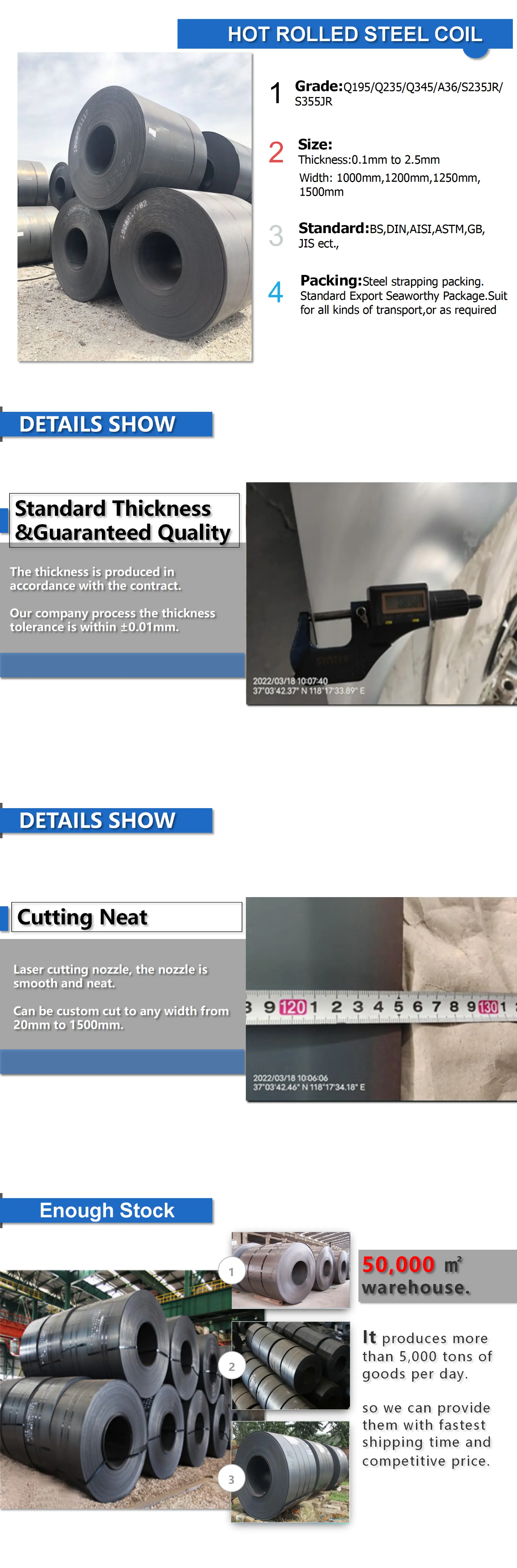

Hot Sale High Quality Steel Coils China Factory Hot Rolled Carbon Steel Coil

Product Detail

|

Product Name |

Hotselling Best Quality A Large Amount Hot Rolled Steel Coil |

|

Material |

Q195/Q235/Q345/A36/S235JR/S355JR |

|

Thickness |

1.5mm~24mm |

|

Size |

3x1219mm 3.5x1500mm 4x1600mm 4.5x2438mm customized |

|

Standard |

ASTM A53-2007, ASTM A671-2006, ASTM A252-1998, ASTM A450-1996, ASME B36.10M-2004, ASTM A523-1996, BS 1387, BS EN10296, BS |

| 6323, BS 6363, BS EN10219, GB/T 3091-2001, GB/T 13793-1992, GB/T9711 | |

|

Grade |

A53-A369, Q195-Q345, ST35-ST52 |

| Grade A, Grade B, Grade C | |

|

Technique |

Hot rolled |

|

Packing |

Bundle, or with all kinds of colors PVC or as your requirements |

|

Pipe Ends |

Plain end/Beveled,protected by plastic caps on both ends, cut quare,grooved,threaded and coupling,etc. |

|

MOQ |

1 Tons, more quantity price will be lower |

|

Surface Treatment |

1. Mill finished /Galvanized /stainless steel |

| 2. PVC,Black and color painting | |

| 3. Transparent oil,anti-rust oil | |

| 4. According to clients requirement | |

|

Product Application |

1. Manufacturing of building structures, |

| 2. lifting machinery, | |

| 3. engineering, | |

| 4. agricultural and construction machinery, | |

|

Origin |

Tianjin China |

|

Certificates |

ISO9001-2008,SGS.BV,TUV |

|

Delivery Time |

Usually within 10-15 days after receipt of advance payment |

Main Application

1.Fluid / Gas delivery, Steel structure, Construction;

2.ROYAL GROUP ERW/Welded round carbon steel pipes, which with Highest quality and strong supply ability are widely used in Steel structure and Construction.

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

Size Chart

| Thickness(mm) | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | customized |

| Width(mm) | 800 | 900 | 950 | 1000 | 1219 | 1000 | customized |

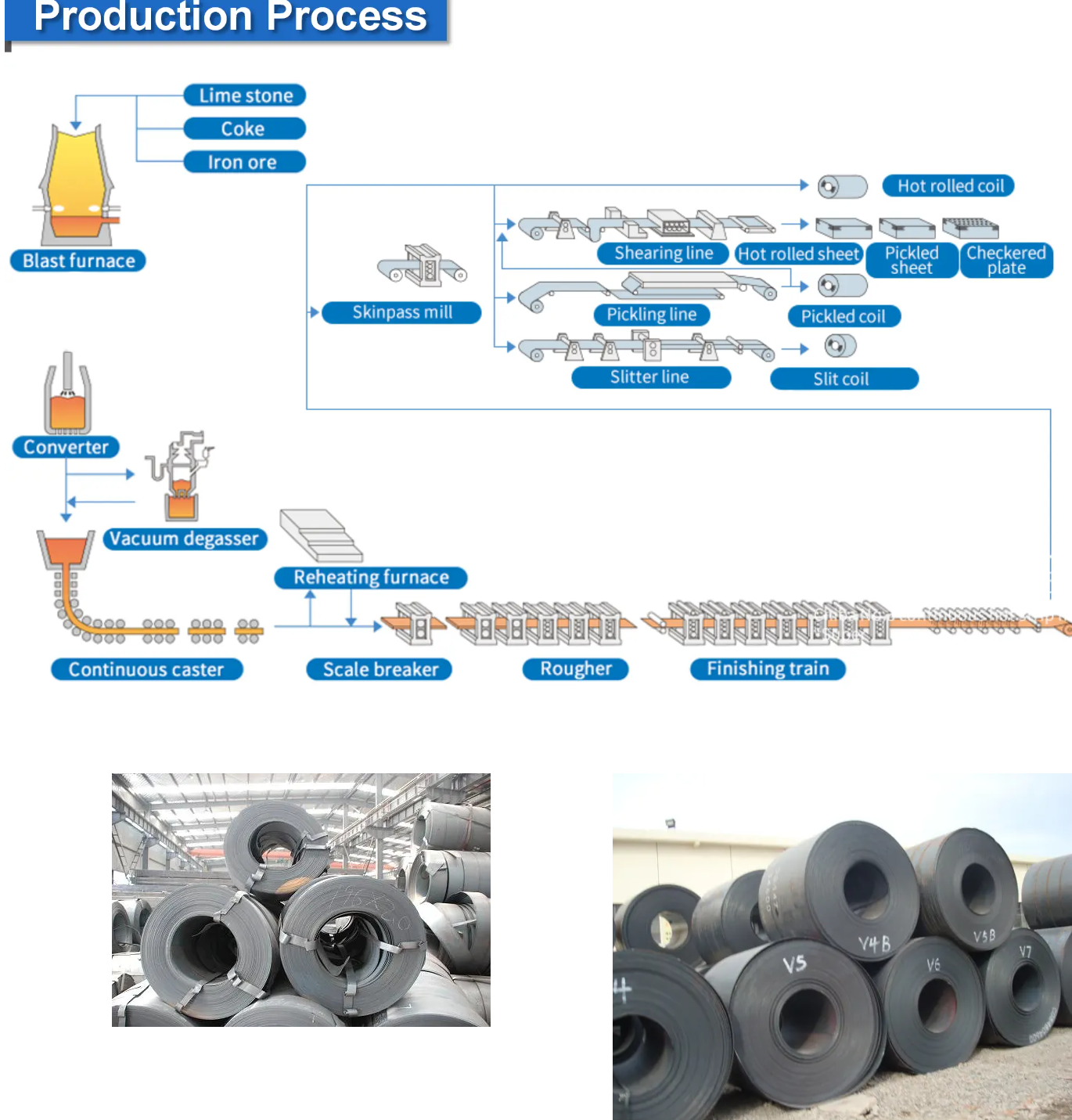

Process of production

The production process of hot-rolled steel coil is a key link in steel manufacturing. It mainly forms the steel billet into the required plate shape through high-temperature rolling. The following are its core steps:

Raw Material Preparation

The raw material is a continuously cast slab or billet, typically 150-300 mm thick.

The slab surface undergoes cleaning (e.g., flame scarfing or mechanical grinding) to remove scale and defects and ensure rolling quality.

Heating

The slab is fed into a walking beam furnace and heated to 1100-1300°C to achieve austenitization and improve ductility.

Heating time and temperature uniformity must be controlled to avoid overheating or underheating.

Roughing

The slab is rolled in a reversing roughing mill (e.g., a two- or four-high mill) into intermediate bars with a thickness of 30-50 mm.

After each rolling pass, high-pressure water descaling may be performed to remove the surface oxide layer.

Finishing

The intermediate bars enter the finishing mill (typically consisting of six or seven four- or six-high mills), where they are gradually thinned to the target thickness (e.g., 1.2-25 mm) through continuous rolling. Automatic gauge control (AGC) and flatness control systems are used to ensure dimensional accuracy and straightness.

During the rolling process, the rolls require cooling and lubrication to prevent thermal deformation and wear.

Cooling

Laminar cooling systems rapidly cool the strip from the final rolling temperature (approximately 800°C) to room temperature by controlling the amount of water and the cooling rate (e.g., 30-50°C/second).

The cooling process directly affects the coil's microstructure (e.g., the ferrite to pearlite ratio) and mechanical properties.

Coiling

The strip is wound into coils using pinch rolls and a coiler. Tension is controlled between 100-500 N/mm² to ensure a tight coil shape and no loose coils.

Coiling temperatures are typically controlled between 550-700°C to optimize properties.

Post-Processing

Surface treatment: Surface treatments include pickling to remove scale or coatings such as galvanizing or aluminizing.

Annealing: Improves material ductility (e.g., recrystallization annealing before cold rolling). Flattening: Rolling at low pressure eliminates yielding in flat products and improves surface finish.

Quality Inspection and Packaging: Products are inspected for dimensions, mechanical properties, and surface quality before being coiled, bundled, and labeled according to customer specifications.

Packing and Transportation

Usually bare package

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

FAQ

Q: Are u a manufacturer?

A: Yes, we are a manufacturer. We have our own factory located in Tianjin City, China.

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years gold supplier and accept trade assurance.