American Steel Structure Accessories ASTM A572 GR.50 Scaffold Pipe

Product Detail

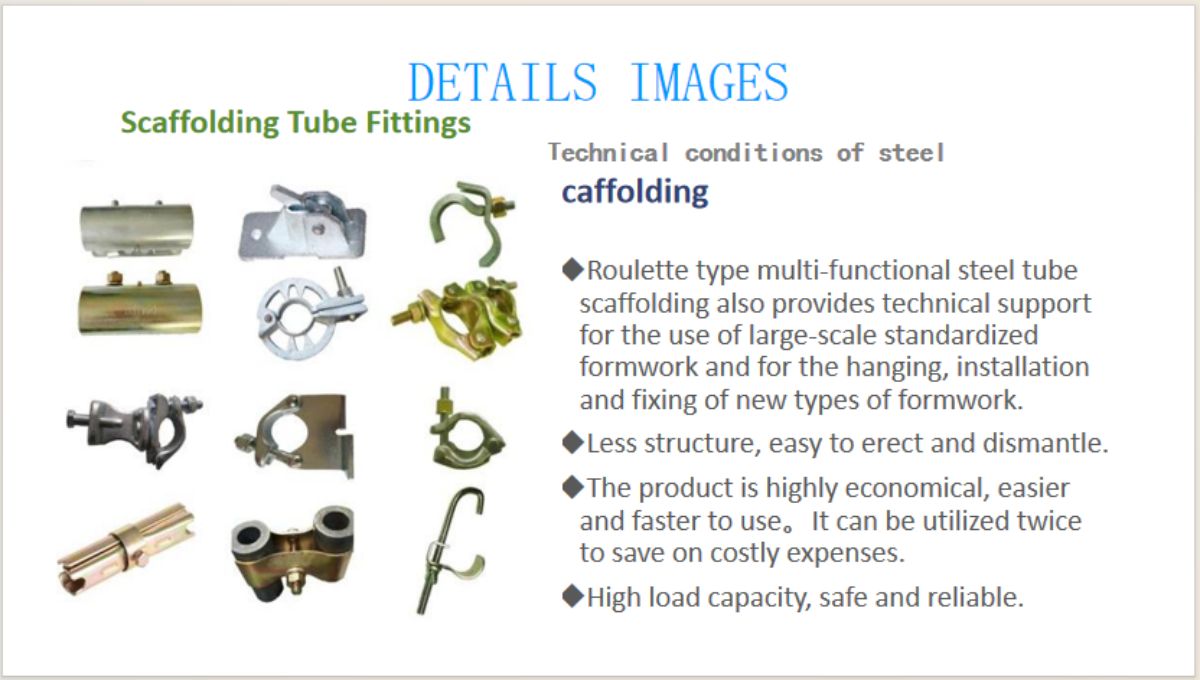

| Parameter | Specification / Details |

|---|---|

| Product Name | ASTM A572 Gr.50 Scaffold Pipe / High-Strength Structural Steel Tube |

| Material | ASTM A572 Grade 50 High-Strength Carbon Steel |

| Standards | ASTM A572 Grade 50 |

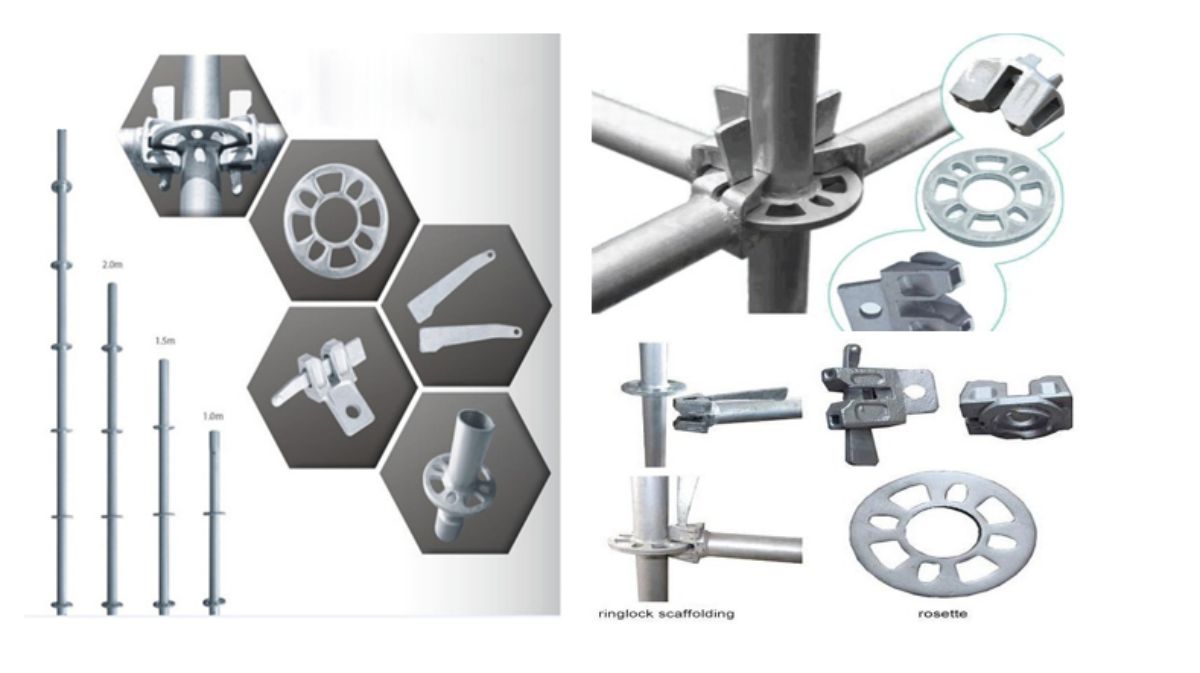

| Dimensions | Outer Diameter: 33.7–60.3 mm; Wall Thickness: 2.5–4.5 mm; Length: 6 m, 12 ft, or customized |

| Type | Seamless or ERW (Electric Resistance Welded) Tube |

| Surface Treatment | Black steel, Hot-Dip Galvanized (HDG), Paint / Epoxy coating optional |

| Mechanical Properties | Yield Strength ≥345 MPa, Tensile Strength ≥450–620 MPa |

| Features & Advantages | High structural strength and durability; excellent load-bearing capacity; uniform dimensions; suitable for heavy-duty scaffolding, shoring, and structural support; good weldability and corrosion resistance (with coating) |

| Applications | Construction scaffolding, industrial platforms, heavy shoring systems, building framework support, temporary structures |

| Quality Certification | ISO 9001, ASTM compliance |

| Payment Terms | T/T 30% Advance + 70% Balance |

| Delivery Time | 7–15 days (depending on quantity and customization) |

ASTM A572 Gr.50 Scaffold Pipe Size

| Outer Diameter (mm / in) | Wall Thickness (mm / in) | Length (m / ft) | Weight per Meter (kg/m) | Approx. Load Capacity (kg) | Notes |

|---|---|---|---|---|---|

| 48 mm / 1.89 in | 2.6 mm / 0.102 in | 6 m / 20 ft | 4.8 kg/m | 600–700 | ASTM A572 Gr.50, welded |

| 48 mm / 1.89 in | 3.2 mm / 0.126 in | 12 m / 40 ft | 5.9 kg/m | 700–850 | HDG coating optional |

| 50 mm / 1.97 in | 2.8 mm / 0.110 in | 6 m / 20 ft | 5.2 kg/m | 700–780 | Structural grade, welded/ERW |

| 50 mm / 1.97 in | 3.6 mm / 0.142 in | 12 m / 40 ft | 6.9 kg/m | 820–920 | Stronger for heavy platforms |

| 60 mm / 2.36 in | 3.2 mm / 0.126 in | 6 m / 20 ft | 6.5 kg/m | 870–970 | Recommended for vertical posts |

| 60 mm / 2.36 in | 4.5 mm / 0.177 in | 12 m / 40 ft | 9.3 kg/m | 1050–1250 | Heavy-duty load-bearing use |

ASTM A572 Gr.50 Scaffold Pipe Customized Content

| Customization Category | Available Options | Description / Notes |

|---|---|---|

| Dimensions | OD, wall thickness, length ranges | OD: 48–60 mm; Wall Thickness: 2.5–4.5 mm; Length: 6–12 m customizable |

| Processing | Cutting, threading, bending, accessory welding | Pipes can be modified or prefabricated according to site requirements and structural needs |

| Surface Finish | Black, hot-dip galvanized, epoxy-coated, painted | Finish can be selected based on corrosion exposure, tropical/humid environments, or aesthetic requirements |

| Marking & Packing | Identification tags, project codes, transport-ready packaging | Tags include specification, grade, and size; bundles packed for container or truck shipment, suitable for long-distance transport |

Surface Finish

Carbon steel surface

Galvanized surface

Painted surface

Application

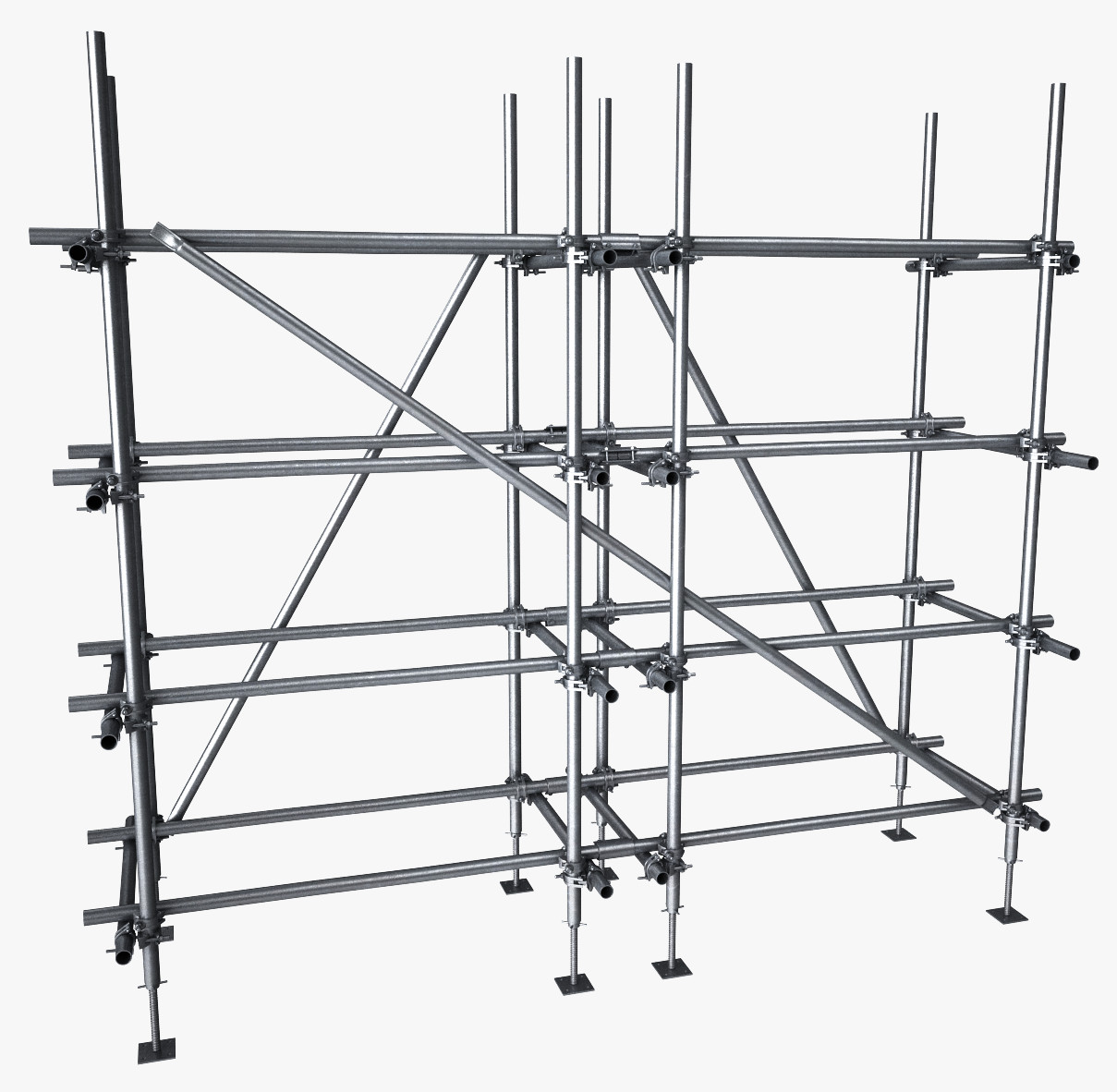

1.Construction & Building Support

Rented as temporary working surfaces for dwellings, bridges, and industrial plants, which they stabilize and supply support to workers and building supplies.

2.Facilities Access & Maintenance

Much appreciated for strength and durability, these are perfect for use as warehouse or plant walkways or maintenance platforms.

3.Temporary Load-Bearing Structures

Be props or shores to bear up formwork and other temporary building systems.

4.Event & Stage Platforms

Recommended for the construction of temporary stages and platforms for concerts, outdoor occasions, or public meetings.

5.Home Maintinence Scaffolds

Great for home renovation and repair projects whether indoors or outdoors.

Our Advantages

1.High Strength & Load Capacity

Constructed from ASTM-grade carbon steel, the lightweight material is robust enough to handle heavy loads.

2.Resistance To Corrosion

In order to stop rust from forming and increase the lifetime of services, it is offered in the form of hot-dip galvanized, painted, or powder-coated finishes.

3.Tailorable Dimensions

Different diameters, wall thicknesses and lengths are available to meet the requirements of your project.

4.Easy to Assemble

Seamless or welded options enable fast and easy installation in the field.

5.Trusted Quality

Manufactured to ASTM standards and ISO 9001 for reliability.

6.Low Maintenance

Strong coatings reduce maintenance and replacement.

7.Wide Range of Applications

Can be applied to scaffolds, services platforms, temporary buildings, event stages and even home projects.

Packaging & Shipping

PACKING

Protection

Scaffold tubes are covered with waterproof tarpaulins to keep them dry and clean, and to avoid scratching and rust during handling and transportation. Additional protection, such as foam or cardboard can be placed on the packaging.

Securing

The packages are tightly bound with steel or plastic bands for stability and safe handling.

Marking & Labeling

The information: material grade, size, batch number and export inspection/test report is included in the label and entire lot is easily traceable and trackable through this.

DELIVERY

Road Transport

Bundles with edge protectors are stacked on trucks or trailers and secured with anti-slip materials to avoid movement in transit for delivery on site.

Rail Transport

Several scaffold pipe bundles can be safely and efficiently loaded into rail cars to maximize space and protect them during long distance transportation.

Sea Freight

Pipes can be sent via 20ft or 40 ft container, including open- top container if required, with bundles tied up to prevent movement in transit.

FAQ

Q1: What is the material of the scaffolding tubes?

A: It is made of carbon steel, the strength and thickness of the wall can meet the industry standard.

Q2: What kind of surface finish can I have?

A: Hot-dip galvanizing or other rust proofing coating could be done when necessary.

Q3: What are the sizes?

A: There are conventional diameters and thickness of the wall available for production. Special sizes also can be produced.

Q4: How do you pack the pipes for shipment?

A: Pipes are bundled, wrapped in waterproof tarpaulin, cushioned if necessary and strapped. Lables contain the size, grade, batch and inspector.

Q5: What is the delivery time?

A: Usually 10-15 days after deposit, according to qty&spec.