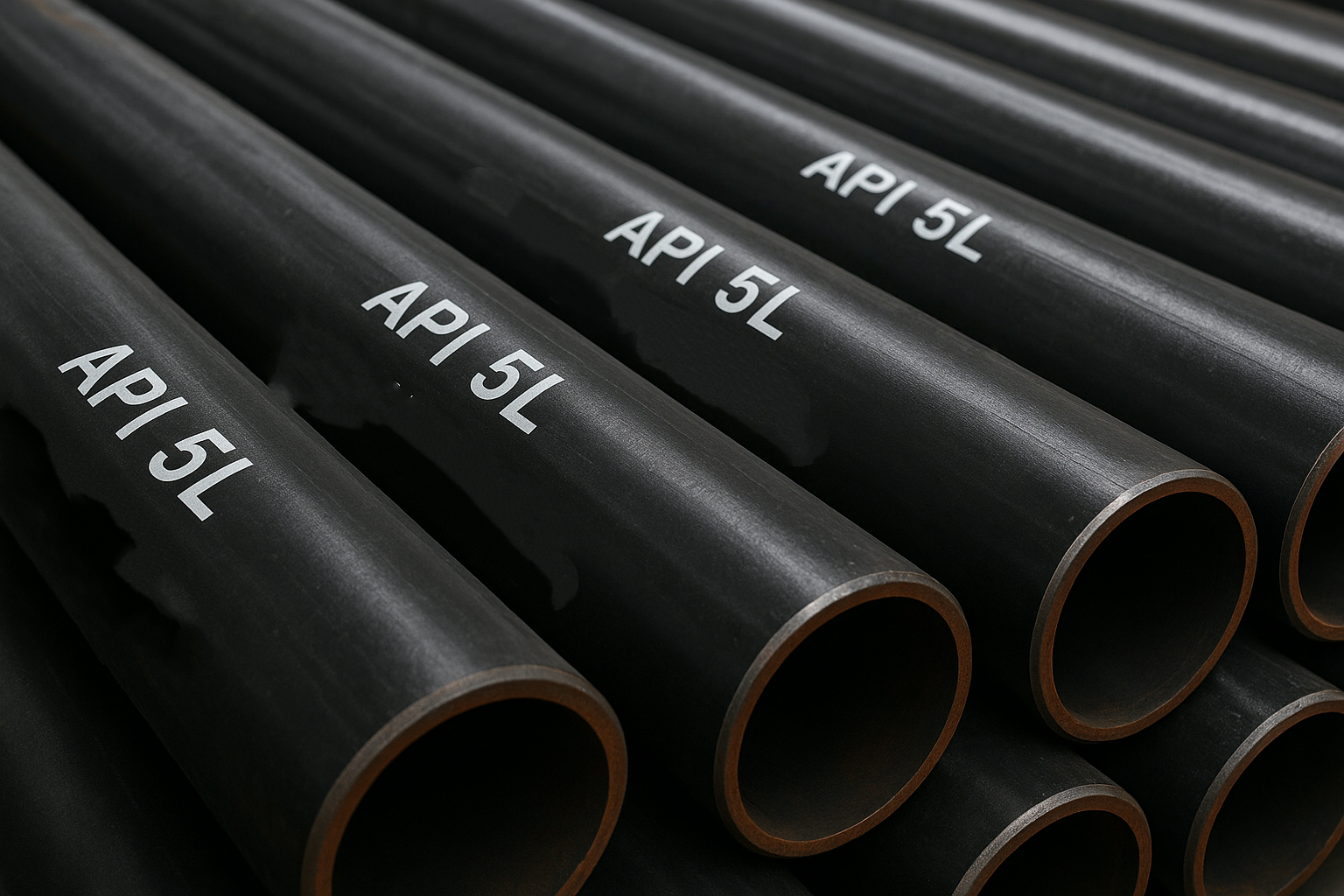

API 5L Grade B X80 Seamless Steel Pipe

Product Detail

| Grades | API 5L Grade B,X70 |

| Specification Level | PSL1, PSL2 |

| Outer Diameter Range | 1/2” to 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16 inches, 18 inches, 20 inches, 24 inches up to 40 inches. |

| Thickness Schedule | SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160 |

| Manufacturing Types | Seamless (Hot Rolled and Cold Rolled), Welded ERW (Electric resistance welded), SAW (Submerged Arc Welded) in LSAW, DSAW, SSAW, HSAW |

| Ends Type | Beveled ends, Plain ends |

| Length Range | SRL (Single Random Length), DRL (Double Random Length), 20 FT (6 meters), 40FT (12 meters) or, customized |

| Protection Caps | plastic or iron |

| Surface Treatment | Natural, Varnished, Black Painting, FBE, 3PE (3LPE), 3PP, CWC (Concrete Weight Coated) CRA Clad or Lined |

Surface Display

Black Painting

FBE

3PE (3LPE)

3PP

Size Chart

| Outside Diameter (OD) | Wall Thickness (WT) | Nominal Pipe Size (NPS) | Length | Steel Grade Available | Type |

| 21.3 mm (0.84 in) | 2.77 – 3.73 mm | ½″ | 5.8 m / 6 m / 12 m | Grade B – X56 | Seamless / ERW |

| 33.4 mm (1.315 in) | 2.77 – 4.55 mm | 1″ | 5.8 m / 6 m / 12 m | Grade B – X56 | Seamless / ERW |

| 60.3 mm (2.375 in) | 3.91 – 7.11 mm | 2″ | 5.8 m / 6 m / 12 m | Grade B – X60 | Seamless / ERW |

| 88.9 mm (3.5 in) | 4.78 – 9.27 mm | 3″ | 5.8 m / 6 m / 12 m | Grade B – X60 | Seamless / ERW |

| 114.3 mm (4.5 in) | 5.21 – 11.13 mm | 4″ | 6 m / 12 m / 18 m | Grade B – X65 | Seamless / ERW / SAW |

| 168.3 mm (6.625 in) | 5.56 – 14.27 mm | 6″ | 6 m / 12 m / 18 m | Grade B – X70 | Seamless / ERW / SAW |

| 219.1 mm (8.625 in) | 6.35 – 15.09 mm | 8″ | 6 m / 12 m / 18 m | X42 – X70 | ERW / SAW |

| 273.1 mm (10.75 in) | 6.35 – 19.05 mm | 10″ | 6 m / 12 m / 18 m | X42 – X70 | SAW |

| 323.9 mm (12.75 in) | 6.35 – 19.05 mm | 12″ | 6 m / 12 m / 18 m | X52 – X80 | SAW |

| 406.4 mm (16 in) | 7.92 – 22.23 mm | 16″ | 6 m / 12 m / 18 m | X56 – X80 | SAW |

| 508.0 mm (20 in) | 7.92 – 25.4 mm | 20″ | 6 m / 12 m / 18 m | X60 – X80 | SAW |

| 610.0 mm (24 in) | 9.53 – 25.4 mm | 24″ | 6 m / 12 m / 18 m | X60 – X80 | SAW |

PRODUCT LEVEL

PSL 1: Standard quality of pipe for plain end line pipe for general use.

PSL 2: A superior quality level with improved mechanical properties, tighter chemical composition limits, and required NDT for greater confidence.

PERFORMANCE AND APPLICATION

| API 5L Grade | Key Mechanical Properties (Yield Strength) | Applicable Scenarios in the Americas |

| Grade B | ≥245 MPa | North American low-pressure gas pipelines and small-scale oilfield gathering networks in Central America. |

| X42/X46 | >290/317 MPa | Agricultural irrigation in the U.S. Midwest, municipal energy networks in South America |

| X52 (Main) | >359 MPa | Texas shale oil pipelines, onshore oil and gas gathering in Brazil, and cross-border gas transmission in Panama. |

| X60/X65 | >414/448 MPa | Oil sands transportation in Canada, medium-to-high pressure pipelines in the Gulf of Mexico |

| X70/X80 | >483/552 MPa | Long-distance oil pipelines in the U.S., deepwater oil & gas platforms in Brazil |

Technological Process

-

Raw Material Inspection – Select and inspect high-quality steel billets or coils.

-

Forming – Roll or pierce the material into pipe shape (Seamless / ERW / SAW).

-

Welding – Join pipe edges by electric resistance or submerged arc welding.

-

Heat Treatment – Improve strength and toughness through controlled heating.

-

Sizing & Straightening – Adjust pipe diameter and ensure dimensional accuracy.

-

Non-Destructive Testing (NDT) – Check for internal and surface defects.

-

Hydrostatic Test – Test each pipe for pressure resistance and leaks.

-

Surface Coating – Apply anti-corrosion coating (Black varnish, FBE, 3LPE, etc.).

-

Marking & Inspection – Mark specifications and perform final quality checks.

-

Packaging & Delivery – Bundle, cap, and ship with Mill Test Certificates.

Our Advantages

Local Branch and Spanish Support: Our regional offices are available to serve you in Spanish, providing you with full Spanish-language support, managing your customs clearance and supervising your import execution from beginning to end.

Good Supply Assurance: We have enough stock, which enable us send your orders as soon as possible.

Safe Packaging: Elbows are packed with multilayer bubble wrap, sealed airtight, then put in corrugated box, this packaging method can protect elbow from being deformed or broken during shipping.

Rapid Worldwide Shipping: We mail internationally and process orders swiftly so that you can meet your project deadlines.

Packing and Transportation

Packaging:

Processing Packaging Pipes are loaded on IPPC-fumigated wooden pallets ( Central American country quarantine standards) and wrapped with a 3-ply waterproof membrane, plastic caps are attached with to top and bottom to avoid dirt and moisture.

Bundle Weight: Small cranes can be used on site to handle 2 to 3 tons per bundle.

Length Options: Standard 12 m pipes (container friendly) and 8 m and 10 m shorter versions for inland transport in mountainous regions such as in Guatemala or Honduras.

Paperwork: We offer Spanish language versions all paperwork including CoO (FORM B), MTC, SGS reports, packing lists and commercial invoices. Any mistake is rectified and reissued in 24 hours.

Transportation:

Transportation & Local Distribution: Delivery from China is about 30days to Colon, Panama and 28 days to Manzanillo, Mexico,35 days to Limón, Costa Rica. We also have local delivery partners (i.e, TMM in Panama) for delivery from port to oil field or construction.

FAQ

1. Do your API 5L pipes meet Americas standards?

Yes. Fully compliant with API 5L 45th Revision, ASME B36.10M, and local regulations (e.g., Mexico NOM, Panama FTZ). Certifications like API, NACE MR0175, ISO 9001 are verifiable online.

2. How to choose the right steel grade?

-

Low-pressure (≤3 MPa): Grade B or X42, cost-effective for municipal gas/irrigation.

-

Medium-pressure (3–7 MPa): X52, ideal for onshore oil/gas (e.g., Texas shale).

-

High-pressure (≥7 MPa) / Offshore: X65–X80, for deepwater or high-stress pipelines.

Our experts can provide free grade recommendations for your project.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506