Steel sheet piles are steel structures with interlocking mechanisms. By interlocking the individual piles, they form a continuous, tight retaining wall. They are widely used in projects such as cofferdams and foundation pit support. Their main advantages are high strength, ease of driving into hard soil, and a variety of connection styles, such as Larsen and Lackawanna.

What are the types of steel sheet piles

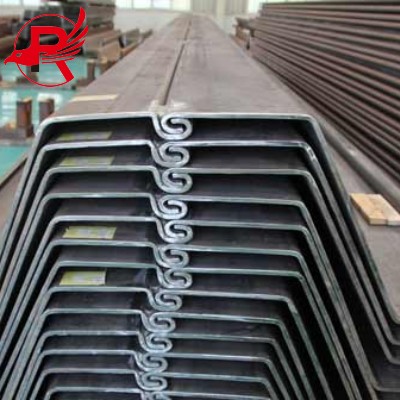

Z-Shaped Steel Sheet Pile:Z-shaped steel sheet piles are hot-rolled or cold-bent steel sections with a "Z"-shaped cross-section, consisting of a web, flanges and locks. Due to their wide flange and thick web structural design, they have excellent bending and shear resistance, and can efficiently withstand lateral soil and water pressures. The locks are located at the ends of the flanges, and after splicing, they can form a highly airtight continuous retaining structure. They also have a large unit weight section modulus, low consumables, and can be reused 3-5 times, with outstanding economy. During construction, piles are sunk by a special pile driver, and can be quickly spliced without additional welding, making them suitable for narrow sites. They are widely used in engineering scenarios such as deep foundation pit support for buildings and subways, waterproofing of water conservancy dams, trench enclosure for municipal pipelines, and temporary flood control and water retention.

U-Shaped Steel Sheet Pile:U-shaped steel sheet piles are hot-rolled or cold-bent steel sections with a "U"-shaped cross-section and symmetrical locking joints. The core consists of a web, two side flanges and end locking joints. The symmetrical structure makes it bear balanced force, and it has both good bending resistance and overall stability. The locking joints are tightly engaged, and after splicing, it can quickly form a continuous retaining and anti-seepage retaining wall. Compared with other types of steel sheet piles, it has a mature production process, lower cost, and can be reused. During construction, the piles can be sunk by a vibration or static pressure pile driver. The operation is convenient and efficient. It is widely used in municipal road trenches, small foundation pit support, temporary drainage cofferdams, river bank protection and temporary construction site walls. It is especially suitable for engineering needs with medium and shallow depths and sensitive to enclosure costs.

What are the properties of steel plate installation

The properties of steel sheet piles cover core dimensions such as material category, mechanical properties and size specifications. Among them, Carbon Steel Sheet Pile is the basic material category, which includes a variety of specific steel grades, such as Q345b Steel Sheet Pile and Sy295 Steel Sheet Pile under the Chinese standard. The former is a low-alloy high-strength steel with a yield strength ≥345MPa and qualified impact toughness at room temperature, and balanced comprehensive mechanical properties. The latter is an ordinary strength carbon steel sheet pile with a yield strength ≥295MPa and excellent plasticity and weldability. There is also the European standard S355jo Steel Sheet Pile, with a yield strength ≥355MPa and -20℃ impact toughness that meets the standard, and excellent low-temperature performance. In terms of size specifications, 600*360 Steel Sheet Piles represents a large-section model with a cross-section width of 600mm and a height of 360mm, which has strong lateral pressure resistance. 12m Steel Sheet Pile refers to a length of 12m. The medium and long specifications can reduce splicing and improve anti-seepage. These steel sheet piles with different properties can be adapted to various scenarios ranging from small and medium-sized temporary projects to deep foundation pits, cold area projects, etc.

Application of steel sheet piles in daily life

Protecting public spaces and infrastructure

Preventing floods and protecting shorelines: Along rivers, lakes, and coastlines, steel sheet piles form seawalls, bulkheads, and flood barriers that protect homes, businesses, and public areas from erosion and rising water levels.

Strengthening bridges and roadways: Sheet piles are used to build and reinforce bridge abutments and retaining walls for roads and railways. This helps stabilize embankments and foundations, ensuring the safety of daily travel.

Constructing underground facilities: Steel sheet piles are vital for creating underground structures like subways, public tunnels, and utility pump houses. They provide crucial support for the excavation and create a waterproof barrier for the finished structure.

Supporting commercial and residential buildings

Building foundations: Steel sheet piling is often used to construct permanent foundation walls, especially for buildings with basements or underground parking garages. This is common in urban areas with limited space and high water tables.

Creating below-grade spaces: Homeowners, particularly in densely populated areas, can use steel sheet piling to construct subterranean extensions or basements. These walls minimize soil disturbance and can be made watertight.

Remediation and environmental protection

Containing contaminated soil: In urban regeneration projects, steel sheet piles can be driven into the ground to create an impervious enclosure. This prevents harmful pollutants and contaminated materials in the soil from spreading.

Creating environmental barriers: Sheet pile walls can be used to contain hazardous materials and protect groundwater supplies from contamination.

Innovative uses

Energy sheet piles: An emerging application combines steel sheet piling with heat exchanger systems. The piles, which are already in the ground, can be used to tap into near-surface geothermal energy for a building's heating and cooling.

When it comes to buying suitable steel sheet piles, choosing a high-quality Steel Sheet Pile Manufacturer is the key.

China Royal Corporation Ltd

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 15320016383

Post time: Sep-12-2025