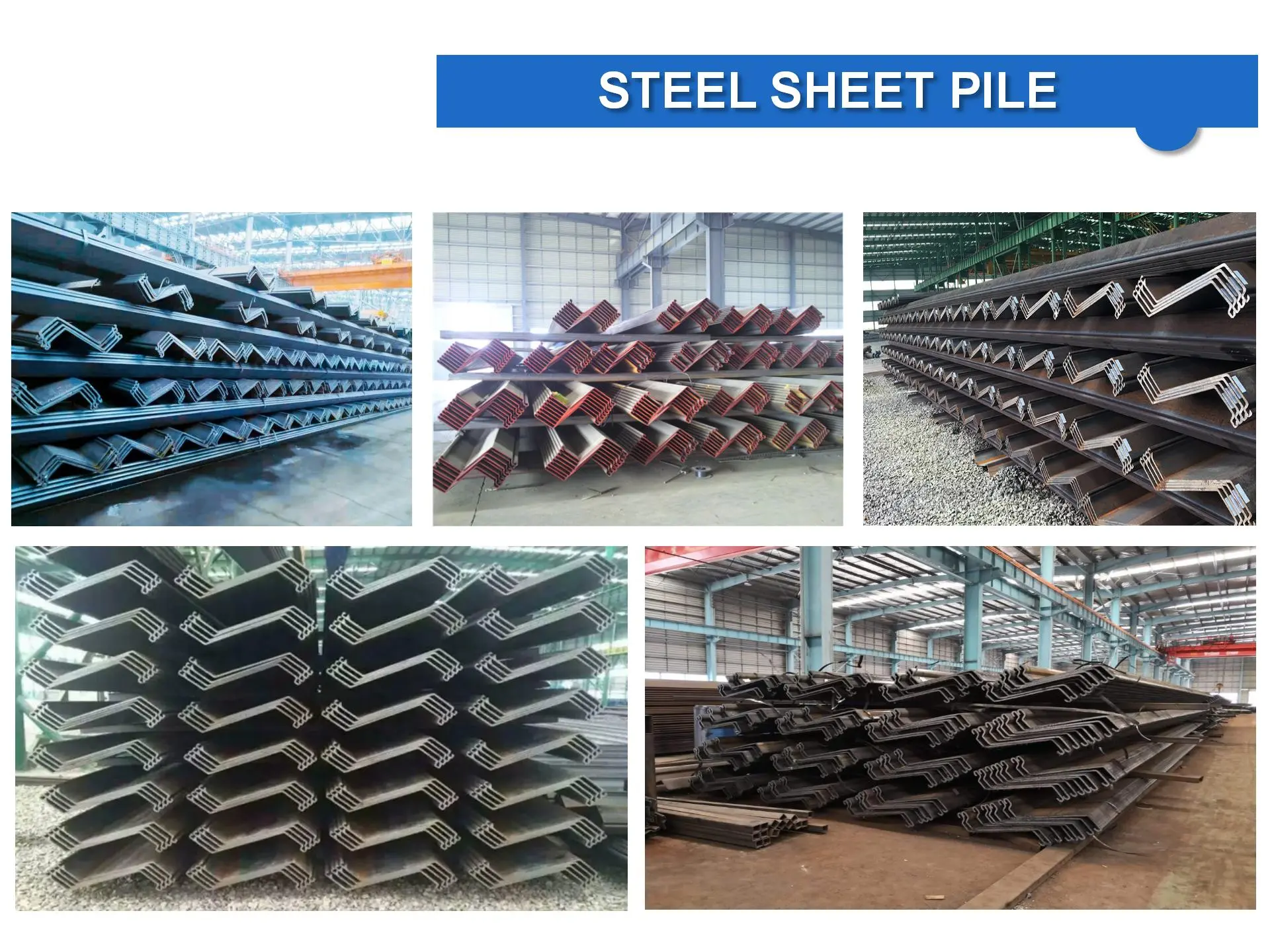

Z Dimension Cold Formed Steel Sheet Pile

Product Detail

|

Product Name

|

sheet pile z type |

| Technique | cold rolled / hot rolled |

| Shape | Z Type / L Type / S Type / Straight |

| Standard | GB/JIS/DIN/ASTM/AISI/EN ect. |

| Material | Q234B/Q345B |

| JIS A5523/ SYW295,JISA5528/SY295,SYW390,SY390 ect. | |

| Application | Cofferdam /River flood diversion and control/ |

| Water treatment system fence/Flood protection /Wall/ | |

| Protective embankment/Coastal berm/Tunnel cuts and tunnel bunkers/ | |

| Breakwater/Weir Wall/ Fixed slope/ Baffle wall | |

| Length | 6m,9m,12m,15m or customized |

| Max.24m | |

| Diameter | 406.4mm-2032.0mm |

| Thickness | 6-25mm |

| Sample | Paid provided |

| Lead time | 7 to 25 working days after the receipt of 30% deposit |

| Payment terms | 30%TT for deposit, 70% balance before shipment or LC at sight |

| Packing | Standard export packing or according to customer's request |

| MOQ | 25 Ton |

| Package | Bundled |

| Size | Customer's Requst |

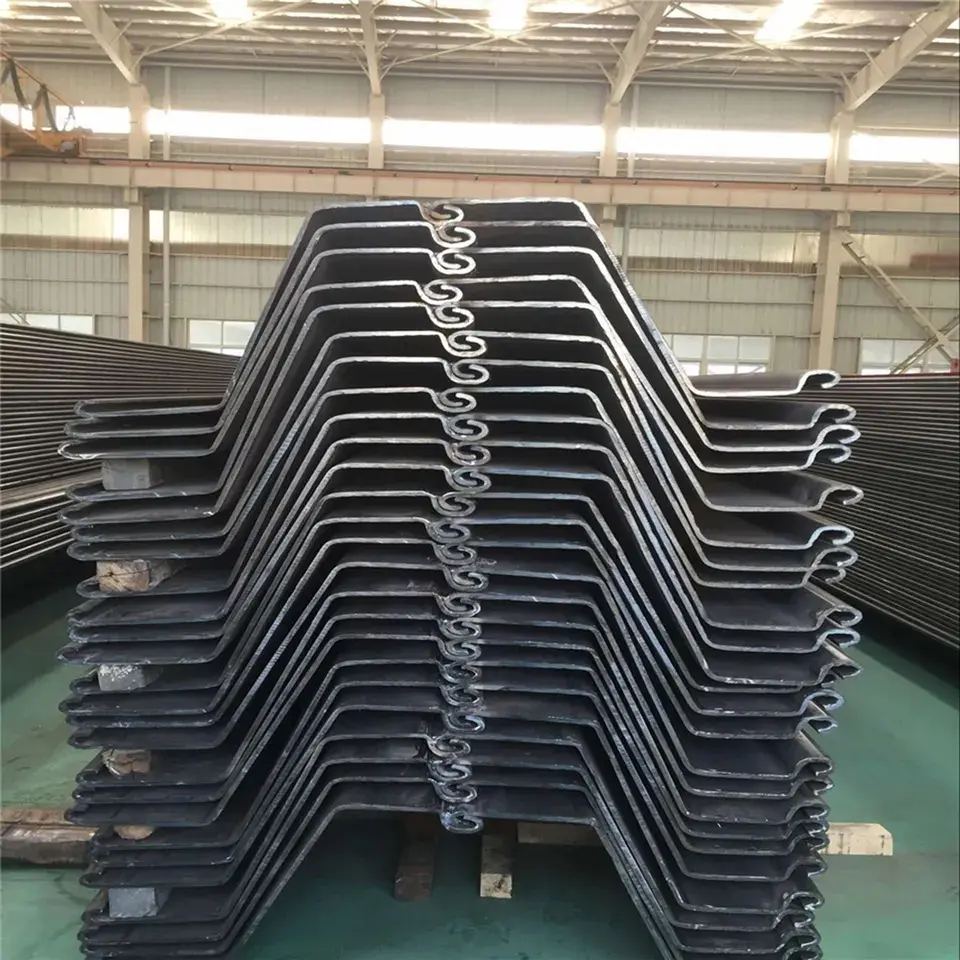

Cold-formed steel sheet piles have two types: non-biting cold-formed steel sheet piles (also known as channel plates) and biting cold-formed steel sheet piles (divided into L-shaped, S-shaped, U-shaped and Z-shaped). Production process: The thin sheet (commonly used thickness 8mm ~ 14mm) is continuously rolled and formed in the cold bending unit. Advantages: less investment in the production line, lower production costs, flexible product size control. Disadvantages: the thickness of each part of the pile is the same, the section size cannot be optimized, resulting in the increase of the amount of steel used, the shape of the lock part is difficult to control, the buckle at the connection is not strict, and the water cannot be stopped, and the pile is easy to tear during use

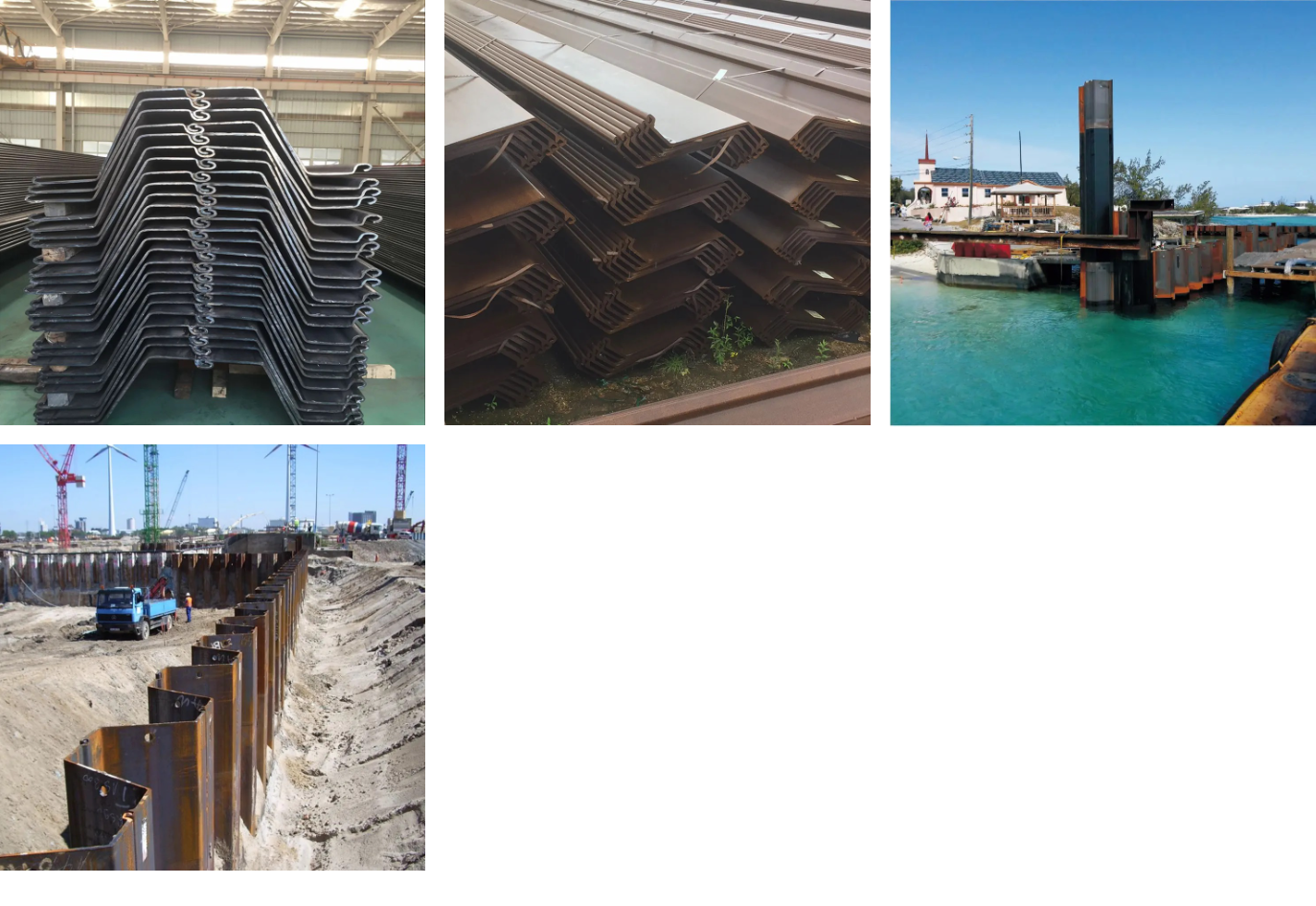

Main Application

steel sheet piles z type are often used in construction projects that require deep excavation, such as roads, bridges, foundation works of buildings, etc. It is known for its durability, strength and ease of installation, making it an excellent choice for many construction projects.

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

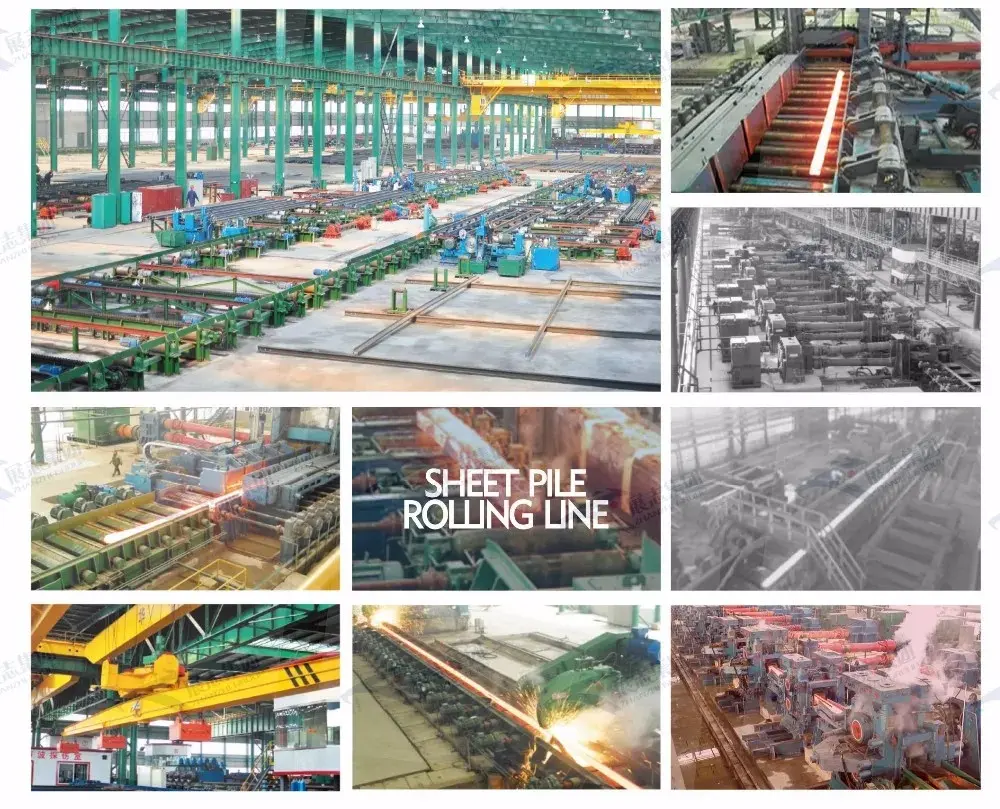

Process of production

Production line of Steel sheet pile rolling line

z shaped sheet pile production is a manufacturing process that involves the creation of Z-shaped steel sheets with interlocking edges. The process begins with the selection of high-quality steel and the cutting of the sheets to the required dimensions. The sheets are then shaped into the distinctive Z-shape using a series of rollers and bending machines. The edges are then interlocked to create a continuous wall of sheet pile. Quality control measures are put in place throughout the production process to ensure the final product meets the necessary standards.

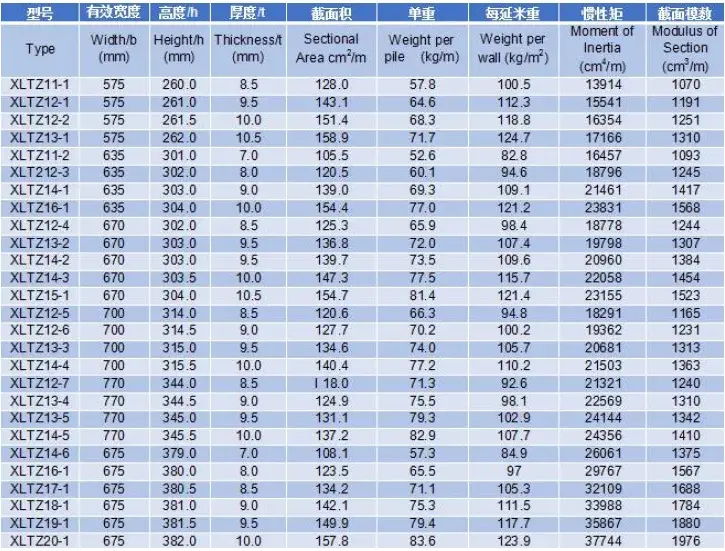

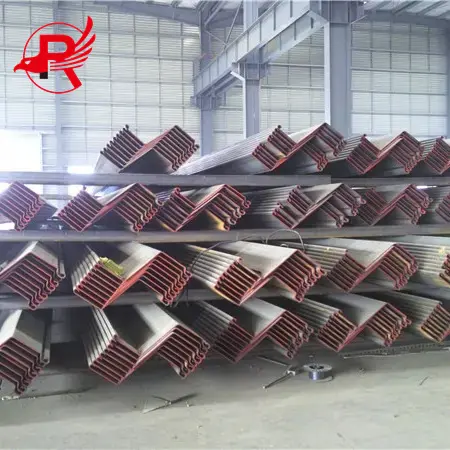

Product Inventory

Packing and Transportation

Packaging is generally naked, steel wire binding, very strong.

If you have special requirements, you can use rust proof packaging, and more beautiful.

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

Our Customer

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.