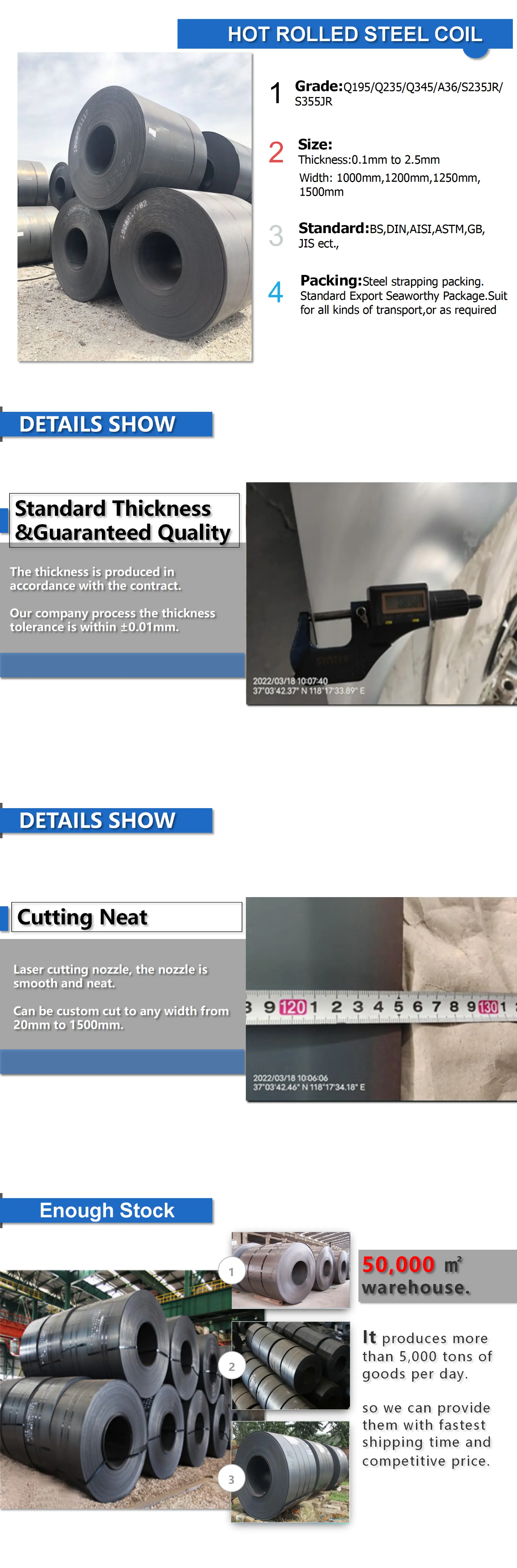

Building Material 5-20mm Hot Rolled Steel Sheet in Coil Shipbuilding Carbon Steel Plate Sheet Coil

Product Detail

|

Product Name |

Hotselling Best Quality A Large Amount Hot Rolled Steel Coil |

|

Material |

Q195/Q235/Q345/A36/S235JR/S355JR |

|

Thickness |

1.5mm~24mm |

|

Size |

3x1219mm 3.5x1500mm 4x1600mm 4.5x2438mm customized |

|

Standard |

ASTM A53-2007, ASTM A671-2006, ASTM A252-1998, ASTM A450-1996, ASME B36.10M-2004, ASTM A523-1996, BS 1387, BS EN10296, BS |

| 6323, BS 6363, BS EN10219, GB/T 3091-2001, GB/T 13793-1992, GB/T9711 | |

|

Grade |

A53-A369, Q195-Q345, ST35-ST52 |

| Grade A, Grade B, Grade C | |

|

Technique |

Hot rolled |

|

Packing |

Bundle, or with all kinds of colors PVC or as your requirements |

|

Pipe Ends |

Plain end/Beveled,protected by plastic caps on both ends, cut quare,grooved,threaded and coupling,etc. |

|

MOQ |

1 Tons, more quantity price will be lower |

|

Surface Treatment |

1. Mill finished /Galvanized /stainless steel |

| 2. PVC,Black and color painting | |

| 3. Transparent oil,anti-rust oil | |

| 4. According to clients requirement | |

|

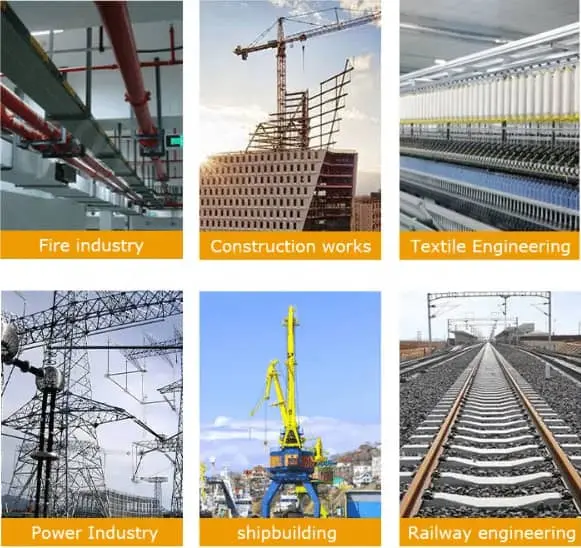

Product Application |

1. Manufacturing of building structures, |

| 2. lifting machinery, | |

| 3. engineering, | |

| 4. agricultural and construction machinery, | |

|

Origin |

Tianjin China |

|

Certificates |

ISO9001-2008,SGS.BV,TUV |

|

Delivery Time |

Usually within 10-15 days after receipt of advance payment |

Main Application

-

Fluid and gas delivery, steel structures, and construction applications.

-

ROYAL STEEL GROUP ERW/Welded round carbon steel pipes offer top-quality performance and reliable supply, making them ideal for steel structures and construction projects.

Note:

1.Free sampling, 100% after-sales quality assurance, support any payment term;

2.All other specifications of round carbon steel pipe are available as per your requirement (OEM&ODM)! You will get factory price from ROYAL STEEL GROUP.

Size Chart

| Thickness(mm) | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | customized |

| Width(mm) | 800 | 900 | 950 | 1000 | 1219 | 1000 | customized |

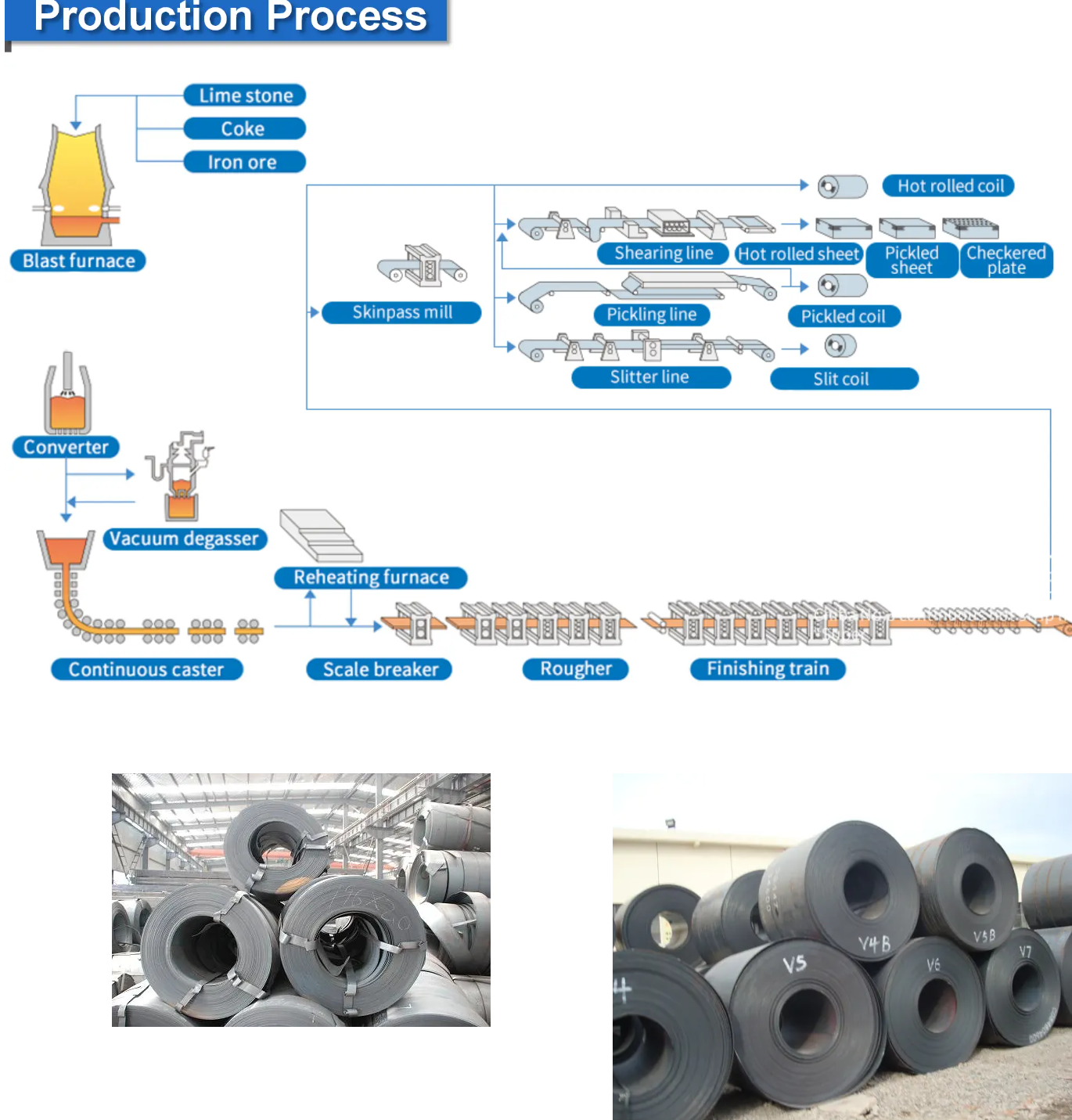

Process of production

Billet Processing: The raw material is a continuously cast ingot or bloom. The ingots are heated to a plastically deformable temperature in the range of 1100-1250°C in a furnace after the inspection, and when the ingots reaches the temperature for plastic deformation.

Roughing: The radiant-heated ingots are rolled in the roughing mill with a series of passes (normally 3-7) to bring the thickness down from 150-300 mm to 20-50 mm. The width is also reduced to produce a medium bar.

Finishing: Following dephosphorization (to remove surface oxide scale), the intermediate bar is introduced into the finishing mill for additional high-temperature rolling (around 5-7 passes), reducing the thickness further to 1.2-25.4 mm (based on the product specification). The rolling temperature and speed are regulated to attain the desired grain refinement and mechanical properties.

Coiling: Upon completion of finishing rolling, the strip is coiled at high speed to the predetermined temperature (generally between 500 and 700°C) using a laminar cooling system. The strip is then coiled by the coiler, then the hot rolled coil forming process is complete.

Testing Processing: The completed coils are subjected to dimension check, mechanical properties testing, and surface quality check. Upon qualification they are bundled, labeled and finally stored or shipped.

Packing and Transportation

Usually bare package

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

FAQ

Q: Are u a manufacturer?

A: Yes, we are the spiral steel tube manufacturer in Tianjin city, China.

Q: Can I have a trial order only several tons?

A: Of course. We can send the goods to you with LCL service (Less container load).

Q: If sample free?

A: Free sample, but freight cost is on buyer's side.

Q: Are you gold supplier and do trade assurance?

A: We•7 years gold supplier and accept trade assurance.