American Steel Structure Accessories ASTM A500 Scaffold Pipe

Product Detail

| Parameter | Specification / Details |

|---|---|

| Product Name | ASTM A500 Scaffold Pipe / Structural Carbon Steel Tube |

| Material | ASTM A500 Structural Carbon Steel |

| Standards | ASTM A500 Grade B / Grade C |

| Dimensions | Outer Diameter: 33.7–60.3 mm (standard) Wall Thickness: 2.5–4.5 mm Length: 6 m, 12 ft, or customized |

| Type | Seamless or ERW (Electric Resistance Welded) Tube |

| Surface Treatment | Black steel, Hot-Dip Galvanized (HDG), Paint / Epoxy coating optional |

| Mechanical Properties | Grade B: Yield Strength ≥315 MPa, Tensile Strength ≥400–550 MPa Grade C: Yield Strength ≥345 MPa, Tensile Strength ≥450–600 MPa |

| Features & Advantages | High structural strength; excellent load-bearing performance; uniform dimensions; suitable for heavy-duty scaffolding and shoring; good weldability |

| Applications | Construction scaffolding, heavy shoring systems, industrial platforms, building framework support |

| Quality Certification | ISO 9001, ASTM compliance |

| Payment Terms | T/T 30% Advance + 70% Balance |

| Delivery Time | 7–15 days |

ASTM A500 Scaffold Pipe Size

| Outer Diameter (mm / in) | Wall Thickness (mm / in) | Length (m / ft) | Weight per Meter (kg/m) | Approx. Load Capacity (kg) | Notes |

|---|---|---|---|---|---|

| 48 mm / 1.89 in | 2.6 mm / 0.102 in | 6 m / 20 ft | 4.7 kg/m | 550–650 | ASTM A500 Grade B, welded |

| 48 mm / 1.89 in | 3.2 mm / 0.126 in | 12 m / 40 ft | 5.8 kg/m | 650–800 | HDG coating optional |

| 50 mm / 1.97 in | 2.8 mm / 0.110 in | 6 m / 20 ft | 5.1 kg/m | 650–750 | Structural grade, welded/ERW |

| 50 mm / 1.97 in | 3.6 mm / 0.142 in | 12 m / 40 ft | 6.8 kg/m | 800–900 | Stronger for heavy platforms |

| 60 mm / 2.36 in | 3.2 mm / 0.126 in | 6 m / 20 ft | 6.4 kg/m | 850–950 | Recommended for vertical posts |

| 60 mm / 2.36 in | 4.5 mm / 0.177 in | 12 m / 40 ft | 9.2 kg/m | 1000–1200 | Heavy-duty load-bearing use |

ASTM A500 Scaffold Pipe Customized Content

ASTM A500 Scaffold Pipe – Customization Options (Rewritten)

| Customization Category | Available Options | Description / Notes |

|---|---|---|

| Dimensions | OD, wall thickness, length ranges | OD: 48–60 mm; WT: 2.5–4.5 mm; Length: 6–12 m customizable |

| Processing | Cutting, threading, bending, accessory welding | Pipes can be modified or fabricated according to site requirements |

| Surface Finish | Black, hot-dip galvanized, epoxy-coated, painted | Choose finish based on corrosion level and installation environment |

| Marking & Packing | Identification tags, project codes, transport-ready packaging | Tags include spec, grade, size; bundles suitable for container or truck shipment |

Surface Finish

Carbon steel surface

Galvanized surface

Painted surface

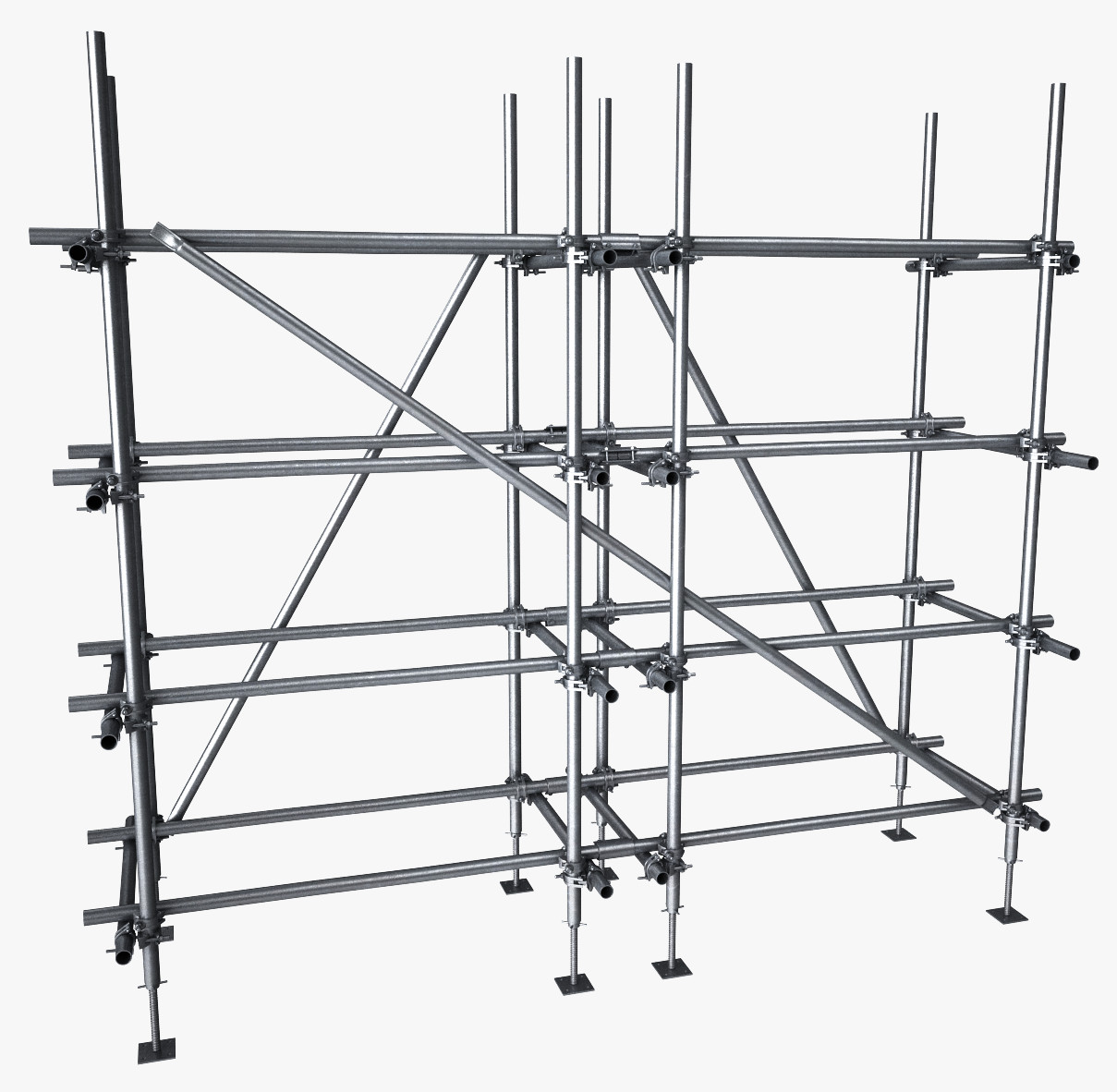

Application

1.Construction & Building Support

Employed as transient working platforms in the building of houses, bridges, and industrial plants, it provides a stable base for workers and supplies.

2.Industrial Access & Maintenance

Excellent for plant or warehouse access walkways and maintenance platforms. Known for its strength and durability.

3.Temporary Load-Bearing Structures

They can also be utilized as props or shoring to bear loads for formwork and other temporary construction frames.

4.Event Platforms & Stage Systems

You can use it to build temporary stages or platforms for concerts, outdoor events, and public gatherings.

5.Residential Maintenance Scaffolds

Ideal for small remodeling job, DIY home repairs or light-duty scaffold systems.

Our Advantages

1.High Strength & Load Capacity

The tubes are made of ASTM-grade carbon steel, making them both lightweight and strong enough to hold heavy loads.

2.Corrosion Protection

Offered in hot-dip galvanized, painted or powder-coated finishes for protection against rust and longer service life.

3.Custom Dimensions

Various diameters, wall thicknesses and lengths can be made to meet customised project requirements.

4.Fast Assembly

Available in standard seamless or welded version for easy on-site mounting.

5.Quality Assurance

Manufactured to ASTM standards and ISO 9001 quality systems for consistent dependability.

6.Low Maintenance Needs

Long-lasting coatings reduce the need for routine maintenance and replacement.

7.Wide Range of Uses

Can be employed for building scaffolds, service platforms, temporary cavity walls, event structures and home applications.

Packaging & Shipping

PACKING

Protection

The scaffold tubes are covered with a waterproof tarpaulin which can keep them dry and clean, no scratches and rust during the process of handling and transportation. You can also add padding like foam or cardboard for a little extra protection.

Securing

The bales are tightly strapped with steel or plastic straps for stability and safety of handling.

Marking & Labeling

All the processed bundles are labeled with material grade, size, batch number and applicable test/inspection reports, that makes it easy to trace.

DELIVERY

Road Transport

The Bundles with Edge protection are loaded on trucks or trailers and tied with anti slip material to prevent shifting during local delivery.

Rail Transport

A multitude of scaffold pipe bundles can be efficiently packed into rail cars for optimal space and protection while long distance transportation.

Sea Freight

Pipe may be delivered by sea in 20ft/40ft container, also open-top container if needed. Inside the container, bundles are lashed to stop moving in the journey.

FAQ

Q1: Alloy of the scaffold tubes?

AThey are fabricated from Carbon Steel and are equal to industry standards for strength and thickness of wall.

Q2 - What surface finishes can I choose?

A: Hot dip galvanizing and other corrosion protection treatments as requested by the project may be applied.

Q3: What size do you have?

A: Available standard sizes of diameter and wall thickness and also customized sizes can be manufactured.

Q4: How do you shipping the pipes package?

ASize Pipes are strung together - and wrapped in waterproof tarpaulin and padded if necessary are tied with strap. Labels contain information on size, grade, batch and inspection.

Q5 Could you tell us the lead time?

A: Delivery time normally 10-15days after the deposit received, the delivery time is subject to the qty and specification.