SAW for H-Beams/Columns, MMA for Gusset Plates & CO₂ Welding for Thin Parts

ASTM A36 Steel Structure Industrial Building Structure

APPLICATION

Steel Structure Building: Steel structures are supported by high strength steel, which brings the great advantages of being earthquake-proof, wind-proof, speedy in construction and flexible in space.

Steel Structure House: Steel frame house can be saved energy, environmental protection, thermal insulation, and the shortest time of investment for that it use the construction of lightweight steel frame.

Steel Structure Warehouse: Steel structure warehouse has characteristics of large spans, high space utilization, fast installation and flexible design.

Steel Structure Industrial Building:Steel structure industrial buildings are strong, lightweight, and ideal for fast, large-span construction.

PRODUCT DETAIL

Core steel structure products for factory construction

1. Main load-bearing structure (adaptable to tropical seismic requirements)

| Product Type | Specification Range | Core Function | Central America Adaptation Points |

| Portal Frame Beam | W12×30 ~ W16×45 (ASTM A572 Gr.50) | Main beam for roof/wall load-bearing | The design for the high-seismic node consists of bolted flanges which avoids brittle welds, and the optimized sections reduce the self-weight to ease the local transport. |

| Steel Column | H300×300 ~ H500×500 (ASTM A36) | Supports frame and floor loads | Sismic base plate connectors embedded, Hot-dip galvanized (Zinc coating ≥ 85μm) to resist corrosion in high humidity environment. |

| Crane Beam | W24×76 ~ W30×99 (ASTM A572 Gr.60) | Load-bearing for industrial crane operation | Heavy-duty construction (cranes 5–20t) with end beams fitted with connection plates that are shear resistant. |

2. Enclosure system products (weatherproof + anti-corrosion)

Roof Purlins: C12×20–C16×31 (hot-dip galvanized) with 1.5–2m centers is suitable for color-coated steel sheet installation and can resist typhoon load up to level 12.

Wall Purlins: Z10×20-Z14×26 (anti-corrosion painted) with ventilation holes to minimize dampness in tropical factory conditions.

Support System: Bracing (Φ12–Φ16 hot-dip galvanized round steel) and corner braces (L50×5 steel angles) increase lateral rigidity and guarantee good performance in winds of hurricane strength.

3. Supporting auxiliary products (localized construction adaptation)

1.Partes empotradas Placas de acero galvanizado de 10 ‑20 mm adaptadas a bases de concreto corrientes en Centro América.

2.Braids: Grade 8.8 hot-dip galvanized bolts no on-site welding needed, saving assembly time.

3.Revestimientos: Pintura hidrosoluble ignífuga (≥1,5 h) y pintura acrílica protectora anti-corrosiva (vida útil ≥10 años), conforme a normativas medioambientales.

STEEL STRUCTURE PROCESSING

| Processing Method | Processing Machines | Processing |

| Cutting | CNC Cutting & Shearing Machines | CNC Plasma/Flame Cutting & Shearing for Steel with Accurate Dimensions |

| Forming | Bending & Rolling Machines | Cold Bending, Bending & Rolling for Steel Profiles |

| Welding | Submerged Arc, Manual & CO₂ Gas-Shielded Welders |

|

| Holemaking | CNC Drilling & Punching Machines | CNC Drilling & Punching for Accurate Bolt Holes |

| Treatment | Surface Treatment & Finishing Equipment | Shot/Sand Blasting, Weld Grinding & Hot-Dip Galvanizing for Steel Components |

| Assembly | Assembly Platforms & Measuring Fixtures | Pre-Assemble Columns, Beams & Supports, Then Disassemble for Shipping |

STEEL STRUCTURE TESTING

| 1. Salt spray test (core corrosion test) Meets ASTM B117 and ISO 11997-1 salt spray standards, ideal for Central America’s coastal environment. |

2. Adhesion test Crosshatch test (ASTM D3359) for coating adhesion, pull-off test (ASTM D4541) for peel strength. |

3. Humidity and heat resistance test Conforms to ASTM D2247 (40°C/95%RH) to avoid blistering and cracking of the coating during rainy weather. |

| 4. UV aging test Complies with ASTM G154 to protect against UV caused color fading and chalking under the exposure of the rain forest. |

5. Film thickness test Dry film thickness was measured by ASTM D7091 and wet film thickness by ASTM D1212 to achieve the required corrosion-resistant thickness. |

6. Impact strength test Complies with ASTM D2794 (drop hammer impact) to safeguard against harm in the course of shipping and handling. |

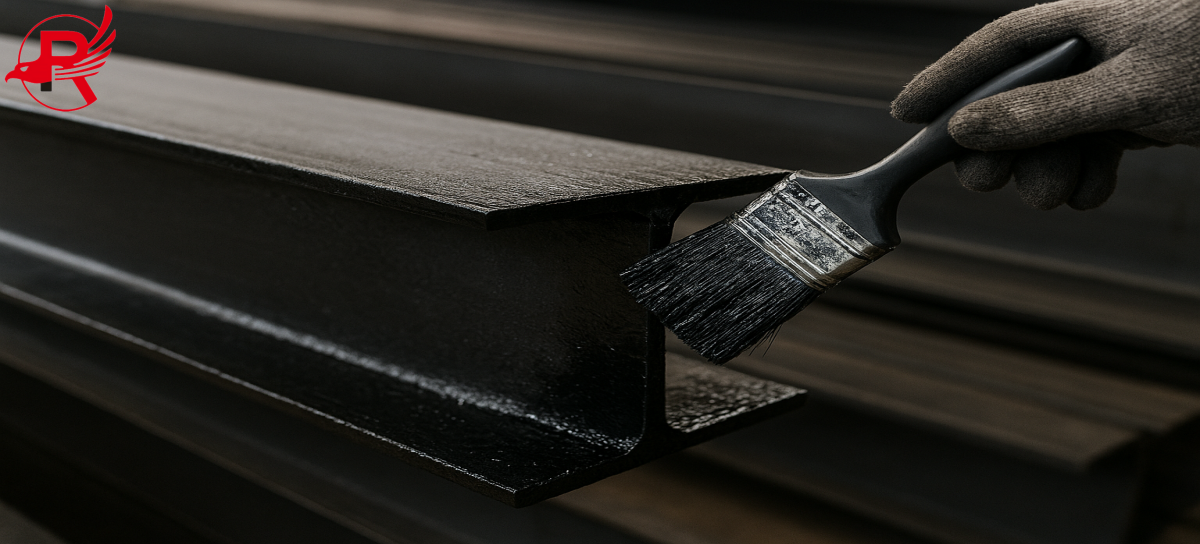

SURFACE TREATMENT

Surface Treatment Display: Epoxy zinc-rich coating, galvanized (hot dip galvanized layer thickness ≥85μm service life can reach 15-20 years), black oiled, etc.

Black Oiled

Galvanized

Epoxy Zinc-rich Coating

PACKAGING AND SHIPPING

Packaging:

The surface of the steel is protected and handling and shipping is safe by the well packaging of the steel construction. The big parts are wrapped with water proof materials such as plastic film or rust proof paper etc, the small parts are packed in wooden boxes. Each bale or section is clearly marked to facilitate off-loading and accurate assembly at site.

Transportation:

Steel structures may be sent by container or by bulk vessel according to size and destination. Large, heavy pieces are then crated and strapped with steel bands and wooden edge protectors so they don’t move and get damaged. All logistics are in compliance with international transport standard for safe and timely delivery even for long distance or international trip.

OUR ADVANTAGES

1.Overseas Branches & Spanish Support

Spanish-speaking teams at our overseas branches assist Latin American and European clients with communication, customs clearance, documentation, and logistics for smooth, fast delivery.

2.Ready Stock for Fast Delivery

We keep ample inventory of H beams, I beams, and steel components, ensuring short lead times and prompt supply for urgent projects.

3.Professional Packaging

Products are packed with seaworthy standards — steel bundling, waterproof wrapping, and edge protection — ensuring safe, damage-free transport.

4.Efficient Shipping & Delivery

Flexible delivery options (FOB, CIF, DDP) with reliable shipping partners guarantee on-time shipment and easy logistics tracking.

FAQ

Regarding Material Quality

Q: What are your steel structure standards?

A: The steel structure is with American standard ASTM A36 and ASTM A572. (ASTM A36 is a general purpose carbon structural steel A588 is a high-weather resistance steel for use in severe atmospheric environments).

Q: How do you control steel quality?

A: We buy from well-known and trusted mills in the US and internationally that have rigorous quality assurance programs. All materials are subjected to intensive testing on arrival including chemical composition determination, mechanical properties testing and non-destructive testing such as UT and MPT and that they conform to the related standards.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506