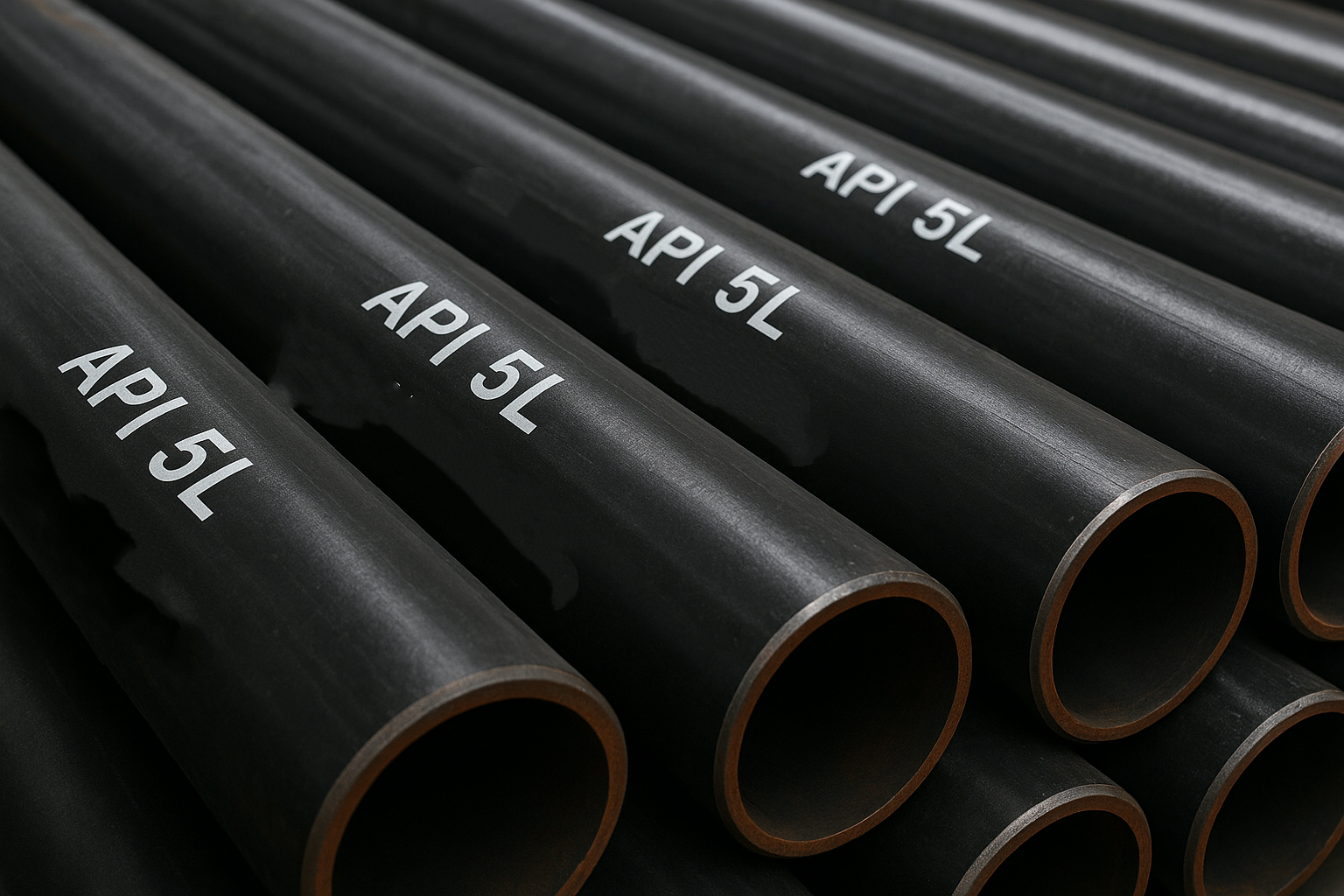

API 5L PSL1 Grade B X42 X50 X60 Seamless Steel Pipe

Product Detail

| Grades | API 5L Grade B, X65 |

| Specification Level | PSL1, PSL2 |

| Outer Diameter Range | 1/2” to 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16 inches, 18 inches, 20 inches, 24 inches up to 40 inches. |

| Thickness Schedule | SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160 |

| Manufacturing Types | Seamless (Hot Rolled and Cold Rolled), Welded ERW (Electric resistance welded), SAW (Submerged Arc Welded) in LSAW, DSAW, SSAW, HSAW |

| Ends Type | Beveled ends, Plain ends |

| Length Range | SRL (Single Random Length), DRL (Double Random Length), 20 FT (6 meters), 40FT (12 meters) or, customized |

| Protection Caps | plastic or iron |

| Surface Treatment | Natural, Varnished, Black Painting, FBE, 3PE (3LPE), 3PP, CWC (Concrete Weight Coated) CRA Clad or Lined |

Surface Display

Black Painting

FBE

3PE (3LPE)

3PP

Size Chart

| Outside Diameter (OD) | Wall Thickness (WT) | Nominal Pipe Size (NPS) | Length | Steel Grade Available | Type |

| 21.3 mm (0.84 in) | 2.77 – 3.73 mm | ½″ | 5.8 m / 6 m / 12 m | Grade B – X56 | Seamless / ERW |

| 33.4 mm (1.315 in) | 2.77 – 4.55 mm | 1″ | 5.8 m / 6 m / 12 m | Grade B – X56 | Seamless / ERW |

| 60.3 mm (2.375 in) | 3.91 – 7.11 mm | 2″ | 5.8 m / 6 m / 12 m | Grade B – X60 | Seamless / ERW |

| 88.9 mm (3.5 in) | 4.78 – 9.27 mm | 3″ | 5.8 m / 6 m / 12 m | Grade B – X60 | Seamless / ERW |

| 114.3 mm (4.5 in) | 5.21 – 11.13 mm | 4″ | 6 m / 12 m / 18 m | Grade B – X65 | Seamless / ERW / SAW |

| 168.3 mm (6.625 in) | 5.56 – 14.27 mm | 6″ | 6 m / 12 m / 18 m | Grade B – X70 | Seamless / ERW / SAW |

| 219.1 mm (8.625 in) | 6.35 – 15.09 mm | 8″ | 6 m / 12 m / 18 m | X42 – X70 | ERW / SAW |

| 273.1 mm (10.75 in) | 6.35 – 19.05 mm | 10″ | 6 m / 12 m / 18 m | X42 – X70 | SAW |

| 323.9 mm (12.75 in) | 6.35 – 19.05 mm | 12″ | 6 m / 12 m / 18 m | X52 – X80 | SAW |

| 406.4 mm (16 in) | 7.92 – 22.23 mm | 16″ | 6 m / 12 m / 18 m | X56 – X80 | SAW |

| 508.0 mm (20 in) | 7.92 – 25.4 mm | 20″ | 6 m / 12 m / 18 m | X60 – X80 | SAW |

| 610.0 mm (24 in) | 9.53 – 25.4 mm | 24″ | 6 m / 12 m / 18 m | X60 – X80 | SAW |

PRODUCT LEVEL

PSL 1 (Product Specification Level 1): It is the basic quality for pipes and seamless steel pipe for general applications.

PSL 2 (Product Specification Level 2): A higher-grade specification with enhanced mechanical properties and stricter chemical composition limits with full NDT.

PERFORMANCE AND APPLICATION

| API 5L Grade | Key Mechanical Properties (Yield Strength) | Applicable Scenarios in the Americas |

| Grade B | ≥245 MPa | We serve the low-pressure gas pipeline construction industry in North America and small oilfield gathering project in Central America. |

| X42/X46 | >290/317 MPa | Water-pumping systems in the U.S. Midwest and energy grids in South American cities. |

| X52 (Main) | >359 MPa | Serving shale oil pipelines in Texas, onshore oil and gas gathering in Brazil, and cross-border gas transmission projects in Panama. |

| X60/X65 | >414/448 MPa | Transport of oil sands in Canada and medium to high-pressure oil pipelines in the Gulf of Mexico |

| X70/X80 | >483/552 MPa | U.S. cross-country oil pipelines, Brazilian deepwater oil and gas platforms. |

Technological Process

-

Raw Material Inspection – Select and inspect high-quality steel billets or coils.

-

Forming – Roll or pierce the material into pipe shape (Seamless / ERW / SAW).

-

Welding – Join pipe edges by electric resistance or submerged arc welding.

-

Heat Treatment – Improve strength and toughness through controlled heating.

-

Sizing & Straightening – Adjust pipe diameter and ensure dimensional accuracy.

-

Non-Destructive Testing (NDT) – Check for internal and surface defects.

-

Hydrostatic Test – Test each pipe for pressure resistance and leaks.

-

Surface Coating – Apply anti-corrosion coating (Black varnish, FBE, 3LPE, etc.).

-

Marking & Inspection – Mark specifications and perform final quality checks.

-

Packaging & Delivery – Bundle, cap, and ship with Mill Test Certificates.

Our Advantages

Local Branches & Spanish Support:

Our regional offices offer full Spanish-language assistance and manage customs procedures to ensure a smooth and hassle-free import process.

Reliable Inventory Availability:

We maintain strong stock levels so your orders can be processed and delivered without unnecessary delays.

Enhanced Protective Packaging:

Each pipe is securely wrapped and sealed to safeguard against damage, corrosion, and environmental exposure during transport.

Fast, Global Delivery:

We provide efficient worldwide shipping to keep your project timelines on track.

Packing and Transportation

Packaging:

Packaging detail: We deliver the API tubes on IPPC fumigated wooden pallets meeting the quarantine requirements of Central America. Triple-layered waterproof membrane, with plastic end caps - every bundle is fully covered. Bundles: 2–3 tons is typical and small cranes at local construction sites can usually handle the load.

Customization Options: The normal size is 12 m for containerized shipping. Suitable for transport overland in the mountainous regions of Guatemala, Honduras, and nearby locations are the short-length versions of 8 m and 10 m.

Full Documentation Set: The shipments are accompanied by the following consignment briefing documents: Spanish certificate of origin (form B); material certificate MTC; inspection report SGS; packing list and invoice commercial. Documentation mistakes can be corrected and reissued in 24 hours.

Transportation:

We offer standard transit estimates—China → Colón, Panama (30 days); Manzanillo, Mexico (28 days); Limón, Costa Rica (35 days)—and provide contacts for trusted local carriers (e.g., TMM in Panama) to handle last-mile delivery from the port to oil fields or construction sites.

FAQ

Q1: Do your API 5L pipes meet the standards in Americas?

A: Yes They are 100% compliant with API 5L 45th Edition, ASME B36.10M and local like Mexico NOM and Panama Free Trade Zone etc. All certifications (API, NACE MR0175, ISO 9001) can be verified online.

Q2: What steel grade should I select?

Low pressure (≤3 MPa): Grade B / X42 — city gas, irrigation.

Medium pressure (3–7 MPa): X52 — land oil and gas.

High pressure (≥7 MPa) / offshore: X65 / X70 / X80 — deepwater, high strength.

Tip: Our engineers are able to advise on the most suitable grade for your project needs.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506