ASTM A328 Gr 50 and JIS A5528 Sy295 Sy355 Sy390 Z Type Steel Sheet Pile

Product Detail

| Parameter | Specification / Range |

|---|---|

| Steel Grade | ASTM A328 Grade 50 JIS A5528 S295/S355/S390 |

| Standard | ASTM / JIS |

| Delivery Time | 10–20 Days |

| Certificates | ISO9001, ISO14001, ISO18001, CE FPC |

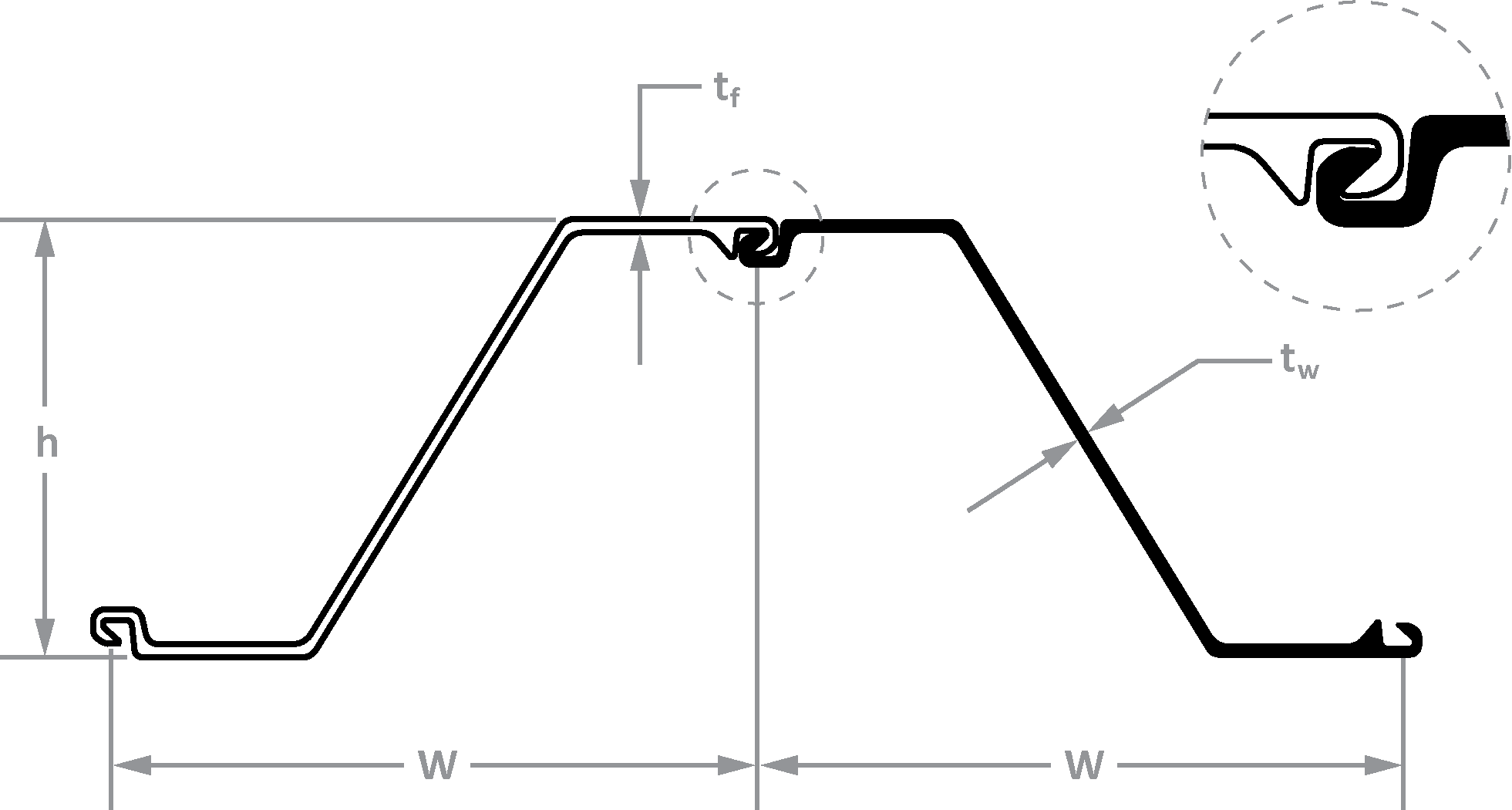

| Width | 400–750 mm (15.75–29.53 in) |

| Height | 100–225 mm (3.94–8.86 in) |

| Thickness | 9.4–23.5 mm (0.37–0.92 in) |

| Length | 6–24 m or custom lengths |

| Type | Z-type hot-rolled steel sheet pile |

| Processing Service | Cutting, Punching |

| Chemical Composition | C ≤0.22%, Mn ≤1.60%, P ≤0.035%, S ≤0.035% |

| Mechanical Properties | Yield strength ≥345 MPa (50 ksi); Tensile strength ≥450 MPa; Elongation ≥17% |

| Technique | Hot Rolled |

| Section Profiles | PZ400, PZ500, PZ600 series |

| Interlock Types | Larssen interlock, Hot-rolled interlock, Cold-rolled interlock |

| Applicable Standards | AISC Steel Design Standard |

| Applications | Port engineering, river & coastal protection, bridge foundations, retaining walls, deep excavation support |

ASTM A328 Gr 50 JIS A5528 Z Type Steel Sheet Pile Size

| JIS A5528 Model | ASTM A328 Corresponding Model | Effective Width (mm) | Effective Width (in) | Effective Height (mm) | Effective Height (in) | Web Thickness (mm) |

|---|---|---|---|---|---|---|

| PZ400×100 | ASTM A328 Type Z2 | 400 | 15.75 | 100 | 3.94 | 10.5 |

| PZ400×125 | ASTM A328 Type Z3 | 400 | 15.75 | 125 | 4.92 | 13 |

| PZ400×170 | ASTM A328 Type Z4 | 400 | 15.75 | 170 | 6.69 | 15.5 |

| PZ500×200 | ASTM A328 Type Z5 | 500 | 19.69 | 200 | 7.87 | 16.5 |

| PZ600×180 | ASTM A328 Type Z6 | 600 | 23.62 | 180 | 7.09 | 17.2 |

| PZ600×210 | ASTM A328 Type Z7 | 600 | 23.62 | 210 | 8.27 | 18 |

| PZ750×225 | ASTM A328 Type Z8 | 750 | 29.53 | 225 | 8.86 | 14.6 |

| Web Thickness (in) | Unit Weight (kg/m) | Unit Weight (lb/ft) | Material (Dual Standard) | Yield Strength (MPa) | Tensile Strength (MPa) | Americas Market Applications | Southeast Asia Market Applications |

|---|---|---|---|---|---|---|---|

| 0.41 | 50 | 33.5 | SY390 / Grade 50 | 390 | 540 | Used in small-scale municipal retaining structures across North America | Ideal for agricultural irrigation channels in the Philippines |

| 0.51 | 62 | 41.5 | SY390 / Grade 50 | 390 | 540 | Applied in general foundation stabilization across Midwestern regions | Suitable for drainage upgrades in Bangkok’s urban districts |

| 0.61 | 78 | 52.3 | SY390 / Grade 55 | 390 | 540 | Designed for levee reinforcement along the U.S. Gulf Coast | Used for compact-scale land reclamation works in Singapore |

| 0.71 | 108 | 72.5 | SY390 / Grade 60 | 390 | 540 | Effective for anti-seepage barriers in port areas such as Houston | Supports deep-water port construction in Jakarta |

| 0.43 | 78.5 | 52.7 | SY390 / Grade 55 | 390 | 540 | Commonly deployed for riverbank stabilization in California | Fits coastal industrial development protection needs in Ho Chi Minh City |

| 0.57 | 118 | 79 | SY390 / Grade 60 | 390 | 540 | Suitable for deep excavation and port infrastructure in Vancouver | Applied in major land reclamation expansions across Malaysia |

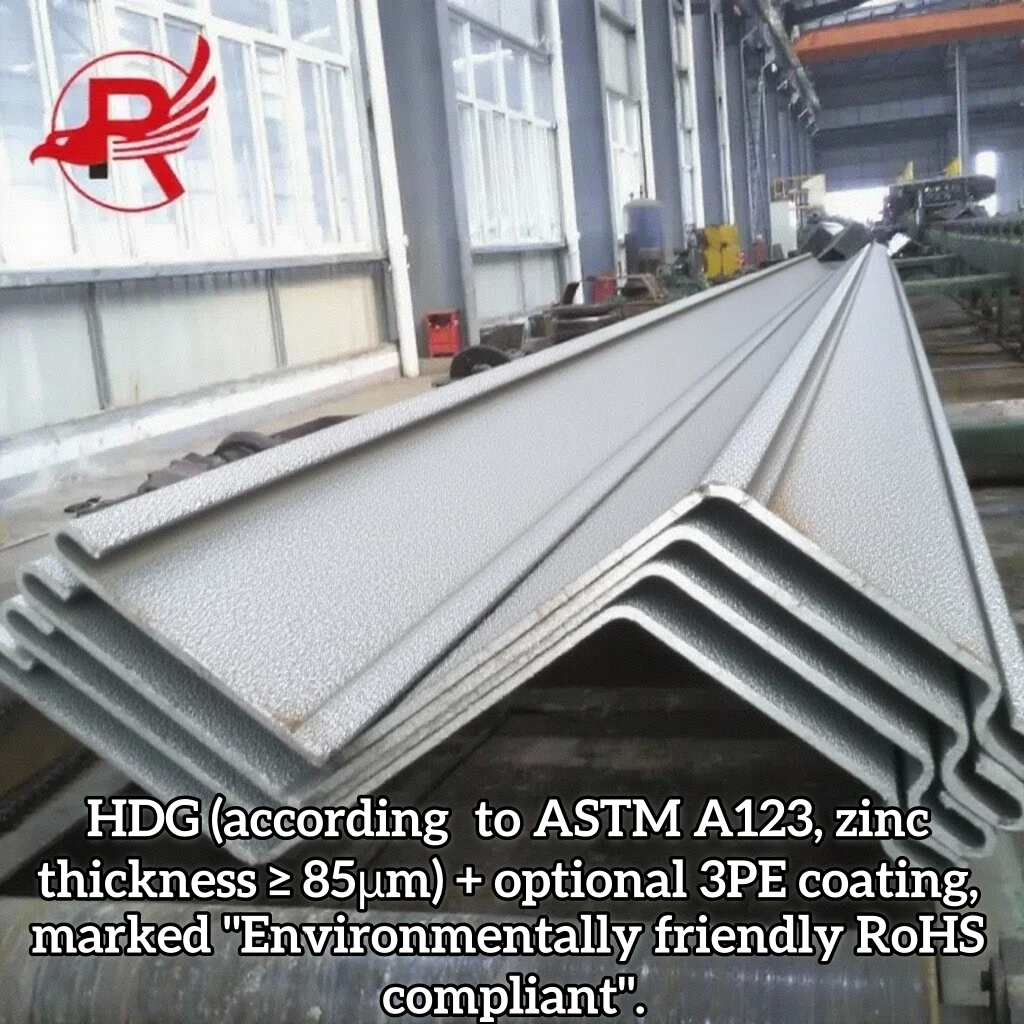

ASTM A328 Gr 50 JIS A5528 Z Type Steel Sheet Pile Corrosion prevention solution

Americas: HDG (according to ASTM A123, zinc thickness ≥ 85μm) + optional 3PE coating, marked "Environmentally friendly RoHS compliant".

Southeast Asia: Adopting a combined process of hot dip galvanizing (zinc layer thickness ≥ 100μm) and epoxy coal tar coating, its core advantage lies in no rusting even after 5,000 hours of salt spray testing, making it suitable for tropical marine climate environments.

ASTM A328 Gr 50 JIS A5528 Z Type Steel Sheet Pile Locking and waterproof performance

Design: Z-shape interlock, permeability ≤1×10⁻⁷cm/s

America: Meets the requirements of ASTM D5887, the standard test method for penetration of water through foundation and retaining walls.

Southeast Asia: High groundwater and flood-seepage resistance for tropical and monsoonal regions

ASTM A328 Gr 50 JIS A5528 Z Type Steel Sheet Pile Production Process

Steel Selection:

Select high-grade structural steel in accordance with specific mechanical performance requirements.

Heating:

Heat billets/slabs to ~1,200°C for malleability.

Hot Rolling:

Shape steel into Z-profile with rolling mills.

Cooling:

Cool down either naturally or via water spray until the target moisture content is achieved.

Straightening & Cutting:

Preserve tolerance precision while cutting the material to either standard or custom-specified lengths.

Quality Inspection:

Perform dimensional, mechanical, and visual inspections.

Surface Treatment (Optional):

If required, apply paint, galvanize or protect from rust.

Packaging & Shipping:

Pack, protect, and pick up for shipping.

ASTM A328 Gr 50 JIS A5528 Z Type Steel Sheet Pile Main Application

1. Port and Dock Revetment Engineering

2. River Management and Flood Control Embankments

3. Foundation Pit Support and Deep Foundation Engineering

4. Industrial and Water Conservancy Engineering

Our Advantages

1. Localized Support

2. Inventory Readiness

3. Professional Packaging Solutions

4. Reliable Logistics Services

5. Robust Logistics System

Packaging & Shipping

Steel Sheet Pile Packaging Details

Bundling & Securing: Steel sheet piles are neatly grouped into bundles, which are then fastened using either steel straps or plastic straps to ensure tight, stable bundling.

End Protection Measures: The end piles of each bundle are fitted with plastic caps or padded with wooden blocks—this prevents collision damage or wear to the pile ends during handling.

Anti-Rust Protection: To shield the sheet piles from rust, protective measures such as waterproof wrapping, rust-inhibiting oil coating, or plastic sheathing can be applied, depending on storage and transit needs.

Steel Sheet Pile Transportation

Loading Operations: Bundled sheet piles are loaded onto transport vehicles (trucks, flatbeds) or shipping containers using cranes or forklifts, ensuring efficient and safe lifting.

Transit Stability Control: During loading, the bundles must be stacked stably and further secured firmly. This prevents shifting, tilting, or collision between bundles during transportation.

On-Site Unloading: Upon arrival at the construction site, the sheet pile bundles are unloaded in an organized, sequential manner—this facilitates easy access and streamlined use in subsequent construction processes.

FAQ

Q: Do you serve the American market for steel sheet piles?

A: Yes, we provide top-quality steel sheet piles for the American market. With local offices across Latin America and a Spanish-speaking customer service team, we ensure smooth communication and premium support for your projects in the region.

Q: What are the packaging and delivery terms for steel sheet piles to the Americas?

A: Packaging: Professional bundling, protective end caps, and optional corrosion protection. Delivery: Safe logistics via truck, flatbed or container, with direct delivery to your job site.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506