Current Status of H-shaped Steel Development

In the ever-evolving landscape of bridge engineering, a groundbreaking shift is underway with the innovative application of H-beam profiles. Engineers and construction teams across the industry are now leveraging the unique properties of H-beam profiles, paired with advanced lightweight design, to significantly enhance the structural load-bearing capacity of bridges—marking a new era of efficiency, safety, and sustainability in infrastructure development.

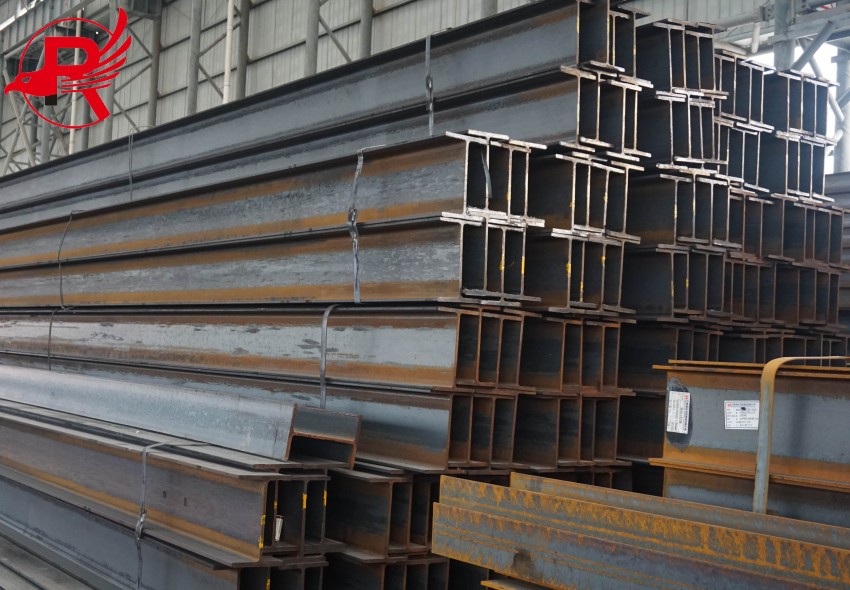

Introduction and advantages of H-shaped steel

H-beam profiles, known for their distinct "H" shaped cross-section, have long been recognized for their superior mechanical performance. Unlike traditional steel profiles such as I-beams, H-beams feature parallel upper and lower flanges connected by a thick web, resulting in a more balanced distribution of strength. This structural advantage allows H-beams to resist bending and torsion more effectively, making them an ideal choice for load-bearing components in bridge projects. However, it is the integration of lightweight design principles that has unlocked their full potential in recent years.

“For decades, bridge engineers faced a trade-off: to boost load-bearing capacity, we often had to increase the weight and volume of steel used, which raised construction costs, extended project timelines, and added pressure to foundation structures,” explained Dr. Elena Carter, a senior structural engineer at Global Infrastructure Innovations (GII), a leading firm in bridge design and construction. “With H-beam profiles and lightweight design, we’ve shattered that trade-off. By optimizing the cross-sectional dimensions of H-beams—reducing unnecessary material in non-critical areas while reinforcing high-stress zones—we’ve created structures that are lighter yet far more capable of handling heavy loads.”

What are the benefits of lightweight design of H-shaped steel?

“The lightweight design of H-beams didn’t just improve load capacity; it transformed the entire construction process,” said Mark Torres, project manager for the West River Crossing Bridge. “Lighter components meant we could use smaller cranes, reduce the number of transportation trips for materials, and speed up on-site assembly. The project was completed three weeks ahead of schedule, and we saved approximately $1.5 million in construction costs. For local communities, this means earlier access to a safer, more reliable transportation route.”

Beyond cost and efficiency gains, the innovative use of H-beam profiles in bridge engineering also contributes to sustainability goals. By reducing steel consumption, projects like the West River Crossing Bridge lower carbon emissions associated with steel production— a key factor in global efforts to mitigate climate change. Additionally, the lightweight design reduces the environmental impact of bridge foundations, as less excavation and concrete are needed to support the structure, minimizing disruption to local ecosystems.

The future development of H-shaped steel

Industry experts predict that this trend will continue to gain momentum as infrastructure projects worldwide prioritize resilience and sustainability. The International Association of Bridge and Structural Engineers (IABSE) recently released a report noting that H-beam profiles with lightweight design are expected to be used in 45% of medium-to-large bridge projects by 2028, up from just 15% in 2020.

“Bridges are the backbone of transportation networks, and their performance directly impacts economies and daily life,” Dr. Carter added. “The innovative application of H-beam profiles is not just a technical advancement—it’s a solution that addresses the industry’s most pressing challenges: safety, efficiency, and sustainability. As we continue to refine lightweight design techniques and develop even higher-strength H-beam materials, we’ll be able to build bridges that are smarter, more durable, and better suited to meet the needs of future generations.”

China Royal Steel Ltd

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506

Post time: Sep-02-2025