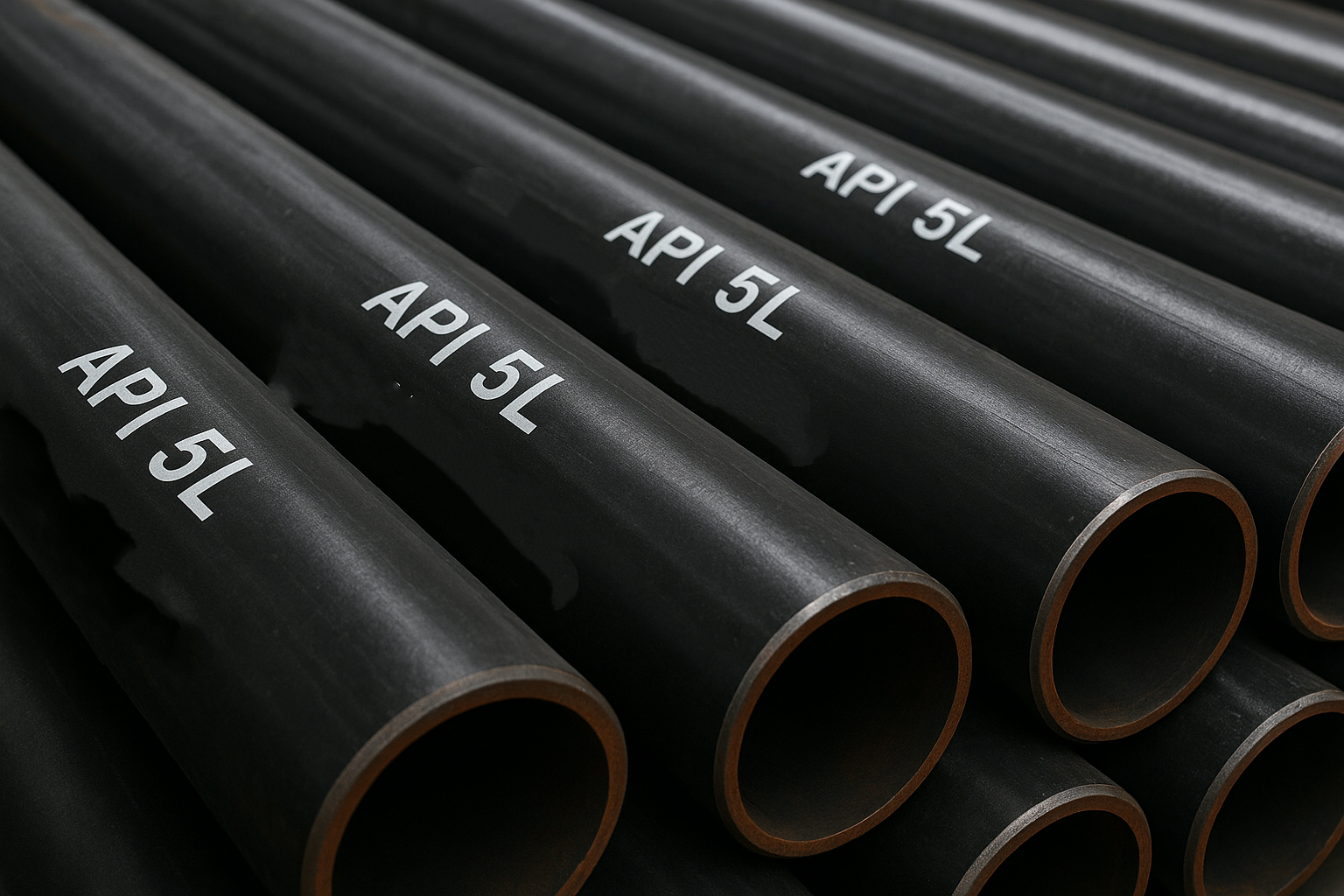

API 5L Grade B X65 Seamless Steel Pipe

Product Detail

| Grades | API 5L Grade B, X65 |

| Specification Level | PSL1, PSL2 |

| Outer Diameter Range | 1/2” to 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16 inches, 18 inches, 20 inches, 24 inches up to 40 inches. |

| Thickness Schedule | SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160 |

| Manufacturing Types | Seamless (Hot Rolled and Cold Rolled), Welded ERW (Electric resistance welded), SAW (Submerged Arc Welded) in LSAW, DSAW, SSAW, HSAW |

| Ends Type | Beveled ends, Plain ends |

| Length Range | SRL (Single Random Length), DRL (Double Random Length), 20 FT (6 meters), 40FT (12 meters) or, customized |

| Protection Caps | plastic or iron |

| Surface Treatment | Natural, Varnished, Black Painting, FBE, 3PE (3LPE), 3PP, CWC (Concrete Weight Coated) CRA Clad or Lined |

Surface Display

Black Painting

FBE

3PE (3LPE)

3PP

Size Chart

| Outside Diameter (OD) | Wall Thickness (WT) | Nominal Pipe Size (NPS) | Length | Steel Grade Available | Type |

| 21.3 mm (0.84 in) | 2.77 – 3.73 mm | ½″ | 5.8 m / 6 m / 12 m | Grade B – X56 | Seamless / ERW |

| 33.4 mm (1.315 in) | 2.77 – 4.55 mm | 1″ | 5.8 m / 6 m / 12 m | Grade B – X56 | Seamless / ERW |

| 60.3 mm (2.375 in) | 3.91 – 7.11 mm | 2″ | 5.8 m / 6 m / 12 m | Grade B – X60 | Seamless / ERW |

| 88.9 mm (3.5 in) | 4.78 – 9.27 mm | 3″ | 5.8 m / 6 m / 12 m | Grade B – X60 | Seamless / ERW |

| 114.3 mm (4.5 in) | 5.21 – 11.13 mm | 4″ | 6 m / 12 m / 18 m | Grade B – X65 | Seamless / ERW / SAW |

| 168.3 mm (6.625 in) | 5.56 – 14.27 mm | 6″ | 6 m / 12 m / 18 m | Grade B – X70 | Seamless / ERW / SAW |

| 219.1 mm (8.625 in) | 6.35 – 15.09 mm | 8″ | 6 m / 12 m / 18 m | X42 – X70 | ERW / SAW |

| 273.1 mm (10.75 in) | 6.35 – 19.05 mm | 10″ | 6 m / 12 m / 18 m | X42 – X70 | SAW |

| 323.9 mm (12.75 in) | 6.35 – 19.05 mm | 12″ | 6 m / 12 m / 18 m | X52 – X80 | SAW |

| 406.4 mm (16 in) | 7.92 – 22.23 mm | 16″ | 6 m / 12 m / 18 m | X56 – X80 | SAW |

| 508.0 mm (20 in) | 7.92 – 25.4 mm | 20″ | 6 m / 12 m / 18 m | X60 – X80 | SAW |

| 610.0 mm (24 in) | 9.53 – 25.4 mm | 24″ | 6 m / 12 m / 18 m | X60 – X80 | SAW |

PRODUCT LEVEL

PSL 1 (Product Specification Level 1): Represents the standard quality for pipes and seamless steel pipe for use in general applications.

PSL 2 (Product Specification Level 2): A superior-grade specification with improved mechanical properties and more rigorous chemical composition controls with full NDT.

PERFORMANCE AND APPLICATION

| API 5L Grade | Key Mechanical Properties (Yield Strength) | Applicable Scenarios in the Americas |

| Grade B | ≥245 MPa | We serve the low-pressure gas pipeline construction industry in North America and small oilfield gathering project in Central America. |

| X42/X46 | >290/317 MPa | Water-pumping systems in the U.S. Midwest and energy grids in South American cities. |

| X52 (Main) | >359 MPa | Serving shale oil pipelines in Texas, onshore oil and gas gathering in Brazil, and cross-border gas transmission projects in Panama. |

| X60/X65 | >414/448 MPa | Transport of oil sands in Canada and medium to high-pressure oil pipelines in the Gulf of Mexico |

| X70/X80 | >483/552 MPa | U.S. cross-country oil pipelines, Brazilian deepwater oil and gas platforms. |

Technological Process

-

Raw Material Inspection – Select and inspect high-quality steel billets or coils.

-

Forming – Roll or pierce the material into pipe shape (Seamless / ERW / SAW).

-

Welding – Join pipe edges by electric resistance or submerged arc welding.

-

Heat Treatment – Improve strength and toughness through controlled heating.

-

Sizing & Straightening – Adjust pipe diameter and ensure dimensional accuracy.

-

Non-Destructive Testing (NDT) – Check for internal and surface defects.

-

Hydrostatic Test – Test each pipe for pressure resistance and leaks.

-

Surface Coating – Apply anti-corrosion coating (Black varnish, FBE, 3LPE, etc.).

-

Marking & Inspection – Mark specifications and perform final quality checks.

-

Packaging & Delivery – Bundle, cap, and ship with Mill Test Certificates.

Our Advantages

Local Branches & Spanish Support: Our branches provide Spanish-language assistance and handle customs clearance for smooth importation.

Reliable Stock: Adequate inventory ensures your orders are fulfilled without delays.

Secure Packaging: Pipes are tightly wrapped and airtight sealed to prevent damage and maintain integrity during transit.

Fast & Efficient Delivery: Worldwide shipping to meet your project deadlines.

Packing and Transportation

Packaging:

Packaging Specifications: API Pipe is shipped on IPPC‑fumigated wooden pallets (meeting Central American quarantine standards), wrapped in a 3-layer waterproof membrane, and fitted with plastic protective caps. Each bundle weighs 2–3 tons, suitable for small cranes on local construction sites.

Customization: Standard length 12 m for container shipping; short-length options of 8 m or 10 m available for mountainous inland transport in Guatemala, Honduras, and nearby regions.

All-Inclusive Documentation: Includes Spanish Certificate of Origin (Form B), MTC material certificate, SGS test report, packing list, and commercial invoice. Any document errors are reissued within 24 hours.

Transportation:

For transit times of “China → Colon Port, Panama (30 days), Manzanillo Port, Mexico (28 days), Limon Port, Costa Rica (35 days),” we provide information on short-distance delivery partners (such as TMM, a local logistics company in Panama) for “port to oil field/construction site”.

FAQ

Q1: Do your API 5L steel pipes meet Americas standards?

A: Yes. Fully compliant with API 5L 45th Revision, ASME B36.10M, and local regulations (Mexico NOM, Panama free trade zone). All certifications (API, NACE MR0175, ISO 9001) are verifiable online.

Q2: Which steel grade is right for my project?

-

Low pressure (≤3 MPa): B or X42 – municipal gas, irrigation.

-

Medium pressure (3–7 MPa): X52 – onshore oil & gas (e.g., Texas shale).

-

High pressure (≥7 MPa) / offshore: X65/X70/X80 – deepwater or high-strength needs.

Tip: Our technical team provides free grade recommendations tailored to your project.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506