Factory Price 2024 Hot Sale C25 Grade Ductile Iron Pipe K8 K9 900mm Ductile Iron Pipe Cement Lined Pipe

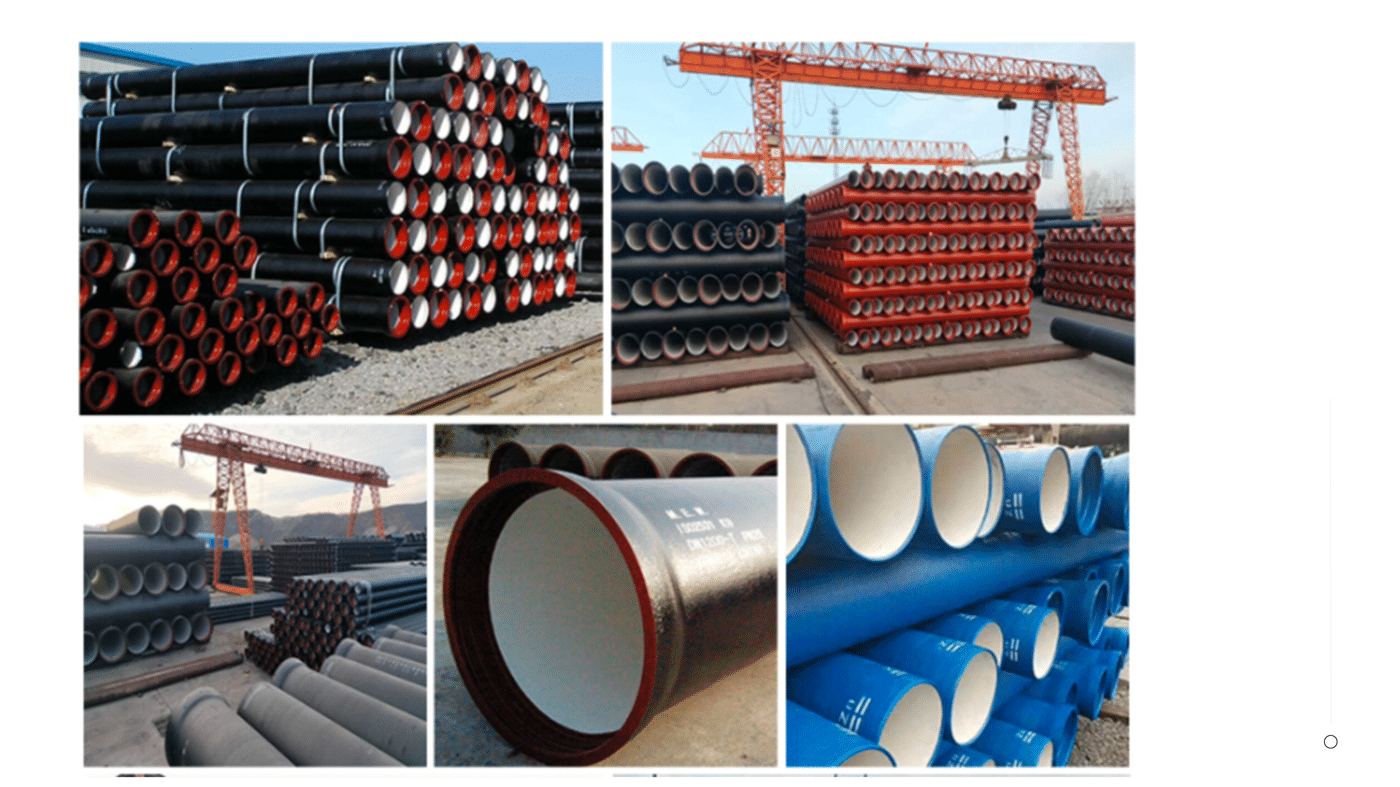

Product Detail

Nodular cast iron steel pipes are essentially ductile iron pipes, which have the essence of iron and the properties of steel, hence their name. Graphite in ductile iron pipes exists in a spherical form, with a general size of 6-7 grades. In terms of quality, the spheroidization level of cast iron pipes is required to be controlled at 1-3 levels, with a spheroidization rate of ≥ 80%. Therefore, the mechanical properties of the material itself have been improved, possessing the essence of iron and the properties of steel. After annealing, the microstructure of ductile iron pipes is ferrite with a small amount of pearlite, which has good mechanical properties, hence it is also called cast iron steel pipes.

|

All specifications products can be customized according to customer requirements |

|

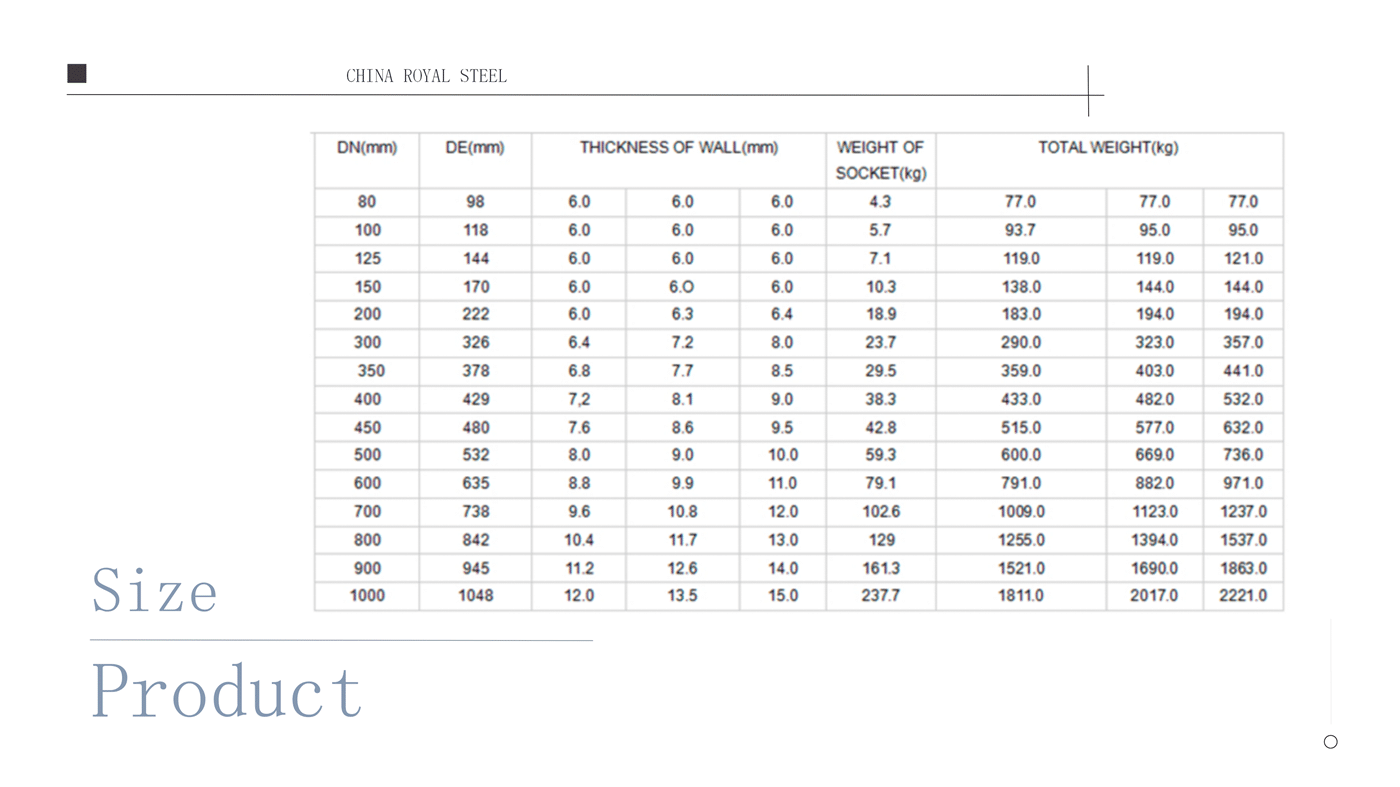

| 1. Size | 1)DN80~2600mm |

| 2)5.7M/6M or as required | |

| 2. Standard: | ISO2531, EN545, EN598, etc |

| 3.Material | Ductile Cast Iron GGG50 |

| 4. Location of our factory | Tianjin,China |

| 5. Usage: | 1)Urban water |

| 2) diversion pipes | |

| 3)agricultural | |

| 6.Internal Coating: | a). Portland cement mortar lining

b). Sulphate Resistant cement mortar lining c). High-Aluminum cement mortar lining d). Fusion bonded epoxy coating e). Liquid epoxy painting f). Black bitumen painting |

| 7.External Coating: | . zinc+bitumen(70microns) painting

. Fusion bonded epoxy coating c). Zinc-aluminum alloy+liquid epoxy painting |

| 8. Type: | Welded |

| 9. Processing Service | Welding, Bending, Punching, Decoiling, Cutting |

| 10. MOQ | 1 Ton |

| 11. Delivery: | Bundles, in bulk, |

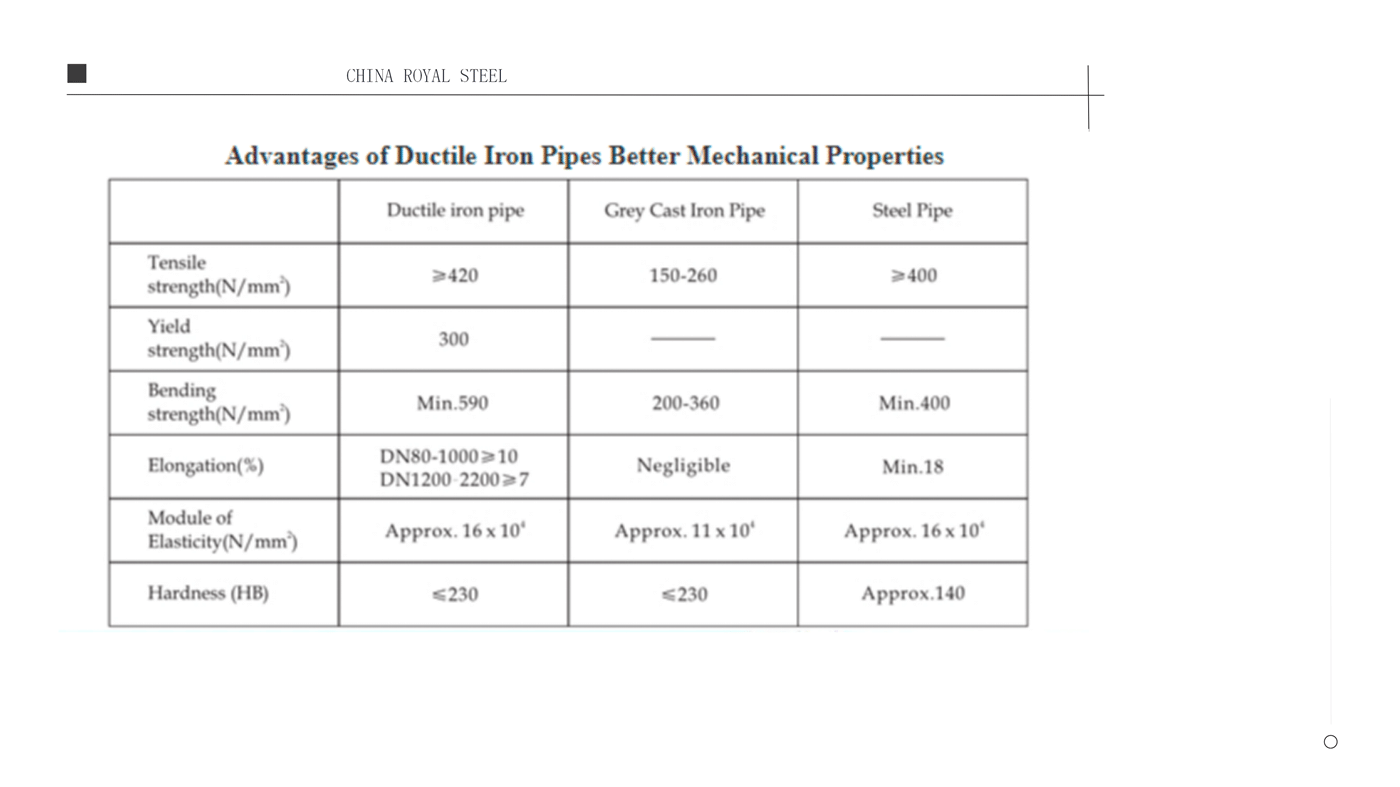

1.Internal Pressure Resistance: Ductile iron pipe has the strength of steel with the toughness of iron it is the safest choice. High working pressure is applied, and the burst pressure is up to three times of the working pressure.

2.External Pressure Resistance: Higher pressure resistance means less special bedding or sheeting is required, making your installation simpler and more economical.

3.Inner Anti-Corrosion Layer: Pipes are centrifugally lined with cement mortar in accordance with ISO 4179 for drinking water applications. This process produces a smooth, tough lining that protects the drinking water and doesn’t flake or rust.

4.Protective Layer: Zinc spraying (≥130 g/m², ISO 8179) and chlorinated Resin paint enable better protection against corrosion. Optional thicker zinc layers or zinc-aluminium coatings can be provided according to customers’ specifications.

Features

Ductile iron pipe is a type of cast iron pipe. Ductile iron pipes are manufactured at a level 1-3 of spheroidization(Spheroidizationrate>80%) to improve the mechanical propertiesby taking advantage of the strengthof steel and the toughness of iron. The annealed pipe has a ferrite structure with a small amount of pearlite, and has good corrosion resistance, ductility, sealing performance and easy for installation. They find extensive use in water supply, gas transmission, and oil transportation in city and industry.

Spherical graphite is surrounded by a matrix of ferrite and pearlite. The amount of pearlite to ferrite depends on the size of the pipe and its elongation requirements: for the most part, small-diameter pipes have pearlite ≤20% and large-diameter pipes ≈25%.

Application

Ductile iron pipes in sizes from 80 to 1600 mm are applicable in drinking water (BS EN 545) and in sewage (BS EN 598) systems. They joint easily, install in any weather, usually without special backfill, and provide a high factor of safety with enough flexibility to withstand ground movement, equipping them perfectly for use in a variety of pipeline applications.

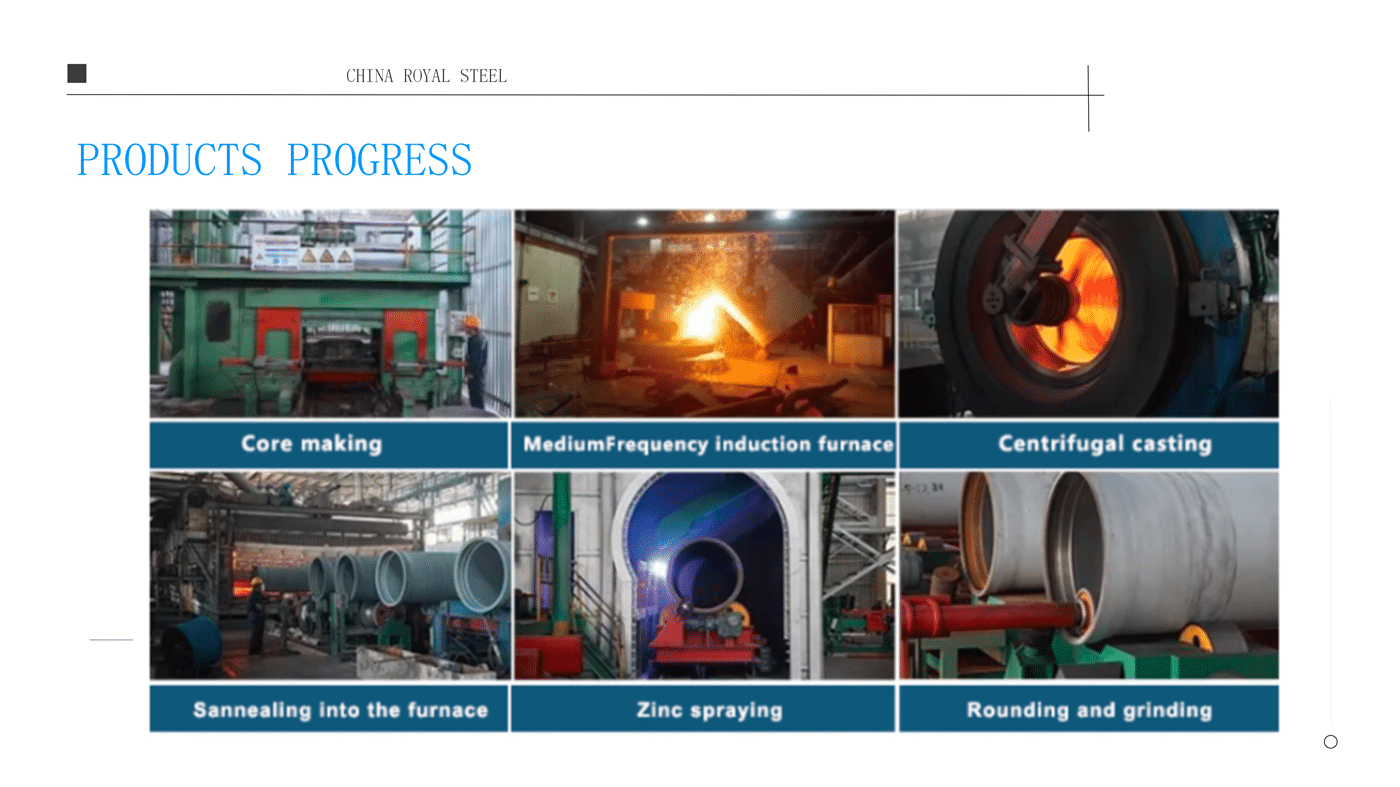

Production Process

Packaging & Shipping