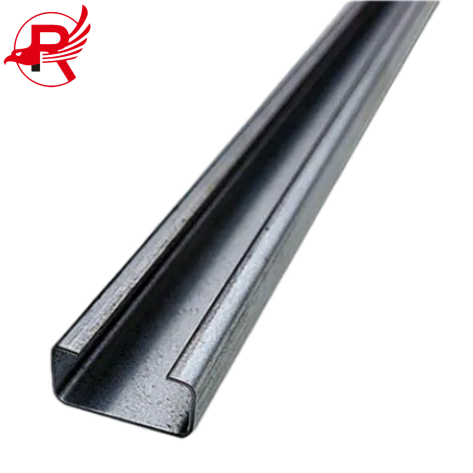

C Channel

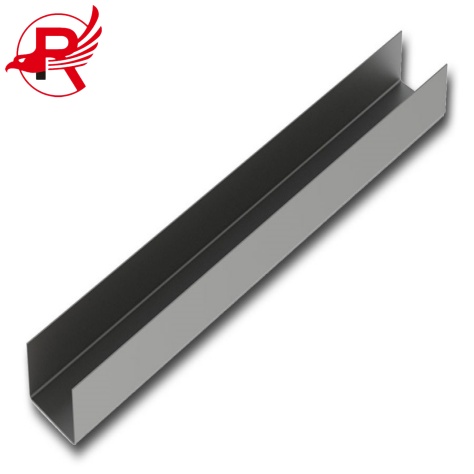

U Channel

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506

Post time: Nov-27-2025