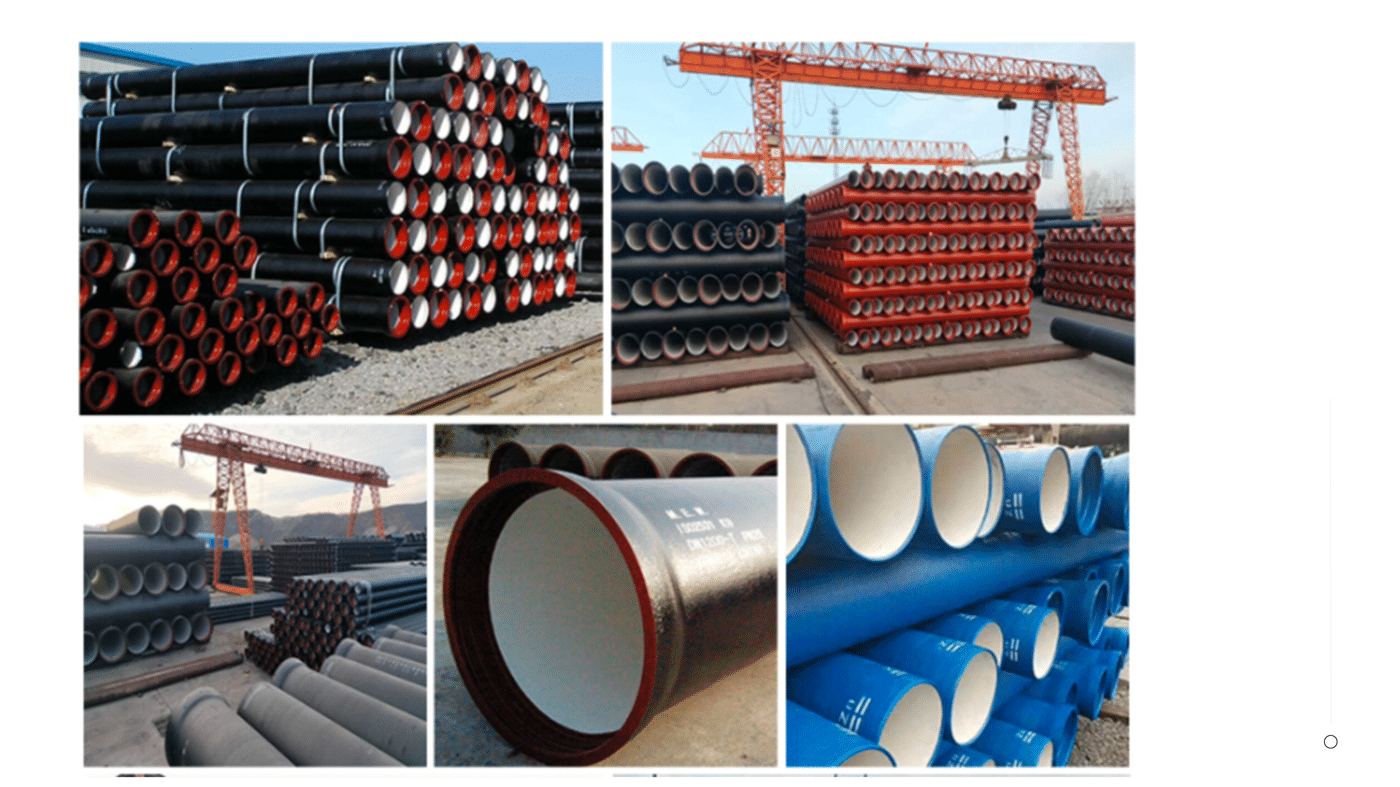

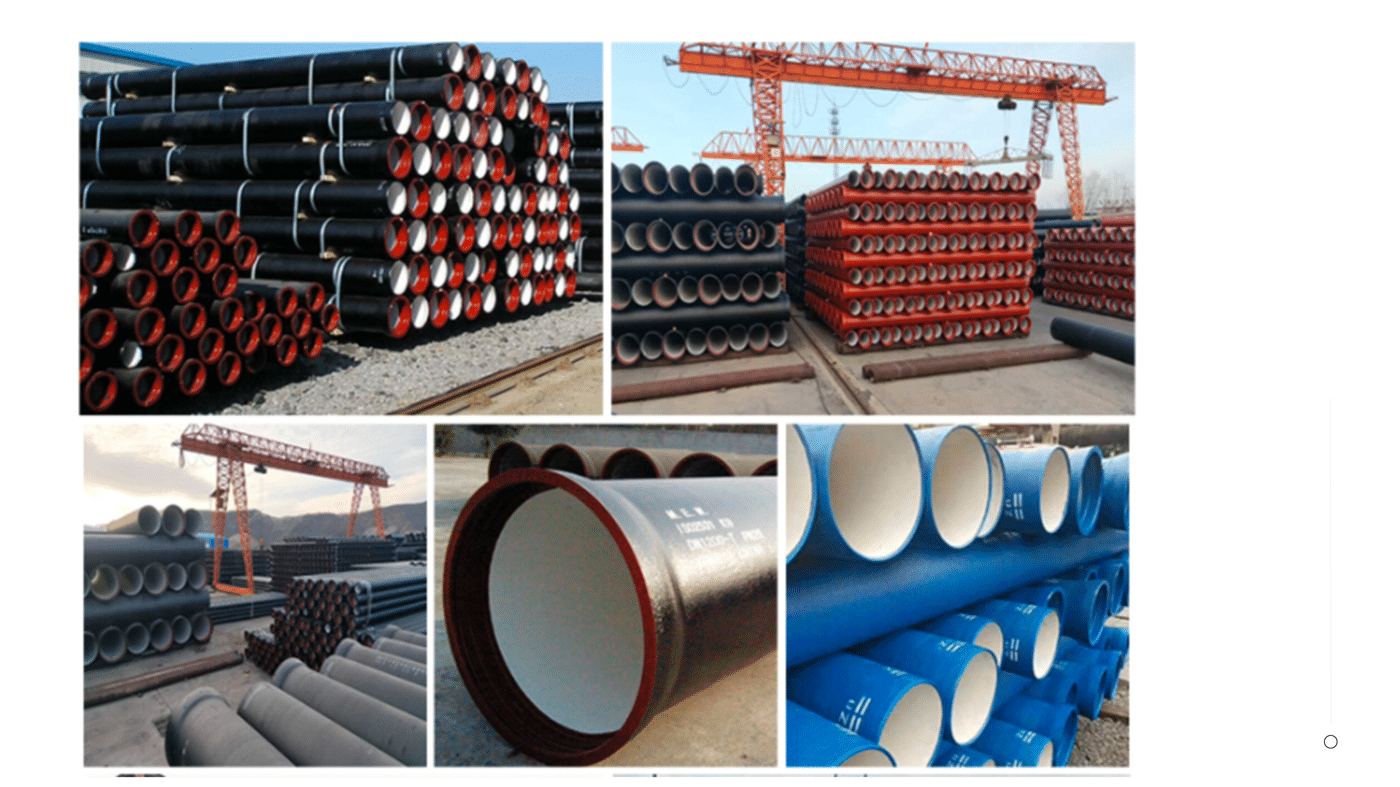

High-Strength Cast Iron Pipe Malleable Nodular Flexible Cast Iron Pipe

Product Detail

The rigid cast iron pipes which are also known as ductile iron or cast iron steel pipes possess the strength of steel and toughness of iron. Graphite is present in spherical form (grades 6 – 7) with a spheroidization degree of 1 – 3 and a rate ≥80%, which can improve the mechanical properties. After heat treatment, the microstructure is predominantly ferrite and small amount of pearlite, which has good wear resistance and high efficiency.

|

All specifications products can be customized according to customer requirements |

|

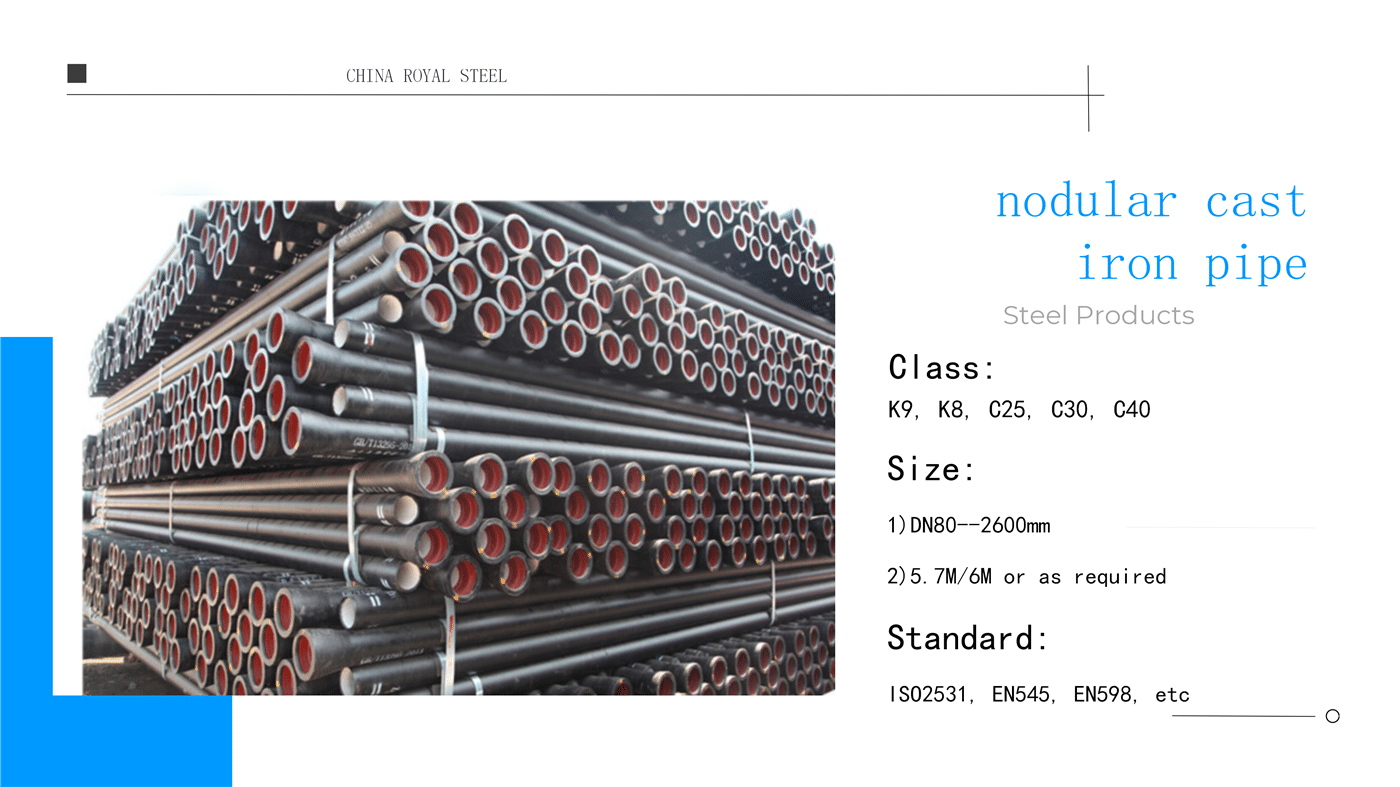

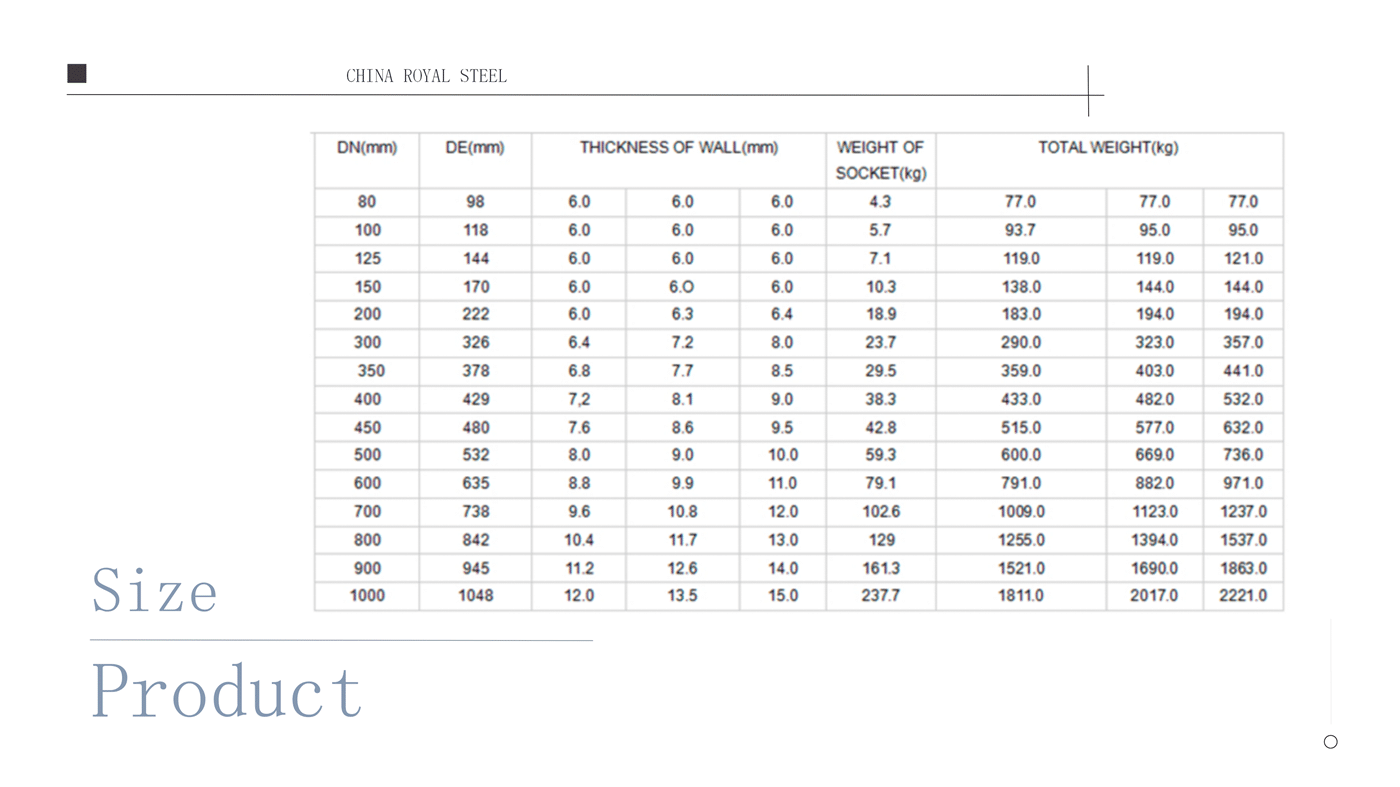

| 1. Size | 1)DN80~2600mm |

| 2)5.7M/6M or as required | |

| 2. Standard: | ISO2531, EN545, EN598, etc |

| 3.Material | Ductile Cast Iron GGG50 |

| 4. Location of our factory | Tianjin,China |

| 5. Usage: | 1)Urban water |

| 2) diversion pipes | |

| 3)agricultural | |

| 6.Internal Coating: | a). Portland cement mortar lining

b). Sulphate Resistant cement mortar lining c). High-Aluminum cement mortar lining d). Fusion bonded epoxy coating e). Liquid epoxy painting f). Black bitumen painting |

| 7.External Coating: | . zinc+bitumen(70microns) painting

. Fusion bonded epoxy coating c). Zinc-aluminum alloy+liquid epoxy painting |

| 8. Type: | Welded |

| 9. Processing Service | Welding, Bending, Punching, Decoiling, Cutting |

| 10. MOQ | 1 Ton |

| 11. Delivery: | Bundles, in bulk, |

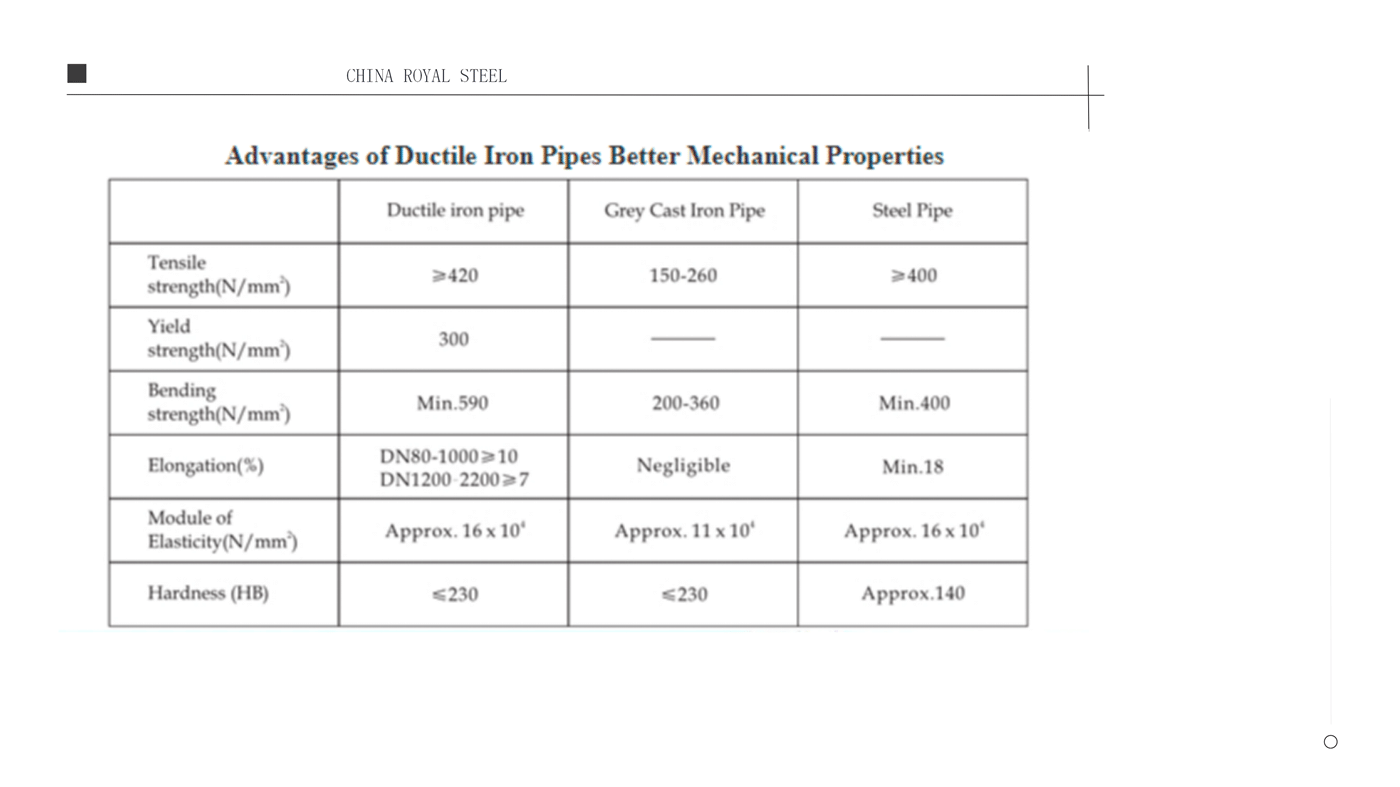

1.Resistance to Internal Pressure: The design pressure is high, and the burst pressure is up to three times that of the working pressure, which can guarantee better security than other materials.

2.Resistance to External Pressure: The high strength of the pipe allows a more reliable and economical installation, since they do not require any special bedding or protective jackets.

3.Inner anti corrosion layer: Smooth, durable and drinking water safe Coating cement mortar lining spun on ISO 4179.

4.Protective layer: Zinc spraying (≥130 g/m2, ISO 8179) and chlorinated resin paint, provide better corrosion resistance. Available also with thicker zinc layer or with zinc-aluminum coating upon customers request.

Features

Ductile iron pipes, a type of cast iron pipe, combine the strength of steel with the toughness of iron. Spheroidization is controlled at levels 1–3 (rate ≥80%) to enhance mechanical properties. Annealed pipes feature a ferrite matrix with minor pearlite, offering excellent corrosion resistance, ductility, sealing performance, and easy installation.

A quantity of nodular graphite are distributed on ferrite and pearlite matrix. The amount of ferrite and pearlite in the matrix structure depend on the nominal diameter and elongation requirements. The amount of pearlite in small diameters is usually not more than 20%, while in large diameters it is usually controlled at about 25%.

Application

Ductile iron pipes are suitable for the potable water (BS EN 545) and sewerage (BS EN 598) systems having diameter range from 80–1600 mm. They are simple to join, can be applied in all weather conditions, frequently without special backfill, and provide a great safety factor with sufficient flexibility to adjust to ground motion, thus they are recommended for various pipeline uses.

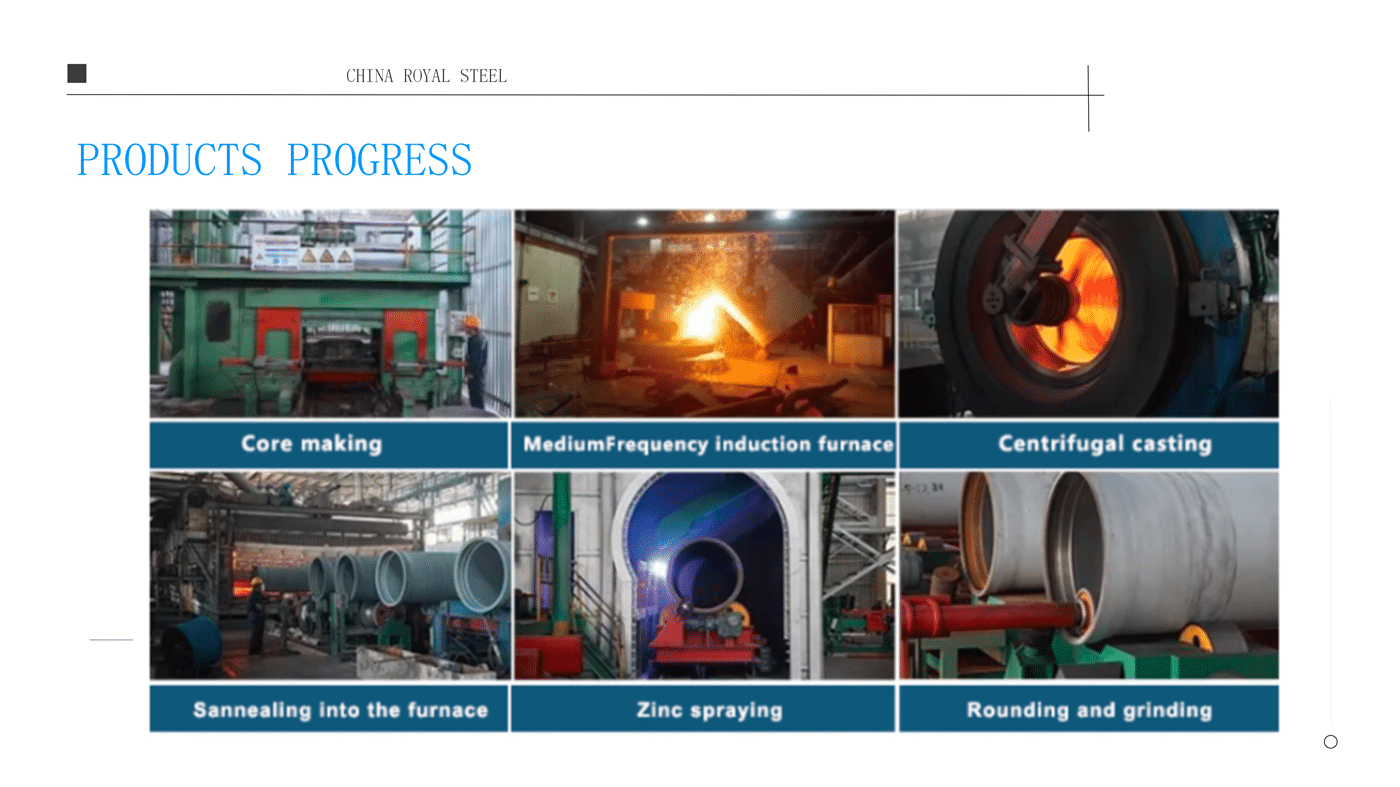

Production Process

Packaging & Shipping

FAQ

-

How can I get a quotation?

Leave us a message, and we will respond promptly. -

Will you deliver on time?

Yes, we ensure high-quality products and timely delivery. Honesty is our core principle. -

Can I get samples before ordering?

Yes, samples are usually free and can be produced based on your samples or technical drawings. -

What are your payment terms?

Typically, 30% deposit with the balance paid against B/L. -

Do you accept third-party inspection?

Yes, we fully accept third-party inspections. -

How can we trust your company?

We have years of experience as a gold supplier in the steel industry. Our headquarters is in Tianjin, and we welcome any verification or investigation.