ASTM A36 Steel Structure School Building Steel Structure

APPLICATION

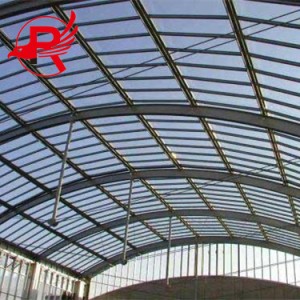

Steel Structure Building: The steel structure is supported by high-strength steel, and it has the characteristics of strong resistance to earthquake and wind, short construction period and flexible space.

Steel Structure House: Steel structures utilize lightweight steel framing, offering energy conservation, environmental protection, thermal insulation, and a short construction period.

Steel Structure Warehouse:The dent steel building has advantages of large span, high space utilization, fast construction and convenient shelf placement.

Steel Structure Factory Building: Our steel fram factory buildings are strong and are available in wide spans allowing for column free interiors, suitable for production and industrial use.

PRODUCT DETAIL

Core steel structure products for factory construction

1. Main load-bearing structure (adaptable to tropical seismic requirements)

| Product Type | Specification Range | Core Function | Central America Adaptation Points |

| Portal Frame Beam | W12×30 ~ W16×45 (ASTM A572 Gr.50) | Main beam for roof/wall load-bearing | Seismic design for high-acceleration node (bolted connections to avoid brittle welds), section optimized to reduce the self-weight to ease local transport. |

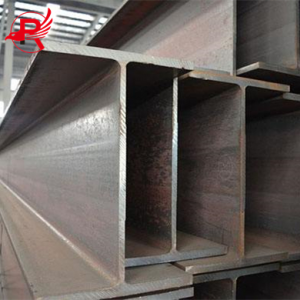

| Steel Column | H300×300 ~ H500×500 (ASTM A36) | Supports frame and floor loads | Ground-embedded seismic connectors, hot-dip galvanized (zinc coating ≥85μm) for protection against high humidity environment |

| Crane Beam | W24×76 ~ W30×99 (ASTM A572 Gr.60) | Load-bearing for industrial crane operation | Heavy-duty construction (ideal for 5~20t cranes), end beam fitted with shear-resistant connecting plates. |

2. Enclosure system products (weatherproof + anti-corrosion)

Roof purlins: C12×20~C16×31 (hot-dip galvanized), spaced 1.5~2m apart, suitable for color-coated steel plate installation, and resistant to typhoon loads up to level 12.

Wall purlins: Z10×20~Z14×26 (anti-corrosion painted), with ventilation holes to reduce humidity in tropical factories.

Support system: Diagonal bracing (hot-dip galvanized round steel Φ12~Φ16) and corner braces (steel angles L50×5) are used to increase the lateral stability of the frame to resist hurricane force winds.

3. Supporting auxiliary products (localized construction adaptation)

1.Embedded parts: Steel plate embed ded parts (10mm-20mm thick, hot-dip galvanized), applicable for concrete foundation in general for use in Central America;

2.Connectors: High strength bolts (grade 8.8, hot dip galvanised) no on site welding is required and the construction time is reduced;

3.Fire Retardant & Anti Corrosive Material: Water-borne fire retardant paint (fire resistance ≥1.5h) and acrylic anti-corrosive paint (UV proof, life time ≥10 years) meeting the local environmental protect application.

STEEL STRUCTURE PROCESSING

| Processing Method | Processing Machines | Processing Description |

|---|---|---|

| Cutting | CNC plasma/flame cutting machines, shearing machines | CNC plasma/flame cutting for steel plates and sections; shearing for thin plates with controlled dimensional tolerances. |

| Forming | Cold bending machine, press brake, rolling machine | Cold bending for C/Z purlins, bending for gutters and edge trims, rolling for round support bars. |

| Welding | Submerged arc welder, manual arc welder, CO₂ gas-shielded welder | SAW for H-columns and beams, manual welding for gusset plates, and CO₂ welding for thin-walled components. |

| Holemaking | CNC drilling machine, punching machine | CNC drilling for bolt holes in connecting plates/components; punching for small-batch holes with controlled diameter and positioning accuracy. |

| Surface Treatment | Shot blasting/sand blasting machine, grinder, hot-dip galvanizing line | Rust removal by shot/sand blasting, weld grinding for deburring, hot-dip galvanizing for bolts and structural supports. |

| Assembly | Assembly platform, measuring fixtures | Pre-assembly of columns, beams, and supports; disassembled after dimensional verification for shipment. |

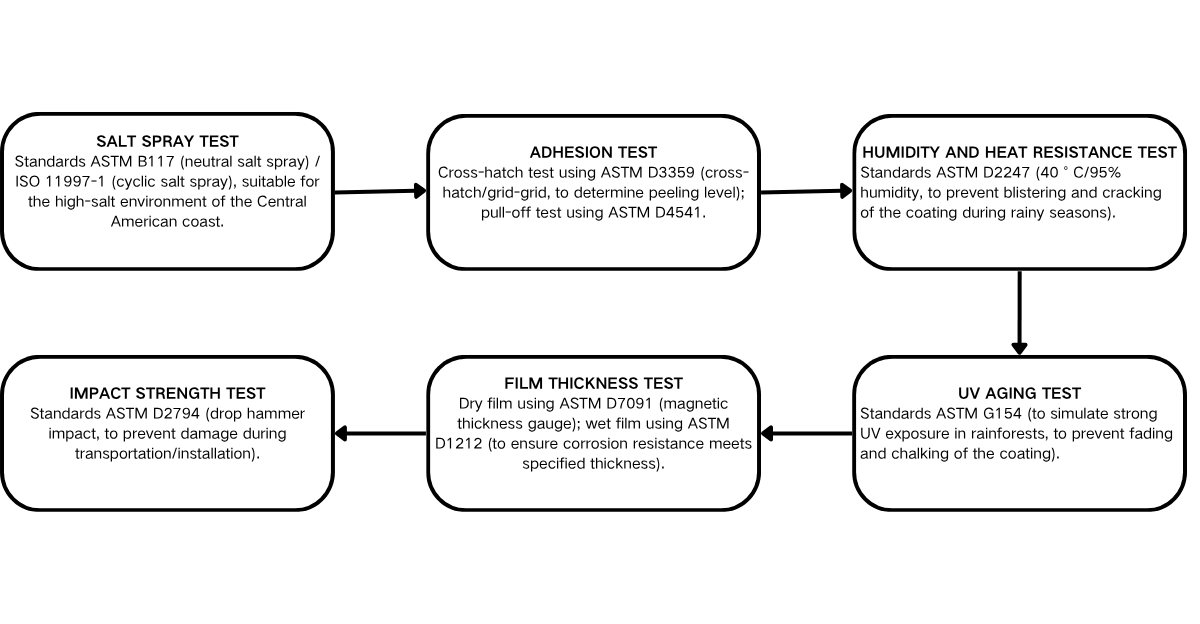

STEEL STRUCTURE TESTING

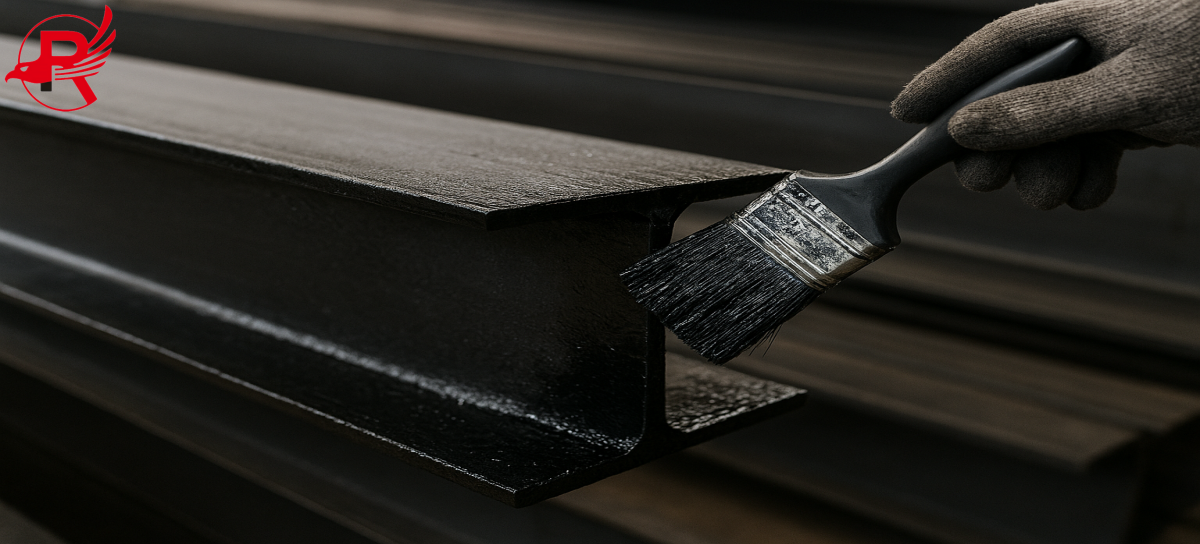

SURFACE TREATMENT

Surface Treatment Display: Epoxy zinc-rich coating, galvanized (hot dip galvanized layer thickness ≥85μm service life can reach 15-20 years), black oiled, etc.

BLACK OILED

GALVANIZED

Epoxy Zinc-rich Coating

PACKAGING AND SHIPPING

Packaging:

The steel is tightly packed to shield the surface and keep the Stiffness during the handling and transportation. The products are usually wrapped with waterproof material, plastic wrapping or rust proof paper and the small accessories are packed in wooden boxes. All bales/panels are well labeled to differentiate them, which also would facilitate safe and efficient unloading and installation at site.

Transportation:

The steel building components are shipped by container or bulk vessel according to size and destination. Heavy or large components are securely crated using steel strapping and wood blocking to prevent movement or damage during transit. All our logistics conform to the requirements of international transportation, so we could promise delivery on time, and also keep the safety even under long distance or ocean going vessel.

OUR ADVANTAGES

1. Overseas Branches & Spanish Support

Spanish-speaking teams assist Latin American and European clients with communication, customs, documents, and logistics for smooth delivery.

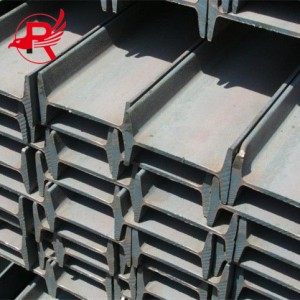

2. Ready Stock for Fast Delivery

Large inventories of H beams, I beams, and structural parts ensure short lead times and quick supply for urgent projects.

3. Professional Packaging

Seaworthy packaging with steel bundling, waterproof wrapping, and edge protection guarantees safe, damage-free transport.

4. Efficient Shipping & Delivery

Reliable shipping partners and flexible terms (FOB, CIF, DDP) provide on-time delivery and efficient tracking by sea or rail.

FAQ

Regarding Structural Design and Safety

Q: Can your steel structure meet the seismic requirements in the Americas?

A: Yes, our steel structure design takes into account the seismic characteristics of different regions in the Americas.

We adopt high - seismic - resistant node designs, such as bolt - connected joints, which can effectively absorb seismic energy and avoid brittle fracture of welds during earthquakes.At the same time, we will conduct seismic calculations according to local seismic intensity requirements to ensure that the steel structure has sufficient seismic performance.

Q: How do you ensure the overall stability of the steel structure?

A: Our steel structure design is based on strict mechanical calculations and engineering experience. We reasonably arrange the main load - bearing structures, such as portal frames, columns, and crane beams, and set up a complete support system, including tie bars and corner braces, to enhance the lateral stability of the structure and ensure that the steel structure can safely bear various loads under normal use and extreme conditions.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506