What is H Beam?

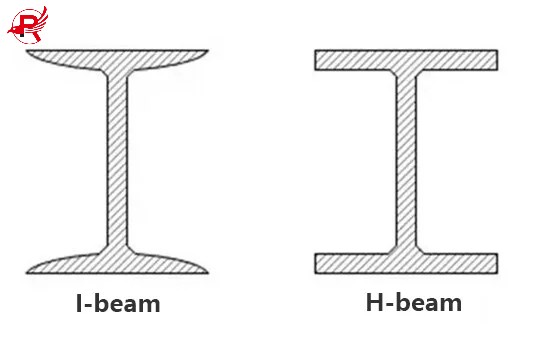

H-beam is an economical H-shaped steel profile, consisting of a web (the center vertical plate) and flanges (the two transverse plates). Its name stems from its resemblance to the letter "H." It is a highly efficient and economical steel material. Compared to ordinary I-beams, it boasts a larger section modulus, lighter weight, higher strength, and better mechanical properties. It is widely used in construction, bridge construction, and machinery manufacturing.

Advantages of H-shaped Steel Compared with Other Steel

| Comparison Aspect | H-Beam | Other Steel Sections (e.g., I-beam, channel steel, angle steel) |

| Cross-Section Design | H-shaped with parallel flanges and a thin web; uniform material distribution. | I-beam has tapered flanges; channel/angle steel has irregular, asymmetric sections. |

| Load-Bearing Capacity | 10-20% higher longitudinal strength and better lateral bending resistance due to wider flanges. | Lower overall load capacity; prone to stress concentration in specific areas. |

| Weight Efficiency | 8-15% lighter than equivalent traditional sections under the same load. | Heavier, increasing structural dead weight and foundation load. |

| Construction Efficiency | Minimal on-site processing; direct welding/bolting reduces work by 30-60%. | Requires frequent cutting/splicing; higher welding workload and defect risk. |

| Durability & Maintenance | Enhanced corrosion/fatigue resistance; maintenance cycles extended to 15+ years. | Shorter maintenance cycles (8-10 years); higher long-term upkeep costs. |

| Versatility | Available in rolled (standard) or welded (custom) forms for bridges, buildings, etc. | Limited adaptability to large-span or heavy-load projects. |

Application of H-shaped steel in daily life

Support structures for shopping malls and supermarkets: The high ceilings and load-bearing frames of multi-story floors in large shopping malls are often constructed using H-beams.

Roofs and stands for stadiums and theaters: For example, the stands of a residential complex, which can accommodate thousands of people, and the wide-span roof that covers the entire venue, rely on the lightweight and load-bearing capacity of H-beams.

Roof supports for vegetable markets and farmers' markets: The metal scaffolding at the tops of some open-air or semi-open-air vegetable markets often uses H-beams as the main beams.

Overpasses and underpasses: The overpasses we use every day often have H-beams as the load-bearing beams beneath the bridge deck.

Multi-story frames for parking lots: In multi-story parking lots in residential communities or shopping malls, the floor slabs and columns on each floor need to support the weight of vehicles, where the high strength and bending resistance of H-beams come in handy.

Pavilions and corridors in residential communities: Many residential communities have pavilions or corridors in their recreational areas, and the frames of these facilities are often made of H-beams (especially those that have been treated with anti-corrosion treatment).

Waste transfer station frames: Urban waste transfer stations require a sturdy structure to support the roof and equipment. H-beam steel's corrosion resistance (for some models) and load-bearing capacity are suitable for this environment, ensuring stable operation of the transfer station.

Charging station brackets: H-beam steel is often used as the base support frame for electric vehicle charging stations located on roadsides or in residential areas. It stabilizes the charging station while protecting it from vehicle collisions and inclement weather, providing peace of mind while charging.

Development trend of H-shaped steel

As the production process matures, the production capacity of the new H beam is expected to double within the next six months, making its market price even more competitive. Industry insiders predict that this high-performance steel will become the mainstream choice for large-scale domestic infrastructure projects within the next three to five years, providing a solid material foundation for the high-quality development of my country's infrastructure construction.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506

Post time: Aug-27-2025