ASTM A36 Steel Structure Agricultural Steel Structure

APPLICATION

Steel Residential Building:Exterior Designs' steel frame homes are well known for their high strength, light weight, fast installation, long life and good architectural design flexibilities.

Steel Structure House:Advantage of steel house building energy saving, environment friendliness, thermal insulation, short construction period.

Steel Structure Warehouse: Steel structure metal building warehouse with being large span, high space utilization, rapid installation, easy to design.

Steel Structure Factory Building: The load-bearing capacity of prefabricated steel structure is high, and the span can be large without any columns (this can be very good for workshop use).

Agricultural Steel Structure:Agricultural steel buildings are a steel-framed system with superior components and designs used primarily for farm buildings, barns, horses stables, poultry or pig houses, greenhouses, and more.

PRODUCT DETAIL

Core steel structure products for factory construction

1. Main load-bearing structure (adaptable to tropical seismic requirements)

| Product Type | Specification Range | Core Function | Central America Adaptation Points |

| Portal Frame Beam | W12×30 ~ W16×45 (ASTM A572 Gr.50) | Main beam for roof/wall load-bearing | Seismic node designed for (bolted connections not brittle welds), section optimized to minimize self weight for local transport. |

| Steel Column | H300×300 ~ H500×500 (ASTM A36) | Supports frame and floor loads | Seismic connectors embedded in the base, galvanized surface (zinc coating = 85μm) for corrosion resistance in high humidity environments. |

| Crane Beam | W24×76 ~ W30×99 (ASTM A572 Gr.60) | Load-bearing for industrial crane operation | Robust design (for 5~20t cranes), end beam connected with shear-resistant plates. |

2. Enclosure system products (weatherproof + anti-corrosion)

Roof purlins: C12×20~C16×31 (hot-dip galvanized), spaced 1.5~2m apart, suitable for color-coated steel plate installation, and resistant to typhoon loads up to level 12.

Wall purlins: Z10×20~Z14×26 (anti-corrosion painted), with ventilation holes to reduce humidity in tropical factories.

Support system: Bracing (Φ12~Φ16 hot-dip galvanized round steel) and corner braces (L50×5 steel angles) enhance the structure's lateral resistance to withstand hurricane-force winds.

3. Supporting auxiliary products (localized construction adaptation)

1.Embedded hardware 10mm 20mm steel plate hot dip galvanised, for concrete foundations used in central america.

2.Connectors: Grade 8.8 high-strength bolt with hot-dip galvanization, which can be assembled without welding in site, greatly shortening the construction period.

3.Japanese Good quality water-based flame-retardant paint with fire resistivity ≥1.5h + Acrylic anti-corrosive paint with UV-protection, validity period >10 years, fulfilling local environmental protection standards.

STEEL STRUCTURE PROCESSING

| Processing Method | Machines/Equipment | Processing Description |

|---|---|---|

| Cutting | CNC Plasma/Flame Cutters, Shears | CNC plasma/flame cutting for steel plates and sections; shearing for thin steel plates with dimensional accuracy control. |

| Forming | Cold Bending Machine, Press Brake, Rolling Machine | Cold bending for C/Z purlins, bending for gutters/edges, rolling for round support bars. |

| Welding | Submerged Arc Welding (SAW), Manual Arc Welder (MMA), CO₂ Gas-Shielded Welder (MIG/MAG) | SAW for H-shaped columns and beams, MMA for gusset plates, CO₂ welding for thin-walled parts. |

| Holemaking | CNC Drilling Machine, Punching Machine | CNC drilling for bolt holes in connecting plates/components; punching for small batches with controlled hole size and position. |

| Surface Treatment | Shot/Sand Blasting Machine, Grinder, Hot-Dip Galvanizing Line | Rust removal by shot/sand blasting, weld grinding for deburring, hot-dip galvanizing for bolts and supports. |

| Assembly | Assembly Platform, Measuring Fixtures | Pre-assembly of columns, beams, and supports; disassembly after dimensional checks for shipping. |

STEEL STRUCTURE TESTING

| 1. Salt spray test (core corrosion test) Using ASTM B117 and ISO 11997-1 standards, this test evaluates coating corrosion resistance under high-salt conditions, such as coastal environments. |

2. Adhesion test Two methods are used: the ASTM D3359 cross-cut test to assess coating adhesion, and the ASTM D4541 pull-off test to measure bond strength. |

3. Humidity and heat resistance test ASTM D2247 (40°C/95% RH to prevent blistering and peeling of coating in rainy seasons). |

| 4. UV aging test ASTM G154 (to simulate a high UV level in rainforests, to inhibit color fading and chalking of the paint). |

5. Film thickness test Dry film thickness is measured per ASTM D7091 using a magnetic gauge, and wet film thickness per ASTM D1212 to ensure proper coating buildup. |

6. Impact strength test Standards ASTM D2794 (drop-hammer impact, protect from damage in shipping/handling. and installation). |

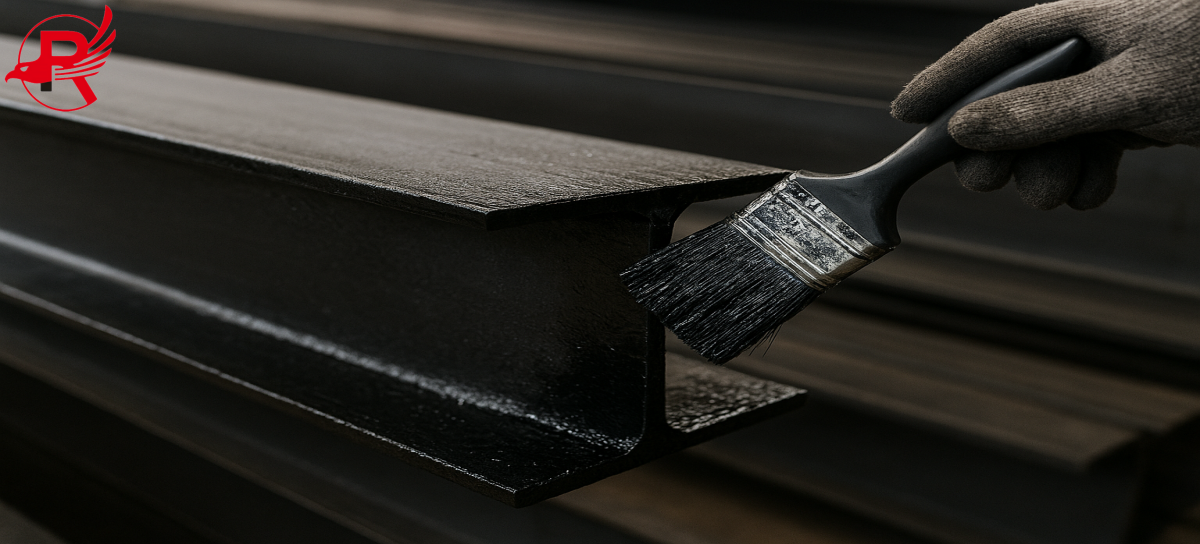

SURFACE TREATMENT

Surface Treatment Display: Epoxy zinc-rich coating, galvanized (hot dip galvanized layer thickness ≥85μm service life can reach 15-20 years), black oiled, etc.

Black Oiled

Galvanized

Epoxy Zinc-rich Coating

PACKAGING AND SHIPPING

Packaging:

In order to prevent steel structure parts from being hurt in the process of handling and transportation, those parts are high-packed and an extra protective layer is added among them to prevent wear by friction or impact. The large components, sub-assemblies and main packages are completely wrapped in waterproof materials (plastic film, rustproof paper etc.) for moisture and rust protection, the small items are placed in wooden boxes to avoid loss or damage. Each kit and component part thereof has a unique label including component information and installation location details, ensuring that they can be safely unloaded on site and that you can install each on site efficiently.

Transportation:

Static steel may be delivered in containers or bulk carriers by size and destination. Strapping is commonly used to secure large or heavy items, and these items are strapped with steel straps protected by wood on either side to prevent movement and damage during transportation. For logistics, everything is arranged with the international transport standard for long distance shipping, even international shipping, delivering on time and safe arrival.

OUR ADVANTAGES

1.Overseas Branches & Support in Spanish

The teams in our international offices who speak Spanish support our Latin American clientele, as well as those in Europe, in all facets of communication, customs and documentation assistance, and the logistics coordination needed to execute the job efficiently and quickly.

2.Ready Stock for Fast Delivery

Sufficient stocks of H beams, I beams and steel elements make quick turnaround and prompt delivery possible for emergencies.

3Professional Packaging

Sea shipment packaging: wood packing+steel bundling+waterproof wrapping+edge protection can make products transported safely without any damage.

4.Efficient Shipping & Delivery

Various delivery methods (FOB, CIF, DDP) can be chosen and excellent shipping lines have been cooperated with guarantee that your cargo could flow smoothly with no delay.

FAQ

Regarding Material Quality

Q: What are your steel structure quality standards?

A: Our steel structure meets the american standards such as ASTM A36,ASTM A572. ASTM A36 is the most widely used carbon structural steel, while A588 is a high strength, low alloy, heat resistant structural steel used in severe atmospheric conditions.

Q: What makes sure for the quality of steel materials?

A: We purchase steel from well-known domestic/international steel corporation, who have quality assurance system. All steel products are tested rigorously such as analysis of chemical composition, testing of mechanical properties and non-destructive testing (UT, MPT) to comply with related standards.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506