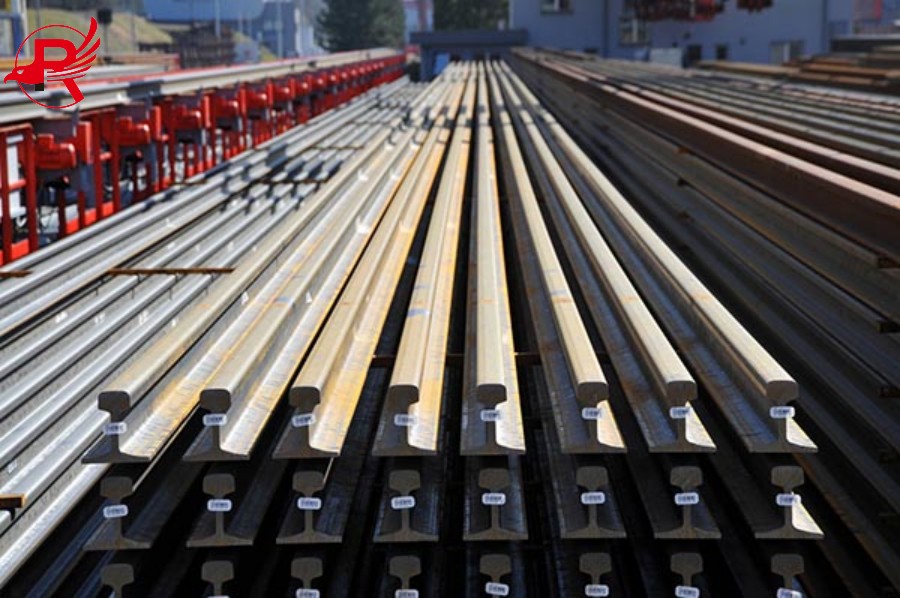

What is steel rail?

Steel Rails are the primary components of railway tracks. Their function is to guide the wheels of rolling stock, bearing the immense pressure exerted by the wheels and transmitting it to the sleepers. Rails must provide a continuous, smooth, and minimally resistant rolling surface for the wheels. On electrified railways or in automatic block sections, rails also serve as track circuits.

Advantages of using steel rails

The exceptional performance of steel rails stems from their unique materials and craftsmanship. Rolled from high-quality carbon steel or low-alloy steel, rails undergo heat treatment processes like quenching and tempering, resulting in a composite structure with a hard, wear-resistant surface and a remarkably tough interior. The surface hardness can reach over HB300, enabling it to withstand the constant pressure and friction of wheels, while the toughness of the core cushions the impact of braking and starting trains, preventing brittle fracture. Furthermore, the rail's cross-sectional design adheres to the principles of mechanics. The I-shaped section ensures sufficient load-bearing strength while reducing its weight, achieving a perfect balance between load-bearing capacity and economic efficiency.

High-quality rails bring multiple advantages to the railway system

First, they offer an exceptionally long service life. High-quality rails are over 30% more wear-resistant than ordinary steel. Under normal operating conditions, they can withstand a total transportation volume exceeding 1 billion tons, significantly reducing the frequency of track replacement.

Second, operational safety. The precise rolling process ensures a smooth rail surface, reducing vibration and noise during train operation and minimizing the risk of cracks caused by rail fatigue.

Finally, they offer reduced maintenance costs. High-quality rails are more corrosion-resistant and stable, reducing the workload of daily grinding and repairs, making railway operations more efficient.

Application of rails in daily life

From an application perspective, steel rails are found in all types of railway systems.

1. On high-speed railways, seamless rail technology extends each section of rail to hundreds of meters, eliminating the jolting effects of track gaps and allowing trains to travel smoothly at speeds exceeding 300 kilometers per hour.

2. Heavy-haul railways rely on high-strength steel rails, carrying 10,000-ton freight trains and playing a key role in the transportation of bulk commodities such as coal and minerals.

3. In urban subways and light rail systems, the precise coordination of rails and track fasteners ensures safety and punctuality during high-density train operations.

4. Even in industrial plants and ports, specially designed lightweight steel rails form the arteries of on-site transportation, facilitating efficient cargo turnover.

The evolution of rails

Though silent, steel rails bear witness to the iterative upgrades of transportation networks. From millimeter-level dimensional accuracy to load-bearing capacity exceeding 10,000 tons, from convenient urban commuting to smooth intercontinental logistics, these long steel bars are more than just physical tracks; they are the "steel blood vessels" that connect regions and drive development. In the future, with advances in materials technology, steel rails will evolve towards greater wear resistance, corrosion resistance, and lightweight construction, continuing to support humanity's relentless pursuit of speed and efficiency.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 15320016383

Post time: Aug-22-2025