Clarify Purpose and Requirements

When selecting U-channel steel, the first task is to clarify its specific use and core requirements:

This includes accurately calculating or evaluating the maximum load it needs to withstand (static load, dynamic load, impact, etc.), which directly determines the specifications and dimensions (height, leg width, waist thickness) and material strength grade; understanding its application scenarios (such as building structure beams/purlins, mechanical frames, conveyor line supports, shelves or decorations), different scenarios have different emphases on strength, rigidity, precision and appearance; considering the use environment (indoor/outdoor, whether it is humid, corrosive media), which determines the anti-corrosion requirements (such as hot-dip galvanizing, painting) or whether weathering steel/stainless steel is required; clarifying the connection method (welding or bolting), which will affect the leg design (flat welding surface or reserved holes are required) and the requirements for material weldability; at the same time, it is necessary to confirm the size restrictions of the installation space (length, height, width) and the specific regulations or industry standards that the project must comply with to ensure that the selected materials meet all safety and functional requirements.

U Channel Steel Specifications, Dimensions and Materials

1. Specifications

European standard UPN channel models are named after their waist height (unit: mm). They have a U-shaped cross-section and key parameters include:

Waist height (H): The overall height of the channel. For example, the waist height of UPN240 is 240 mm.

Band width (B): The width of the flange. For example, the UPN240 has an 85 mm band.

Waist thickness (d): The web thickness. For example, the UPN240 has a waist thickness of 9.5 mm.

Band thickness (t): The flange thickness. For example, the UPN240 has a band thickness of 13 mm.

Theoretical weight per meter: The weight per unit length (kg/m). For example, the UPN240 has a weight of 33.2 kg/m.

Common Specifications (Partial Models):

| model | Waist height (mm) | Leg width (mm) | Waist thickness (mm) | Leg thickness (mm) | Theoretical weight per meter (kg/m) |

| UPN80 | 80 | 45 | 6 | 8 | 8.64 |

| UPN100 | 100 | 50 | 6 | 8.5 | 10.6 |

| UPN120 | 120 | 55 | 7 | 9 | 13.4 |

| UPN200 | 200 | 75 | 8.5 | 11.5 | 25.3 |

| UPN240 | 240 | 85 | 9.5 | 13 | 33.2 |

| UPN300 | 300 | 100 | 10 | 16 | 46.2 |

| UPN350 | 350 | 100 | 14 | 16 | 60.5 |

2. Material type

UPN channel steel material must meet the European standard EN 10025-2. Common options include:

(1) Common materials

S235JR: Yield strength ≥ 235MPa, low cost, suitable for static structures (such as light supports).

S275JR: Yield strength ≥ 275MPa, balanced strength and economy, used for general building frames.

S355JR: Yield strength ≥ 355MPa, first choice for high load, suitable for high stress scenarios such as port machinery and bridge supports. Its tensile strength reaches 470~630MPa, and it has good low temperature toughness.

(2) Special materials

High strength steel: such as S420/S460, used for nuclear power equipment and ultra-heavy machinery bases (such as UPN350).

Weathering steel: such as S355J0W, resistant to atmospheric corrosion, suitable for outdoor bridges.

Stainless steel: used in corrosive environments such as chemical and marine, but with higher cost.

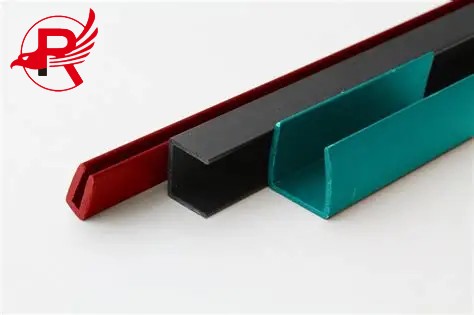

(3) Surface treatment

Hot-rolled black: default surface, requires subsequent anti-corrosion treatment.

Hot-dip galvanizing: galvanized layer ≥ 60μm (such as channel steel for pipe gallery supports), improves corrosion resistance.

3. Selection recommendations

High-load scenarios (such as port crane rails): Prioritize UPN300~UPN350 + S355JR materials to ensure bending and shear resistance.

Corrosive environment: Combine with hot-dip galvanizing or directly use weathering steel.

Lightweight requirements: UPN80~UPN120 series (meter weight 8.6~13.4kg/m), suitable for curtain wall keels and pipe supports.

Note: When purchasing, it is necessary to verify the material report (in accordance with EN 10025-2) and dimensional tolerance (EN 10060) to ensure project compliance.

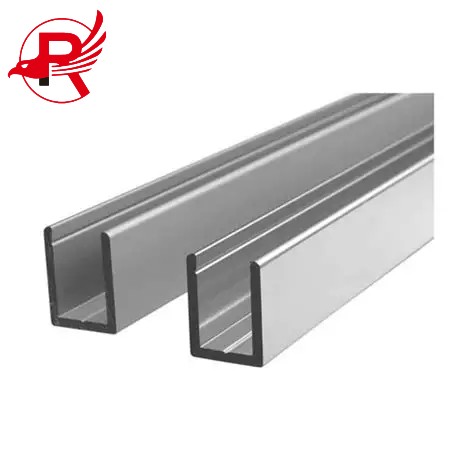

Reliable U Channel Manufacturer Recommendation-Royal Group

At Royal Group, we are a leading partner in Tianjin's industrial metal materials trading sector. With professionalism and a commitment to prioritizing quality, we have established ourselves not only in U-shaped steel, but also in all our other products.

Every product offered by Royal Group undergoes a rigorous quality inspection process to ensure it meets or exceeds the highest quality standards. This helps us provide our customers with reliable and safe products suitable for a variety of applications.

We understand that time is of the essence for our customers, and therefore, our staff and fleet of vehicles are always ready to deliver goods. By ensuring speed and punctuality, we help our customers save time and optimize their construction processes.

Royal Group not only brings confidence in product quality and value, but also demonstrates sincerity in our customer relationships. We offer not only a variety of U-shaped steel, but also a wide range of other products, such as H-shaped steel, I-shaped steel, and C-shaped steel, to meet the diverse needs of customers nationwide.

Every order placed with Royal Group is inspected before payment. Customers have the right to inspect their products before payment to ensure satisfaction and product quality.a

China Royal Steel Ltd

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506

Post time: Aug-11-2025