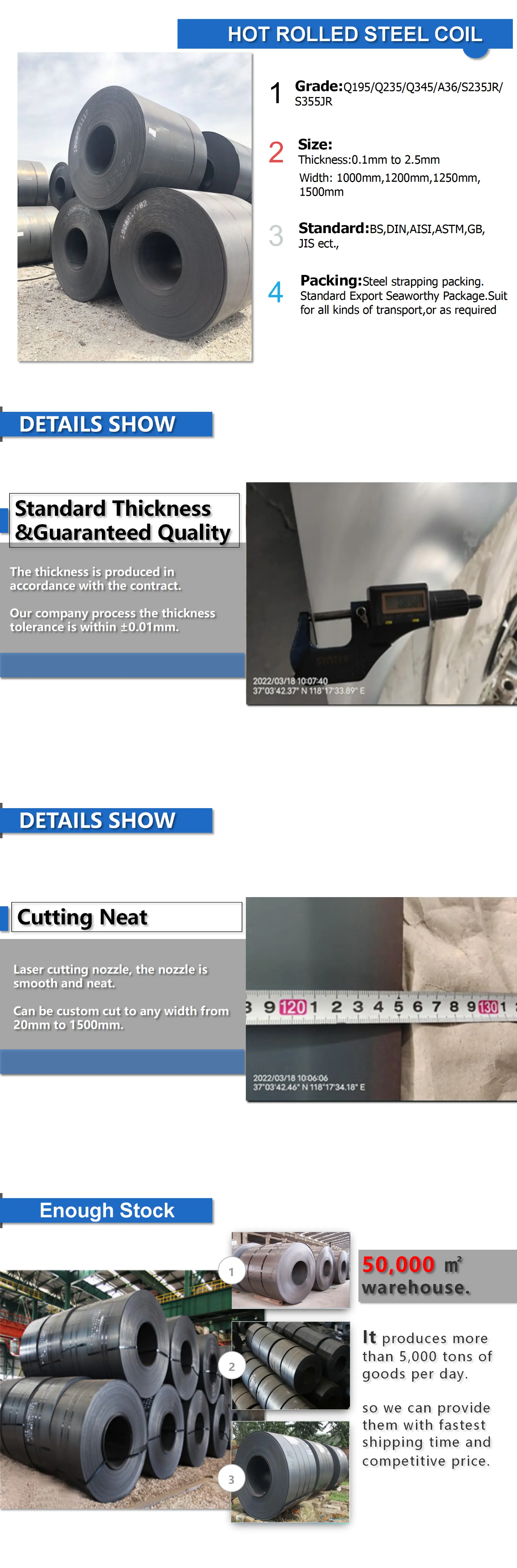

Hot Rolled Steel Coil Q195 Q215 St37 S235jr S355jr Ss400 Steel Coil Top Quality Carbon Steel Coil

Product Detail

|

Product Name |

Hotselling Best Quality A Large Amount Hot Rolled Steel Coil |

|

Material |

Q195/Q235/Q345/A36/S235JR/S355JR |

|

Thickness |

1.5mm~24mm |

|

Size |

3x1219mm 3.5x1500mm 4x1600mm 4.5x2438mm customized |

|

Standard |

ASTM A53-2007, ASTM A671-2006, ASTM A252-1998, ASTM A450-1996, ASME B36.10M-2004, ASTM A523-1996, BS 1387, BS EN10296, BS |

| 6323, BS 6363, BS EN10219, GB/T 3091-2001, GB/T 13793-1992, GB/T9711 | |

|

Grade |

A53-A369, Q195-Q345, ST35-ST52 |

| Grade A, Grade B, Grade C | |

|

Technique |

Hot rolled |

|

Packing |

Bundle, or with all kinds of colors PVC or as your requirements |

|

Pipe Ends |

Plain end/Beveled,protected by plastic caps on both ends, cut quare,grooved,threaded and coupling,etc. |

|

MOQ |

1 Tons, more quantity price will be lower |

|

Surface Treatment |

1. Mill finished /Galvanized /stainless steel |

| 2. PVC,Black and color painting | |

| 3. Transparent oil,anti-rust oil | |

| 4. According to clients requirement | |

|

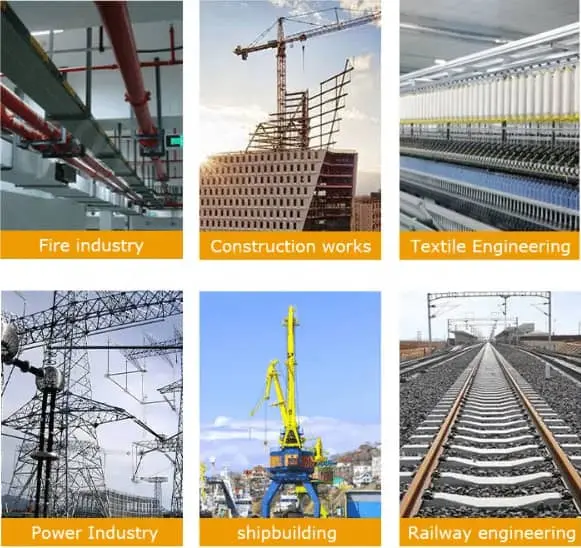

Product Application |

1. Manufacturing of building structures, |

| 2. lifting machinery, | |

| 3. engineering, | |

| 4. agricultural and construction machinery, | |

|

Origin |

Tianjin China |

|

Certificates |

ISO9001-2008,SGS.BV,TUV |

|

Delivery Time |

Usually within 10-15 days after receipt of advance payment |

Main Application

1.Fluid / Gas delivery, Steel structure, Construction;

2.ROYAL GROUP ERW/Welded round carbon steel pipes, which with Highest quality and strong supply ability are widely used in Steel structure and Construction.

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

Size Chart

| Thickness(mm) | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | customized |

| Width(mm) | 800 | 900 | 950 | 1000 | 1219 | 1000 | customized |

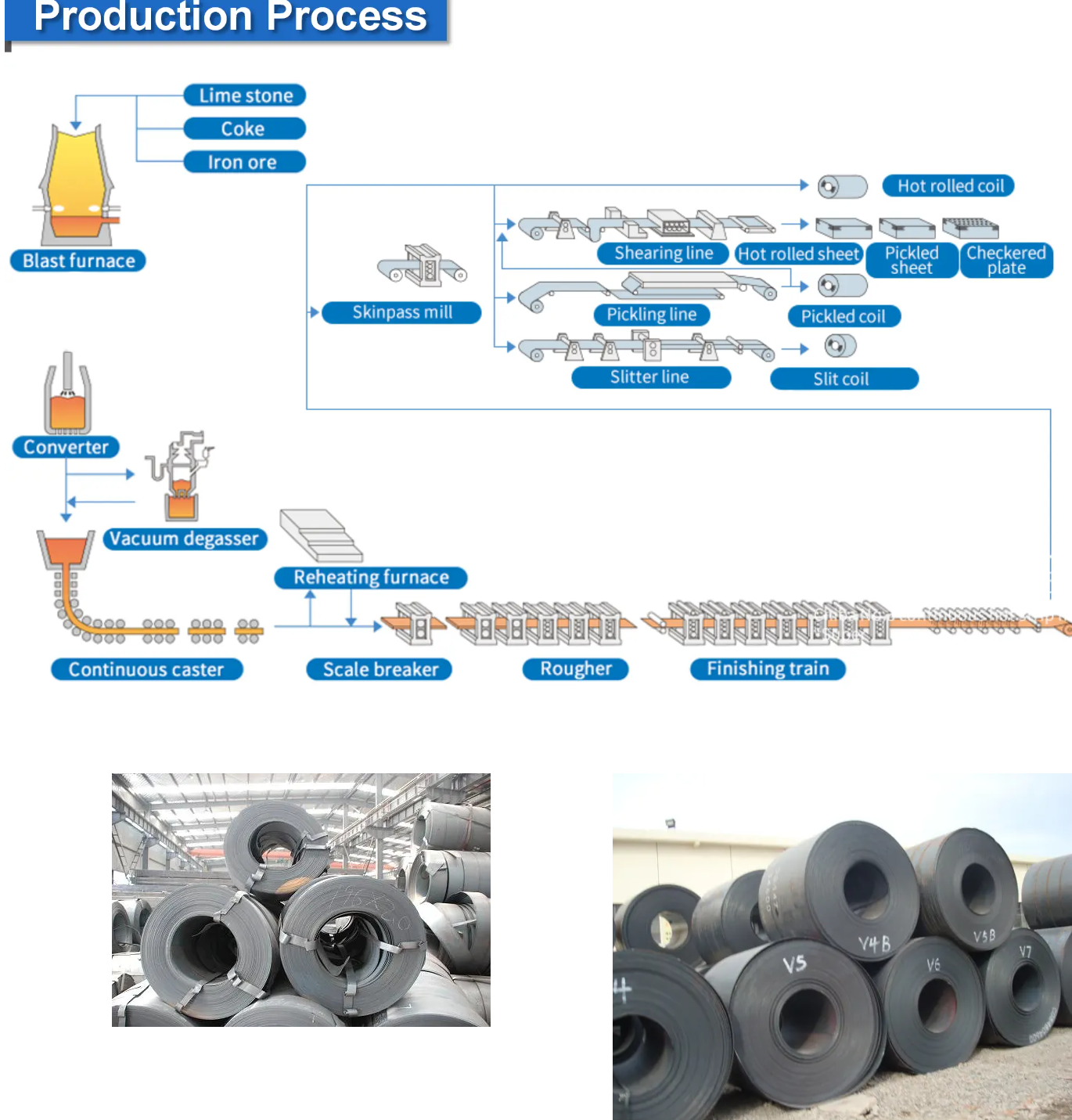

Process of production

The production process of hot-rolled steel coil is a key link in steel manufacturing. It mainly forms the steel billet into the required plate shape through high-temperature rolling. The following are its core steps:

Raw Material Preparation

Continuously cast or bloomed slabs are used as raw material, typically with a thickness of 150-300 mm.

The slab surface is cleaned (e.g., flame cleaning or mechanical grinding) to remove scale and defects to ensure rolling quality.

Heating

The slab is fed into a walking beam furnace and heated to 1100-1300°C to reach the austenitizing temperature and improve plasticity.

Heating time and temperature uniformity are controlled to avoid overheating or underheating.

Roughing

The slab is reduced to a thickness of 30-50 mm in a reversing roughing mill (e.g., a two- or four-high mill) to form an intermediate bar.

After each rolling pass, high-pressure water descaling may be performed to remove the surface oxide layer.

Finishing

The intermediate bar enters the finishing mill (usually consisting of six or seven four- or six-high mills) where it is gradually reduced to the target thickness (e.g., 1.2-25 mm) through continuous rolling. Automatic Gauge Control (AGC) and a shape control system are used to ensure dimensional accuracy and flatness.

During the rolling process, the rolls require cooling and lubrication to prevent thermal deformation and wear.

Cooling

A laminar cooling system is used to rapidly cool the steel strip from the final rolling temperature (approximately 800°C) to room temperature by controlling the water volume and cooling rate (e.g., 30-50°C/second).

The cooling process directly affects the microstructure (e.g., the ratio of ferrite to pearlite) and mechanical properties of the steel coil.

Coiling

The steel strip is coiled into a coil using pinch rolls and a coiler. The tension is controlled at 100-500 N/mm² to ensure a tight coil shape and no loose coils.

The coiling temperature is typically controlled between 550-700°C to optimize performance.

Post-Processing

Surface treatment: Pickling to remove oxide scale, or coatings such as galvanizing or aluminizing.

Packing and Transportation

Usually bare package

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

FAQ

Q: Are u a manufacturer?

A: Yes, we are a manufacturer. We have our own factory located in Tianjin City, China.

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years gold supplier and accept trade assurance.