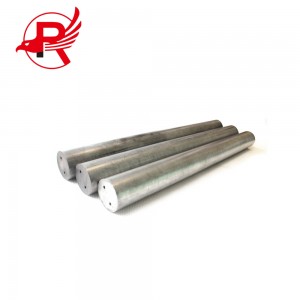

Hot Rolled Forged Mild GB Standard Carbon Steel Round/Square Iron Rod Bar Carbon Steel Rolled Forged Bars

The details of a carbon structure steel round bar typically include the dimensions. Carbon steel round bar is described by its diameter, length, and the grade of steel, which indicates its chemical composition and mechanical properties. Common grades are AISI 1018, 1045, and 1144. Good strength, good machinability, and good weldability make them popular in machining, manufacturing and construction. Surface finish, dimensional tolerances and standard compliance such as ASTM or SAE may also be needed.

PRODUCT PRODUCTION PROCESS

1. Raw Material Preparation

-

Material Selection: Choose high-quality steel free from scale, cracks, and major impurities.

-

Cutting: Cut into required lengths and diameters with smooth, defect-free ends.

2. Refining

-

Impurity Removal: Eliminate impurities through magnetic separation or manual sorting.

-

Preheating: Heat the material to the required temperature for further processing.

-

Refining Treatment: Use high-temperature refining to reduce carbon, sulfur, phosphorus, and adjust chemical composition.

3. Forming & Heat Treatment

Preforming: Shape the refined steel into bar form

Heat Treatment: Heat and hold at set temperatures to achieve desired mechanical properties.

Cooling: Air-cool naturally to stabilize the structure.

Finishing: The steel round bar is further subjected to fine processing such as wire cutting and polishing to achieve higher precision and surface quality.

PRODUCT SIZE

| Parameter | Specification / Details |

|---|---|

| Product Name | Steel Bar |

| Diameter | 2–500 mm |

| Length | 3000–6000 mm |

| Type | Round, Square, Hexagonal, Angle, Flat Bar |

| Surface Treatment | Cleaned, Blasting, Painting (per customer requirement) |

| Thickness Tolerance | ±0.1 mm |

| Material Options | 20#–50#, 16Mn–50Mn, 30Mn2–50Mn2, 20Cr, 40Cr, 20CrMnTi, 20CrMo, 15CrMo, 30CrMo, 35CrMo, 42CrMo, 42CrMo4, 60Si2Mn, 65Mn, 27SiMn, 20Mn, 40Mn2, 50Mn, 1Cr13, 2Cr13, 3Cr13, 4Cr13, Q195, Q235(A–D, R), Q345(B–D, R), Q345QC, Q345QD, SPCC, SPCD, SPCE, ST37, ST12, ST15, DC01–DC06 |

| Application | Small tools, components, iron wire, pull rods, ferrules, weld assemblies, structural metal, connecting rods, lifting hooks, bolts, nuts, spindles, axles, gears, chain wheels, car couplers |

| MOQ | 25 tons (sample orders accepted) |

| Shipment Time | 15–20 working days after deposit or TT/L/C |

| Export Packing | Waterproof paper + steel straps; standard seaworthy packing; suitable for all transport types |

| Annual Capacity | 250,000 tons/year |

| Usage Sectors | Shipbuilding, petrochemical, machinery, medicine, electricity, energy, architectural decoration, nuclear power, aerospace, seawater equipment, chemicals, pigments, papermaking, fertilizers, ropes, screws, nuts, etc. |

| Diameter (mm) | Section (cm²) | Unit Mass (kg/m) | Diameter (mm) | Section (cm²) | Unit Mass (kg/m) |

|---|---|---|---|---|---|

| 6 | 0.283 | 0.222 | 45 | 15.9 | 12.5 |

| 7 | 0.385 | 0.302 | 46 | 16.6 | 13.0 |

| 8 | 0.503 | 0.395 | 48 | 18.1 | 14.2 |

| 9 | 0.636 | 0.499 | 50 | 19.6 | 15.4 |

| 10 | 0.785 | 0.617 | 52 | 21.2 | 16.7 |

| 11 | 0.950 | 0.746 | 55 | 23.8 | 18.7 |

| 12 | 1.13 | 0.888 | 56 | 24.6 | 19.3 |

| 13 | 1.33 | 1.04 | 60 | 28.3 | 22.2 |

| 14 | 1.54 | 1.21 | 64 | 32.2 | 25.3 |

| 16 | 2.01 | 1.58 | 65 | 33.2 | 26.0 |

| 18 | 2.55 | 2.00 | 68 | 36.3 | 28.5 |

| 19 | 2.84 | 2.23 | 70 | 38.5 | 30.2 |

| 20 | 3.14 | 2.47 | 75 | 44.2 | 34.7 |

| 22 | 3.80 | 2.98 | 80 | 50.3 | 39.5 |

| 24 | 4.52 | 3.55 | 85 | 56.8 | 44.6 |

| 25 | 4.91 | 3.85 | 90 | 63.6 | 49.9 |

| 27 | 5.73 | 4.50 | 95 | 70.9 | 55.6 |

| 28 | 6.16 | 4.83 | 100 | 78.5 | 61.7 |

| 30 | 7.07 | 5.55 | 110 | 95.0 | 74.6 |

| 32 | 8.04 | 6.31 | 120 | 113 | 88.7 |

| 33 | 8.55 | 6.71 | 130 | 133 | 104 |

| 36 | 10.2 | 7.99 | 140 | 154 | 121 |

| 38 | 11.3 | 8.90 | 150 | 177 | 139 |

| 39 | 11.9 | 9.38 | 160 | 201 | 158 |

| 42 | 13.9 | 10.9 | 180 | 255 | 200 |

| – | – | – | 200 | 314 | 247 |

FEATURES

Hot rolled steel round bars are typically produced through a hot rolling process, where steel is heated above its recrystallization temperature and then passed through a series of rollers to achieve the desired shape. The main features of hot rolled steel round bars include:

Strength: Hot rolled round steel is known for its superior strength and durability, suitable for a wide array of industrial applications.

Ductility: Good ductility can be manufactured in a variety of products easily.

Surface Finish: The hot rolling process can produce a coarse surface finish, which can be brought out by rolling.

Versatility: Extremely popular in the building, tool and car industries because of its structural reliability.

Availability: Available in different sizes and grades to meet various application needs.

APPLICATION

Mild steel round bars have a wide range of applications due to their versatile properties. Some common applications include:

Construction: Reinforced concrete buildings, bridges and roads.

Manufacturing: Durable, easy to process and suitable for machine, equipment and component making.

Vehicle: Produce axles, shafts and vehicle structural components.

Farm Equipment: Used to manufacture tractors, plows and farming machinery.

General Fabrication: Used on gates, fences, frames and all manner of structural applications.

Home Hobby: Used for chairs, household products and small building projects.

Machining: Hand tools, machine tools, and plant equipment.

PACKAGING AND SHIPPING

Packing:

Stack bars careful and firm, stop bars moving by straping or lashing.

Wrap the bars in vapour tight material (plastic or waterproof paper) to stop rust and corrosion.

Traffic:

Select means of transportation following quantity, weight, distance and cost (flatbed, container, or ship).

Use the correct? lifting machinery (crane, forklift, loader) to handle safely.

Fasten your loads with straps or brackets so they don’t move while you’re driving.

COMPANY STRENGTH

Made in China - Premium quality and at cost effective service.

1.Scale favor: Large-scale integrated steel factory and supply chain guarantee the production & logistics efficiency.

2.Product Spectrum: Diversified product lines of steel structures, rails, sheet piles, PV brackets , channel steel , silicon steel coil.

3.Steady Supply: Massive productions and supply chain commitment.

4.Brand Authority: Established market and well-known brand.

5.One-stop Service: Customization, production and delivery service.

6.Affordable Quality: The Best Quality with the Most Reasonable Price.

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

FAQ

Q1: How to get a quotation?

A: Leave us a message and we will reply you as soon as possible.

Q2: Are you going to deliver in time?

A: Yes, we have high quality products and delivery on time. Our principle is honesty.

Q3: May I get samples prior to placed order?

A: Yes, samples are generally free. We can make according to your sample or technical drawing.

Q4: What are your payment terms?

A: Standard term: 30% deposit, balance against B/L. EXW, FOB, CFR,CIF is okay.

Q5: Will you accept the third party inspection?

A: Yes third party inspection is welcomed.

Q6: How can we trust your company?

A: We are experienced Golden Supplier for steel Industry for years, with headquarter in Tianjin. Welcome to check our company by any method you like.