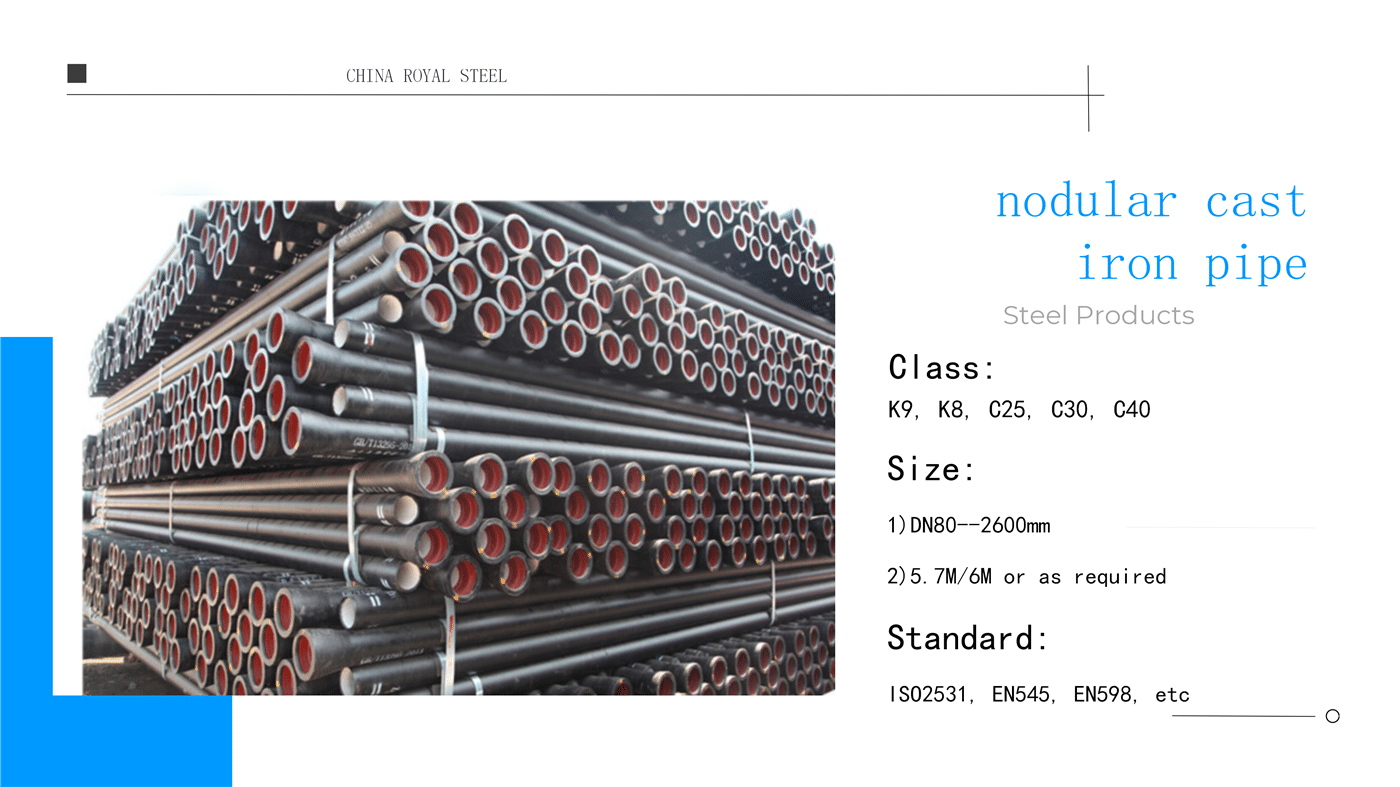

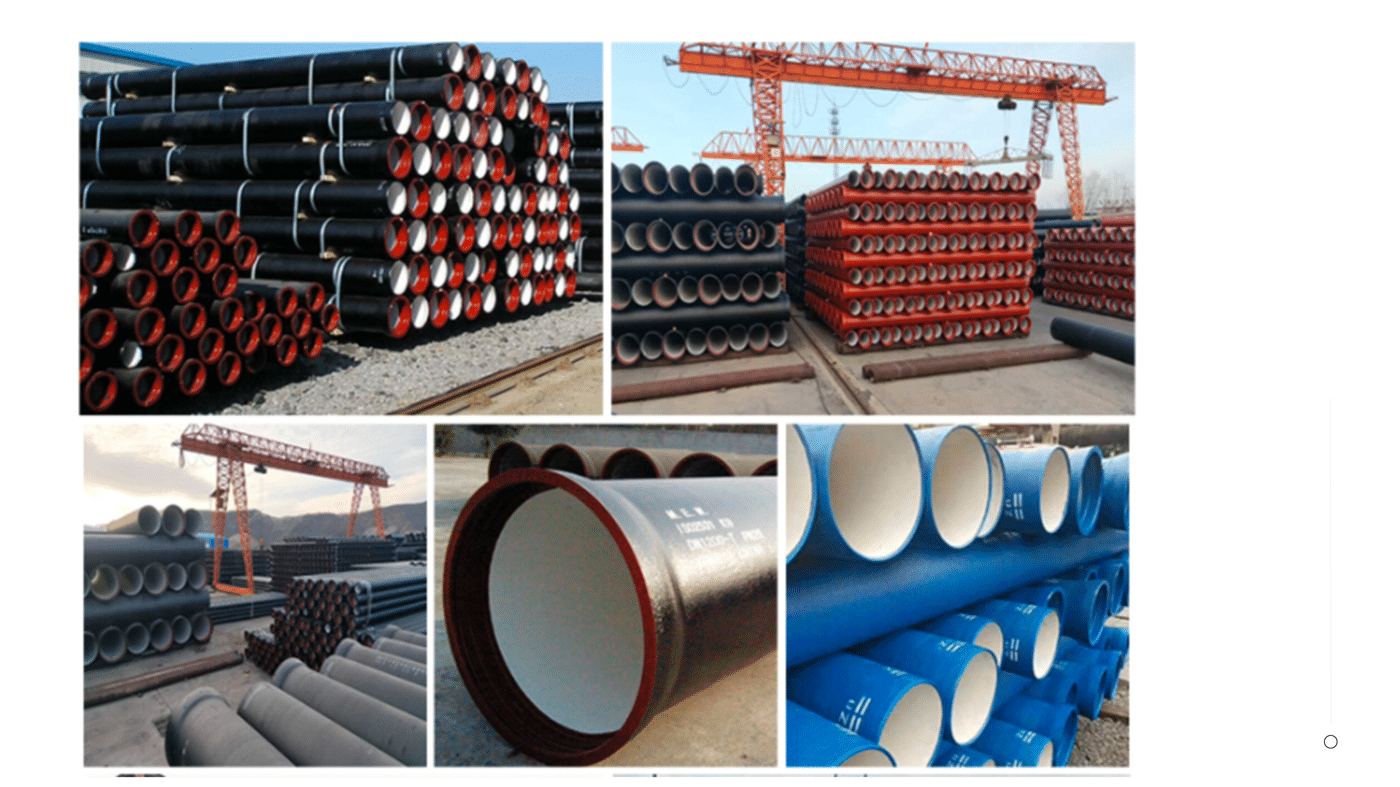

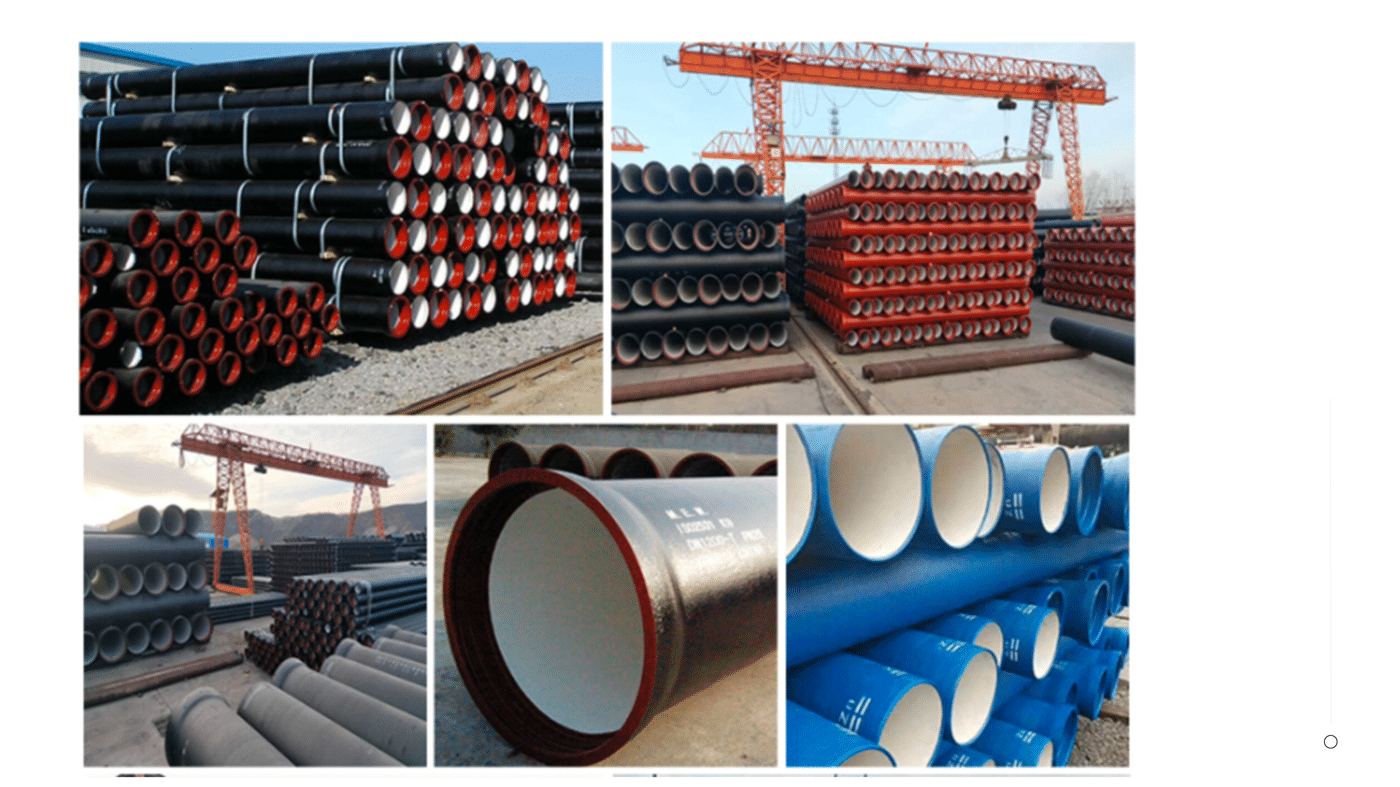

Factory Best Price 500mm K9 C40 6 Meter Long DI Pipe Ductile Iron Pipe for Water Supply

Product Detail

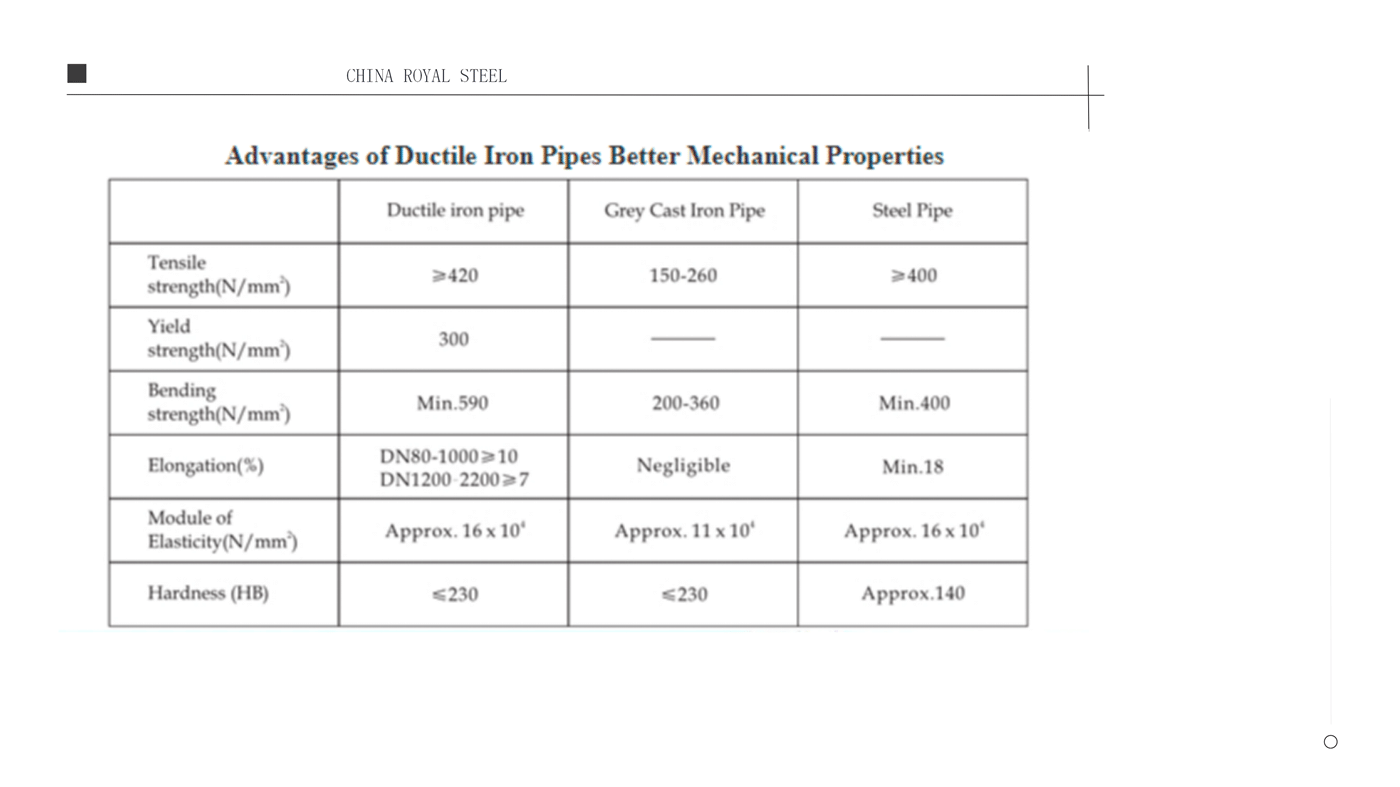

Nodular cast iron (or ductile iron) pipes offers the strength of steel and the toughness of iron. Graphite is spheroidized (grades 6–7) with a spheroidization degree of 1–3 and rate ≥80% and as a consequence the mechanical properties are improved. The microstructure after annealing is mainly ferrite with a small amount of pearlite, which has good ductility and strength.

|

All specifications products can be customized according to customer requirements |

|

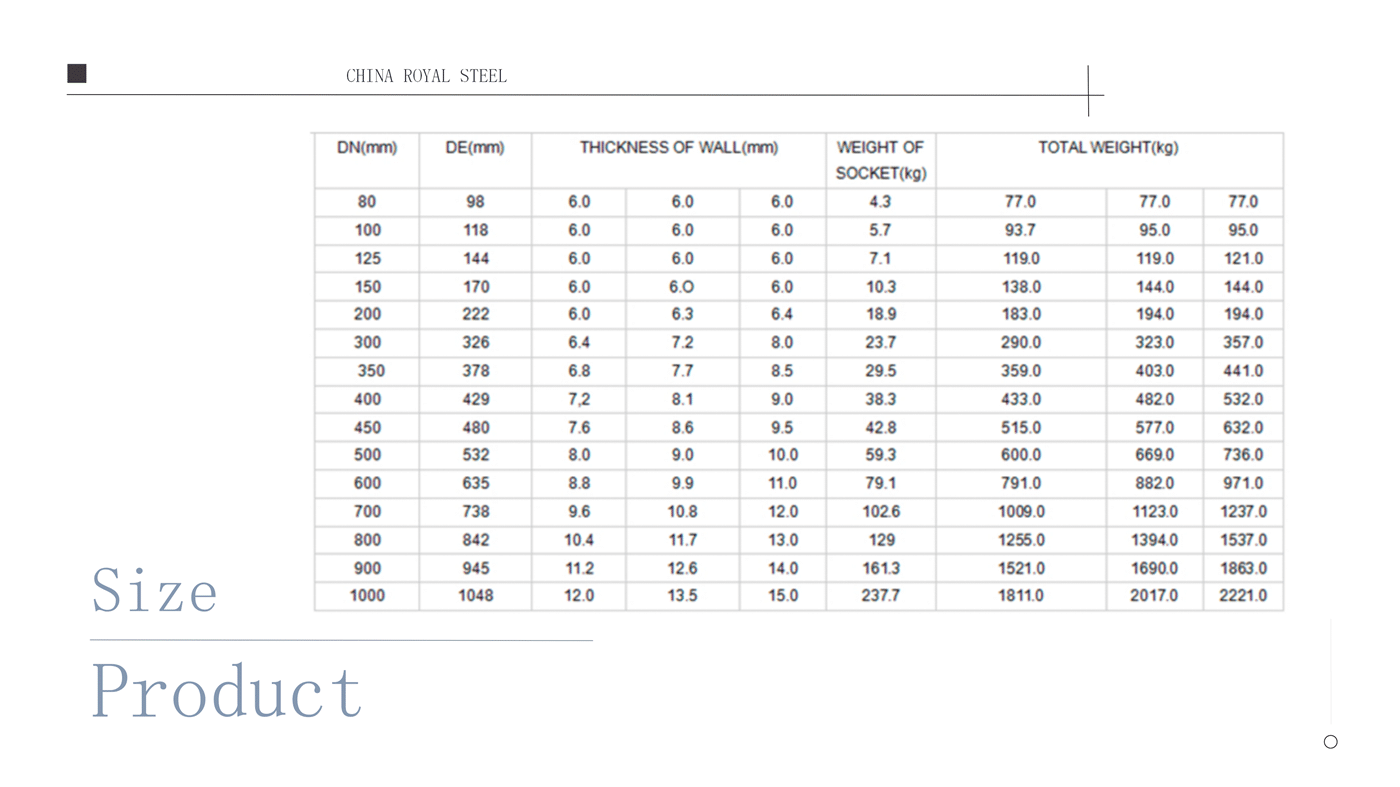

| 1. Size | 1)DN80~2600mm |

| 2)5.7M/6M or as required | |

| 2. Standard: | ISO2531, EN545, EN598, etc |

| 3.Material | Ductile Cast Iron GGG50 |

| 4. Location of our factory | Tianjin,China |

| 5. Usage: | 1)Urban water |

| 2) diversion pipes | |

| 3)agricultural | |

| 6.Internal Coating: | a). Portland cement mortar lining

b). Sulphate Resistant cement mortar lining c). High-Aluminum cement mortar lining d). Fusion bonded epoxy coating e). Liquid epoxy painting f). Black bitumen painting |

| 7.External Coating: | . zinc+bitumen(70microns) painting

. Fusion bonded epoxy coating c). Zinc-aluminum alloy+liquid epoxy painting |

| 8. Type: | Welded |

| 9. Processing Service | Welding, Bending, Punching, Decoiling, Cutting |

| 10. MOQ | 1 Ton |

| 11. Delivery: | Bundles, in bulk, |

1.Ductile Iron Pipes: The Difference is in the Manufacture, the Advantages in the Performance

2.Internal Pressure Resistance: High working pressure with a burst pressure of three times the working pressure, providing excellent safety.

3.Resistance to external pressure: The solid external resistance allows installation reliability and economic without using special bedding or encasement materials.

4.Inner Anti-Corrosion Layer: Centrifugal cement mortar lining (ISO 4179) provides a friction reduction and a long-lasting protection, making drinking water safe.

5.Protective Coating: Zinc spraying (≥130 g/m 2 , ISO 8179) combined with chlorinated resin paint offers better corrosion protection. Optional thicker zinc or zinc-aluminium coating are possible, according to the customer demand.

Features

Ductile Iron pipes are cast iron pipes which have been alloyed to include the strength of steel with the toughness of iron.

Spheroidization is regulated (rate ≥80%) in the levels 1–3 to improve the mechanical properties. Annealed pipes have a ferrite matrix with a small amount of pearlite and they provide very good resistance to corrosion, high plasticity, sealing and ease of use.

Microstructure Spherical Graphite There is a distribution of spherical graphite in the ferrite-pearlite matrix. The Pearlite content is different by size: for small pipes ≤20%, for large pipes ~25%. This enables them to be used for the safe and efficient transport of water, gas, and oil in urban and industrial applications.

Application

The ductile iron pipes with diameter ranging from 80 to 1600 mm are applicable to drinking water (BS EN 545) and sewage (BS EN 598) system. They are simple to connect, can be laid in any weather often without any special backfill and provide a high safety factor with flexibility for ground movement, making them the best choice for a wide variety of pipeline applications.

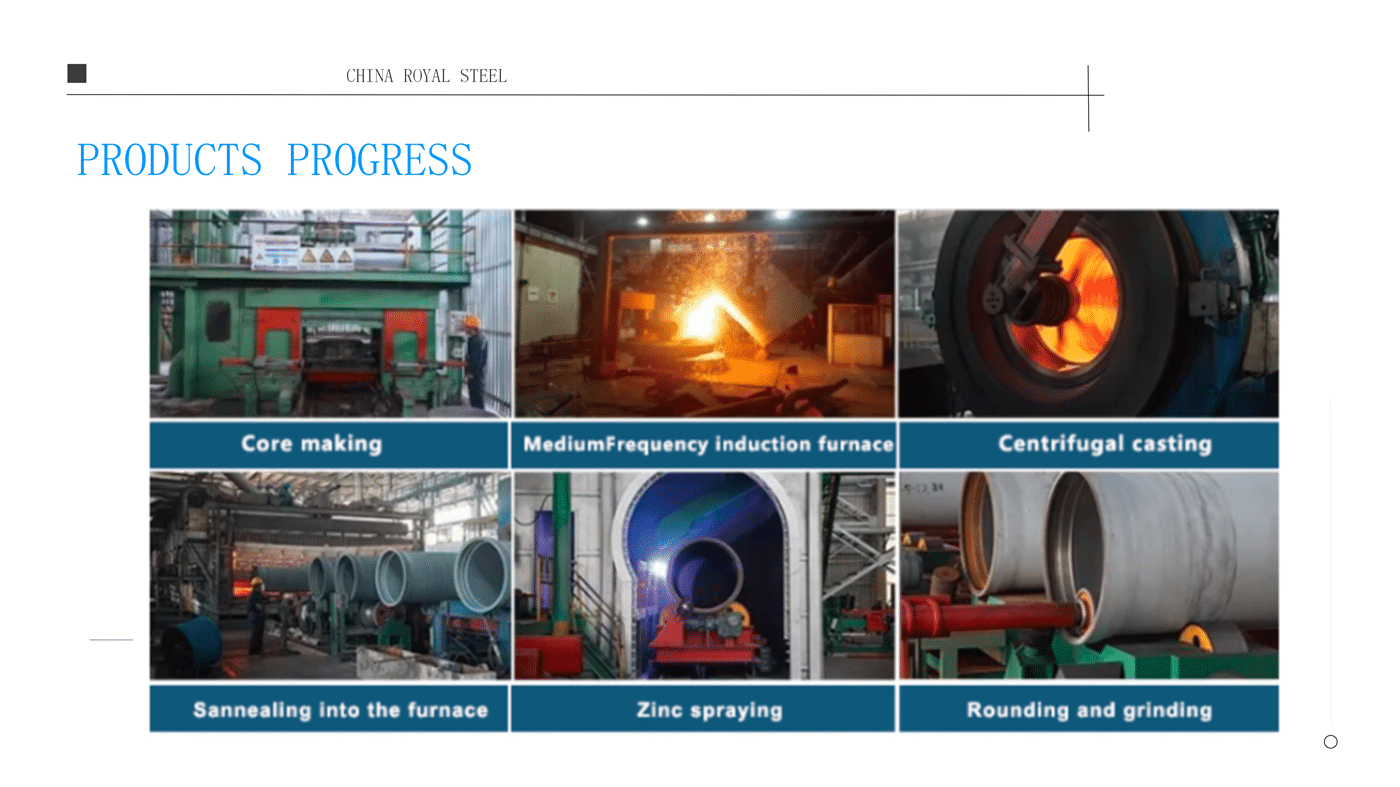

Production Process

Packaging & Shipping

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.