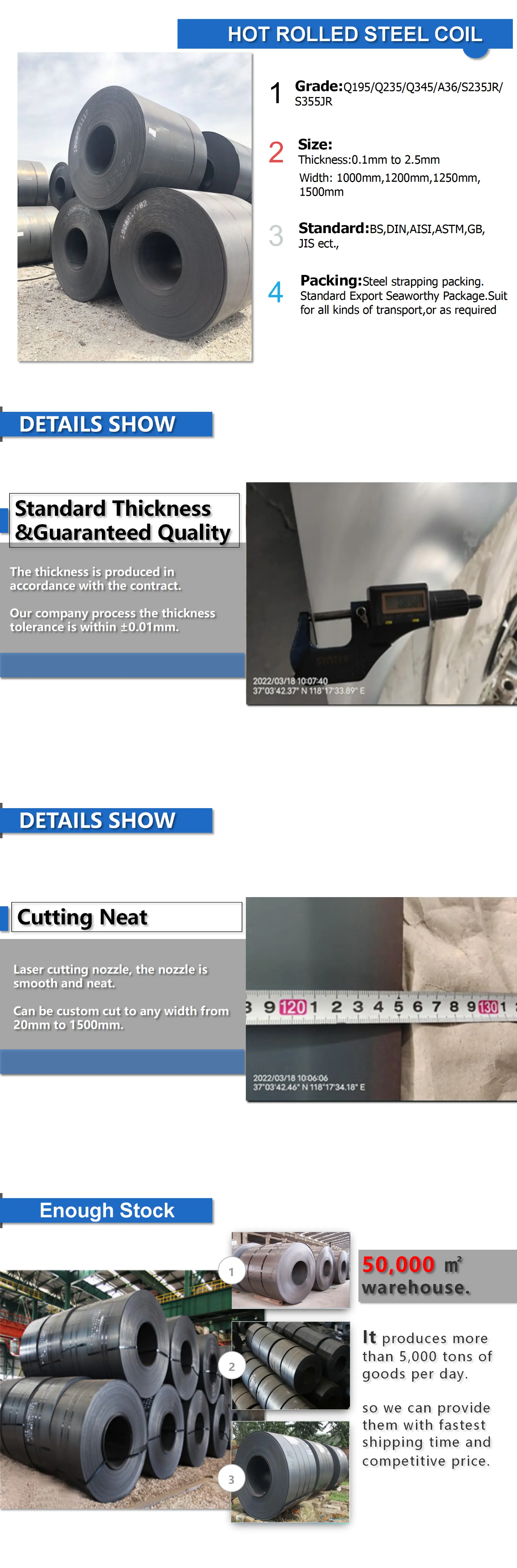

High Quality Hot-rolled Steel Coil Black Steel Coil S235 S355 SS400 Carbon Steel Coil

Product Detail

|

Product Name |

Hotselling Best Quality A Large Amount Hot Rolled Steel Coil |

|

Material |

Q195/Q235/Q345/A36/S235JR/S355JR |

|

Thickness |

1.5mm~24mm |

|

Size |

3x1219mm 3.5x1500mm 4x1600mm 4.5x2438mm customized |

|

Standard |

ASTM A53-2007, ASTM A671-2006, ASTM A252-1998, ASTM A450-1996, ASME B36.10M-2004, ASTM A523-1996, BS 1387, BS EN10296, BS |

| 6323, BS 6363, BS EN10219, GB/T 3091-2001, GB/T 13793-1992, GB/T9711 | |

|

Grade |

A53-A369, Q195-Q345, ST35-ST52 |

| Grade A, Grade B, Grade C | |

|

Technique |

Hot rolled |

|

Packing |

Bundle, or with all kinds of colors PVC or as your requirements |

|

Pipe Ends |

Plain end/Beveled,protected by plastic caps on both ends, cut quare,grooved,threaded and coupling,etc. |

|

MOQ |

1 Tons, more quantity price will be lower |

|

Surface Treatment |

1. Mill finished /Galvanized /stainless steel |

| 2. PVC,Black and color painting | |

| 3. Transparent oil,anti-rust oil | |

| 4. According to clients requirement | |

|

Product Application |

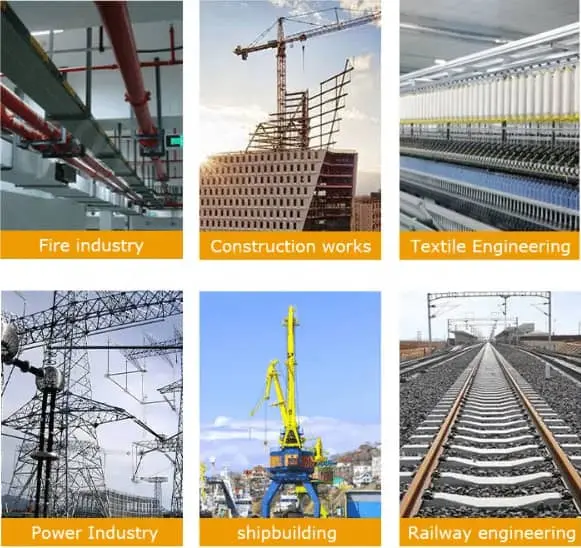

1. Manufacturing of building structures, |

| 2. lifting machinery, | |

| 3. engineering, | |

| 4. agricultural and construction machinery, | |

|

Origin |

Tianjin China |

|

Certificates |

ISO9001-2008,SGS.BV,TUV |

|

Delivery Time |

Usually within 10-15 days after receipt of advance payment |

Main Application

1.Fluid/Gas supply, Steel framework, Building;

2.ROYAL GROUP ERW/Welded round carbon steel pipes having top quality and powerful supply capacity are widely applied in Steel Structure and Construction.

Note:

1.Free sample,100%after services,Support any payment term;

2.All other specifications of round carbon steel pipe are available upon your request (OEM & ODM)! You will get the factory price from the ROYAL STEEL GROUP.

Size Chart

| Thickness(mm) | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | customized |

| Width(mm) | 800 | 900 | 950 | 1000 | 1219 | 1000 | customized |

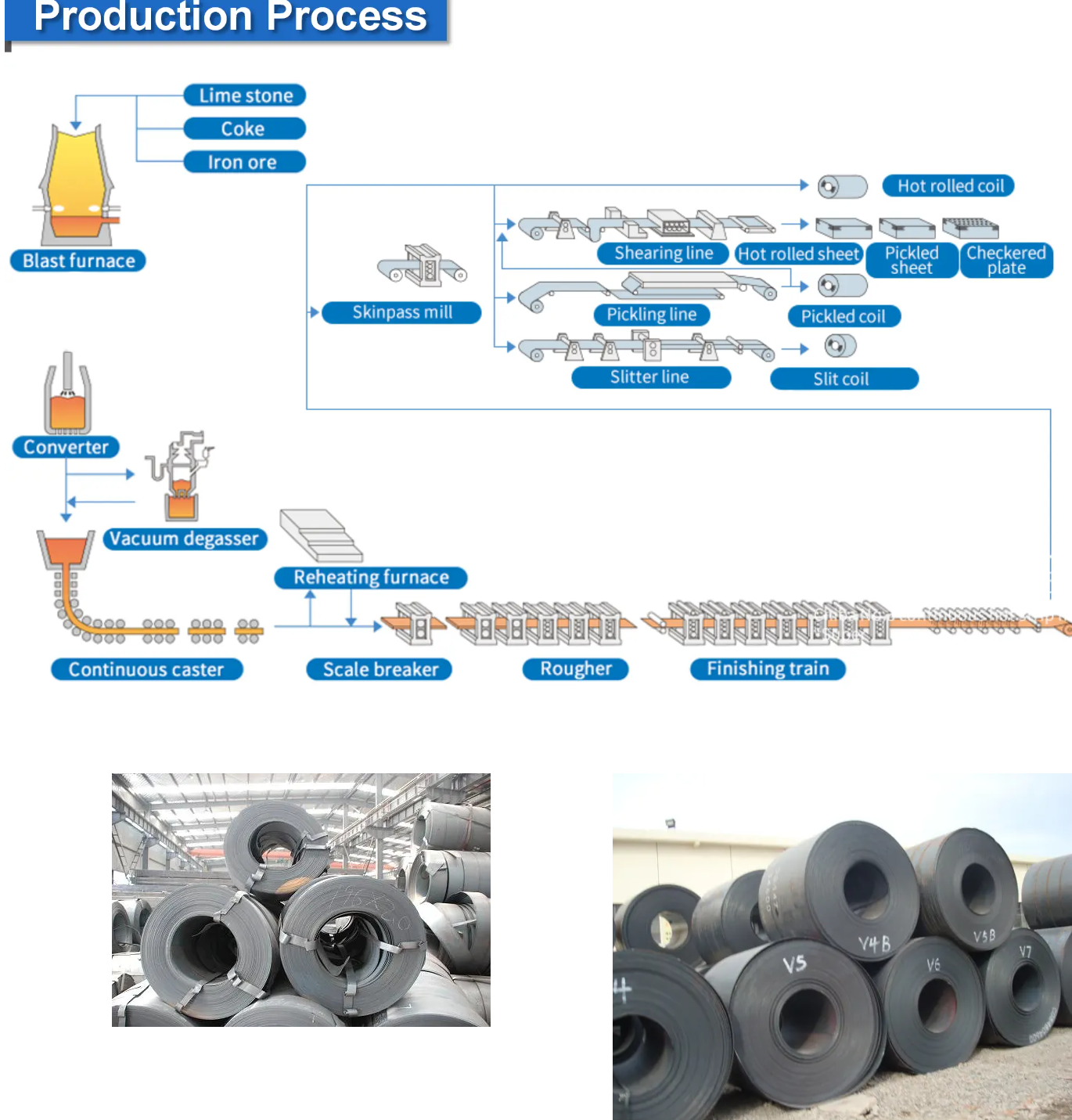

Process of production

Processing Billets: Solidified billets or blooms undergo inspection, surface imperfections are removed, and they are heated to 1100–1250°C for plastic working.

Roughing: Hot billets are rolled in the roughing mill (3–7passes), which reduces the thickness from 150–300 mm to 20–50 mm and also modifies the width the form intermediate billets.

Finishing: Following descaling, the semifinished billet is rolled in the finishing mill (5–7 passes) to the final thickness (1.2–25.4 mm), and the speed and temperature of the rolling are controlled to obtain a desired microstructure/grain and mechanical properties.

Coiling: After being air quenched (laminar cooling) at a high cooling rate (500–700°C), the hot-rolled strip is coiled.

Inspection & Processing: The finished coils are inspected for size, mechanical properties and surface quality and then baled, tagged and either stored or shipped out.

Packing and Transportation

Usually bare package

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

FAQ

Q: Are you a manufacturer?

A: Yes, we are a spiral steel tube manufacturer based in Tianjin, China.

Q: Can I place a small trial order?

A: Yes, we accept small orders and can ship via LCL (Less than Container Load).

Q: Are samples free?

A: Samples are free; the buyer only covers shipping costs.

Q: Are you a verified supplier and do you accept Trade Assurance?

A: Yes, we are a 7-year Gold Supplier and support Trade Assurance.