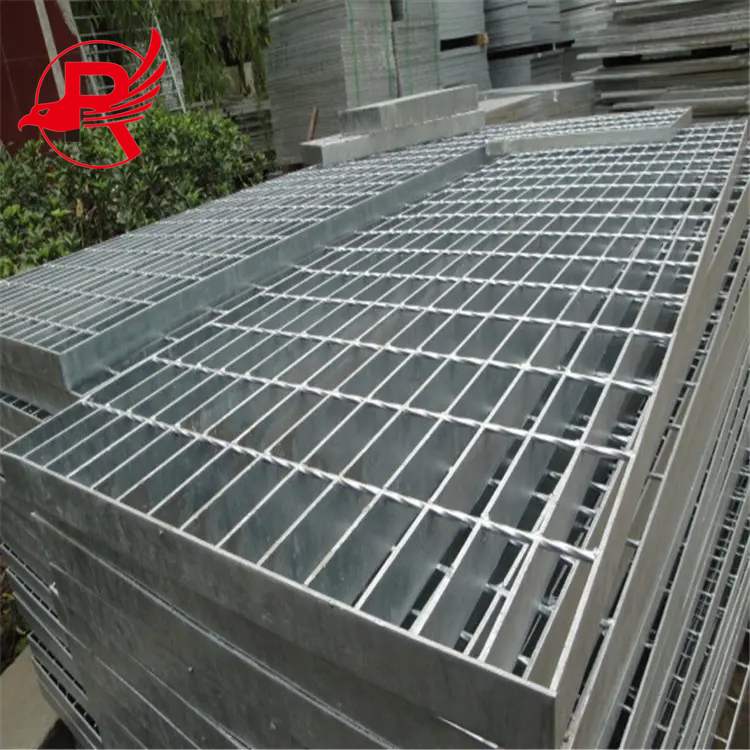

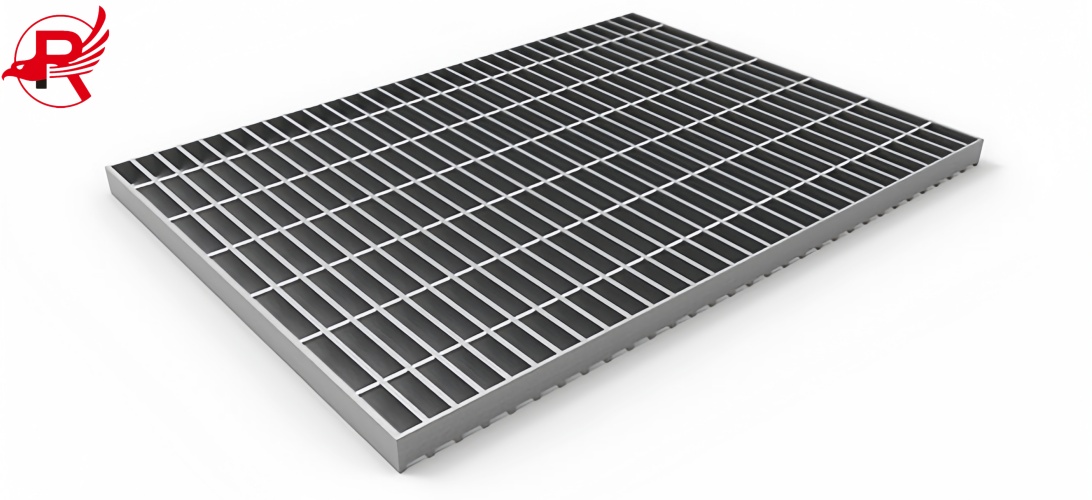

American Steel Structure Accessories ASTM A36 Steel Grating

Product Detail

| Property | Details |

|---|---|

| Material | ASTM A36 Carbon Steel |

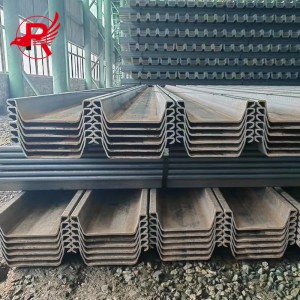

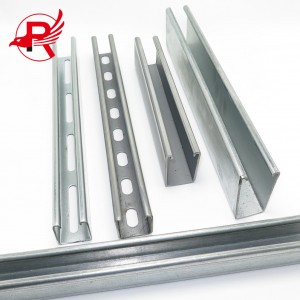

| Type | Flat Bar Grating, Heavy-Duty Grating, Press-Locked Grating |

| Load Bearing Capacity | Customizable based on bearing bar spacing and thickness; available in Light, Medium, Heavy duty |

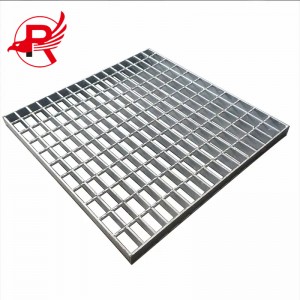

| Mesh / Opening Size | Common sizes: 1" × 4", 1" × 1"; can be customized |

| Corrosion Resistance | Depends on surface treatment; galvanized or painted for enhanced corrosion protection |

| Installation Method | Fixed with support bars or bolted; suitable for flooring, platforms, stair treads, walkways |

| Applications / Environment | Industrial plants, warehouses, chemical platforms, outdoor walkways, pedestrian bridges, stair treads |

| Weight | Varies depending on grating size, bearing bar thickness, and spacing; calculated per square meter |

| Customization | Supports custom dimensions, mesh openings, surface finishes, and load-bearing specifications |

| Quality Certification | ISO 9001 Certified |

| Payment Terms | T/T: 30% Advance + 70% Balance |

| Delivery Time | 7–15 Days |

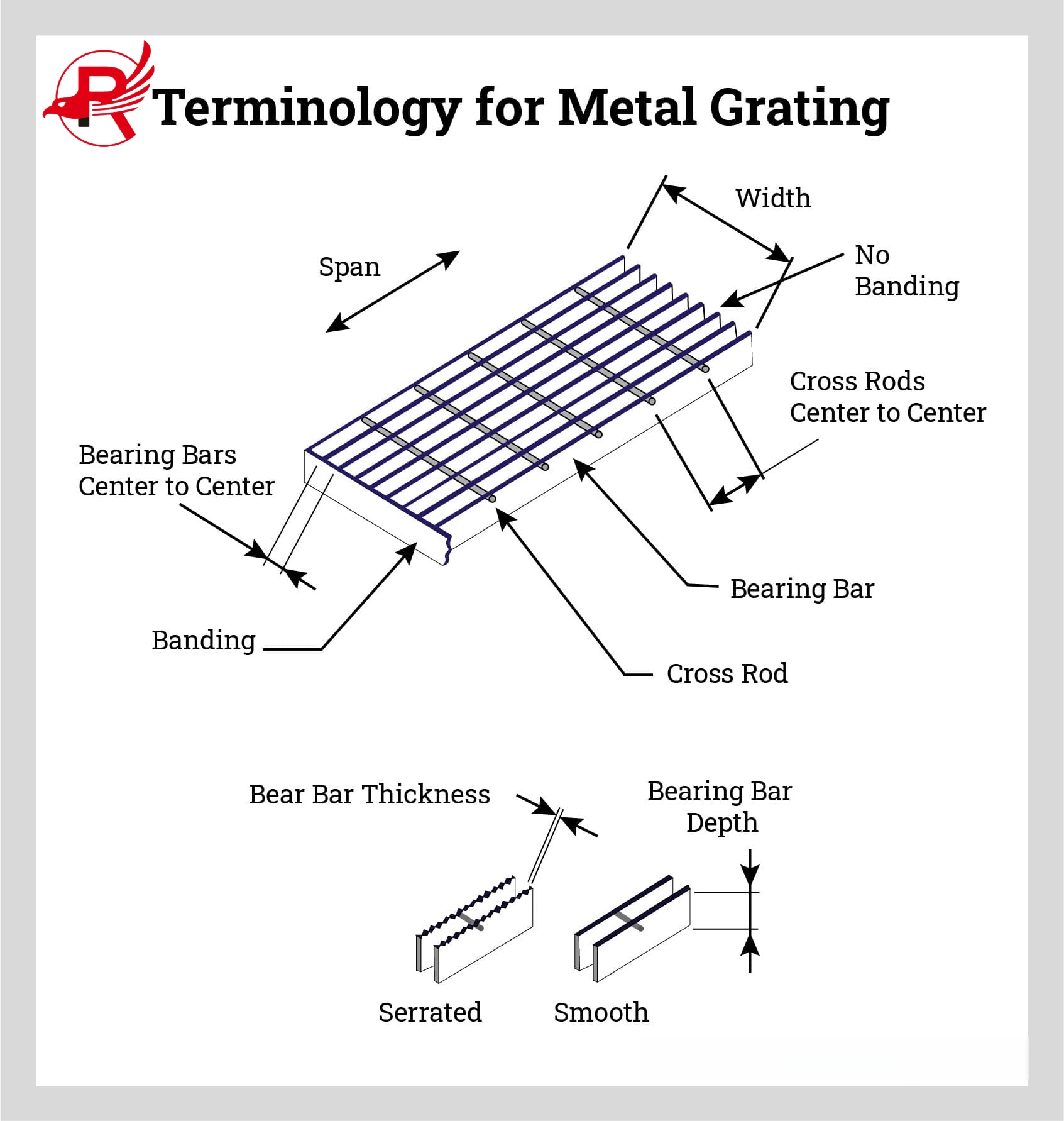

ASTM A36 Steel Grating Size

| Grating Type | Bearing Bar Pitch / Spacing | Bar Width | Bar Thickness | Cross Bar Pitch | Mesh / Opening Size | Load Capacity |

|---|---|---|---|---|---|---|

| Light Duty | 19 mm – 25 mm (3/4"–1") | 19 mm | 3–6 mm | 38–100 mm | 30 × 30 mm | Up to 250 kg/m² |

| Medium Duty | 25 mm – 38 mm (1"–1 1/2") | 19 mm | 3–6 mm | 38–100 mm | 40 × 40 mm | Up to 500 kg/m² |

| Heavy Duty | 38 mm – 50 mm (1 1/2"–2") | 19 mm | 3–6 mm | 38–100 mm | 60 × 60 mm | Up to 1000 kg/m² |

| Extra Heavy Duty | 50 mm – 76 mm (2"–3") | 19 mm | 3–6 mm | 38–100 mm | 76 × 76 mm | >1000 kg/m² |

ASTM A36 Steel Grating Customized Content

| Customization Category | Options Available | Description / Range |

|---|---|---|

| Dimensions | Length, Width, Bearing Bar Spacing | Length: 1–6 m per section (adjustable); Width: 500–1500 mm; Bearing bar spacing: 25–100 mm, depending on load requirements |

| Load & Bearing Capacity | Light, Medium, Heavy, Extra Heavy Duty | Load capacity customizable based on project needs; bearing bars and mesh opening designed to meet structural specifications |

| Processing | Cutting, Drilling, Welding, Edge Treatment | Grating panels can be cut or drilled to specification; edges can be trimmed or reinforced; prefabricated welding available for easier installation |

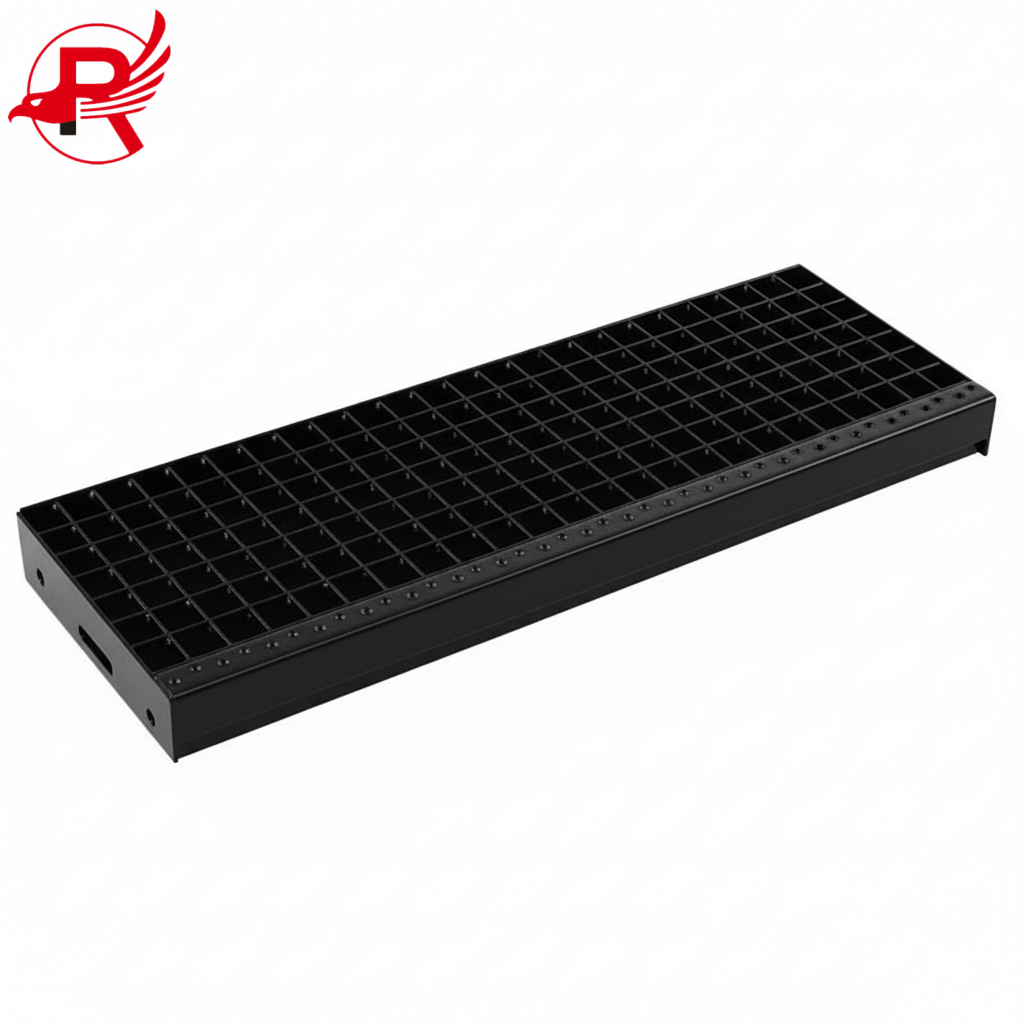

| Surface Treatment | Hot-dip Galvanizing, Powder Coating, Industrial Painting, Anti-slip Coating | Selected based on indoor, outdoor, or coastal environment for corrosion resistance and anti-slip safety |

| Marking & Packaging | Custom Labels, Project Coding, Export Packaging | Labels indicate material grade, dimensions, and project info; packaging suitable for container shipping, flatbed, or local delivery |

| Special Features | Anti-slip Serration, Custom Mesh Patterns | Optional serrated or perforated surfaces for enhanced safety; mesh size and pattern can be customized to meet project or aesthetic requirements |

Surface Finish

Initial Surface

Galvanized Surface

Painted Surface

Application

1.Walkways

Offers a secure walking surface for industrial plant, factory, and warehouse personnel.

The open grid design is slip-resistant and allows dirt, liquids, or debris to fall through.

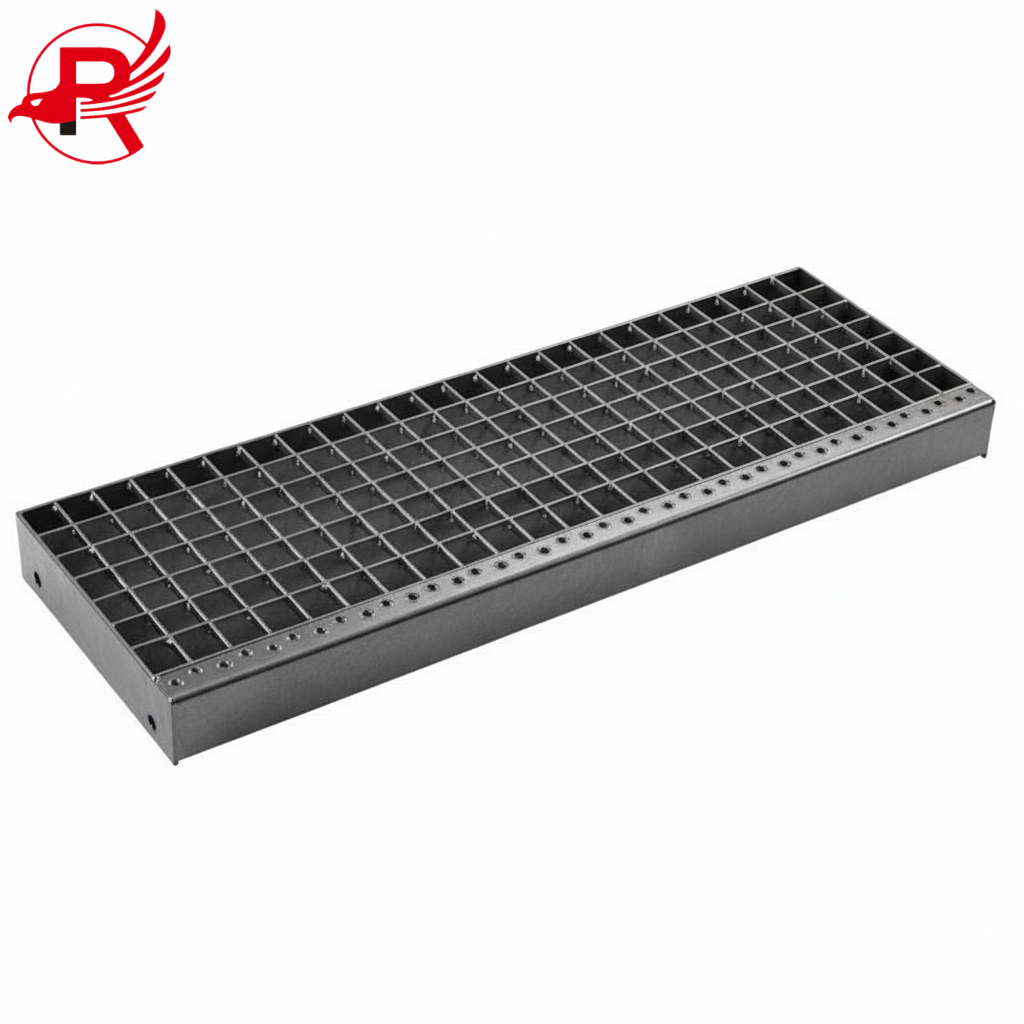

2.Steel Staircases

Perfect for industrial and commercial stair treads where strength and slip resistance are paramount.

Serrated or Anti-slip inserts are available for additional safety.

3.Work Platforms

It is worldwide known that at workshops or in the maintenance areas the machines, the facilities or the people can be supported.

Enables ventilation and provides easy cleaning of work bench.

4.Drainage Areas

Open grating design permits free passage of water, oils and other fluids.

Typically has been applied to open air places, factory ground and by the sides of drainages.

Our Advantages

1.High Strength & Endurance

Constructed of high-grade material ASTM A36 with good load bearing capacity and service life.

2.Personalized Designs

Sizes, mesh, bearing bar center spacing and surface finish can be adapted to suit individual project needs.

3.Resistance to Weathering and Corrosion .

With hot-dip galvanizing, powder coating or industrial painting, suitable for indoor, outdoor or marine environments.

4.Safety & Non-Slip Performance

The anti-slip surface, drainage and ventilation is provided by the open-grid design, making the work place safer.

5.Wide range of Applications

Ideal for all your industrial, commercial and infrastructure projects, whether for walkways and platforms or stairways and work areas and even drainage.

6.Certified ISO 9001 Quality

Produced to high quality standards for reliable performance and consistent results.

7.Swift Delivery & Support

Adaptable production, packaging and delivery options with delivery time: 7-15 days and experienced customer service.

Packaging & Shipping

Packing:

-

Standard Export Packaging: Grating panels are securely bundled with steel straps and reinforced to prevent damage during transportation.

-

Custom Labels & Project Coding: Each bundle can be labeled with material grade, dimensions, and project information for easy identification on-site.

-

Protective Measures: Optional protective covers or wooden pallets are available for delicate surfaces or long-distance shipping.

Delivery:

-

Lead Time: 7–15 days after order confirmation, depending on quantity and customization requirements.

-

Shipping Options: Suitable for container shipment, flatbed transport, or local delivery.

-

Handling & Safety: Packages are designed for safe loading, unloading, and on-site installation.

FAQ

Q1: What material is used for ASTM A36 steel grating?

A: Our steel grating is made from high-strength ASTM A36 carbon steel, ensuring excellent load-bearing capacity and durability.

Q2: Can the grating be customized?

A: Yes, we can customize dimensions, mesh size, bearing bar spacing, surface finish, and load capacity according to project requirements.

Q3: What surface treatments are available?

A: We offer hot-dip galvanizing, powder coating, industrial painting to suit indoor, outdoor, or coastal environments.

Q4: What are the common applications of ASTM A36 steel grating?

A: Walkways, platforms, steel staircases, work platforms, and drainage areas in industrial, commercial, and infrastructure projects.

Q5: How is the grating packaged and shipped?

A: Panels are securely bundled with steel straps, optionally on wooden pallets, and labeled with material grade and project info. Delivery can be by container, flatbed, or local transport.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506