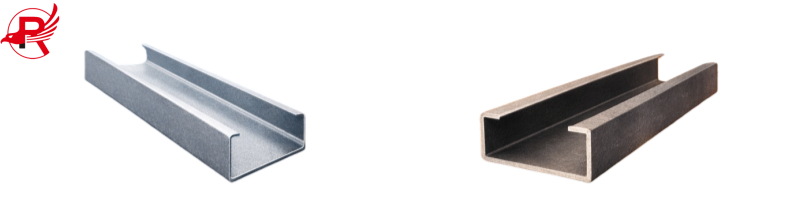

With the global infrastructure market set to be completely dominated by "lightweighting" and "low-carbonization" in 2026, architects and procurement managers are yet again confronted with a critical decision in steel structure projects: C-purlins or C-channels?

Despite their similar appearances, the process, mechanical properties, and application scenarios of these two directly influence the safety and economy of the project. Here is a comparison of the fundamental technologies the construction sector will need to master in 2026.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506

Post time: Jan-13-2026