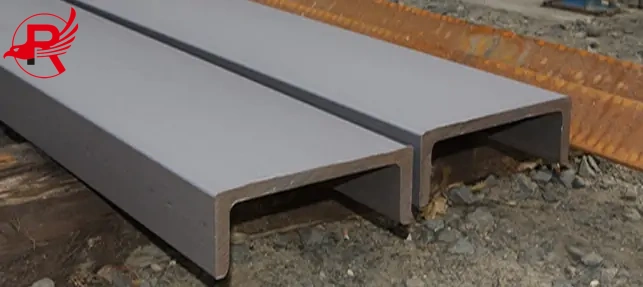

In the global steel industry, C Channel and U Channel play essential roles in construction, manufacturing, and infrastructure projects. While both serve as structural supports, their design and performance characteristics differ significantly — making the choice between them crucial depending on project requirements.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506

Post time: Oct-20-2025