The H-beams and columns are submerged arc welded, the gusset plate is arc welded manually and the thin walled sections are welded with co2 gas.

ASTM A36 Steel Structure Shopping Malls & Exhibition Centers Structure

APPLICATION

Steel structure Hotel:Shopping malls and exhibition centers use steel structures for large, open spaces, flexible layouts, and fast construction.

Steel Structure School: Steel frame house can be saved energy, environmental protection, thermal insulation, and the shortest time of investment for that it use the construction of lightweight steel frame.

Steel Structure Warehouse: Steel structure warehouse has characteristics of large spans, high space utilization, fast installation and flexible design.

Steel Structure Industrial Building:Steel structure industrial buildings are strong, lightweight, and ideal for fast, large-span construction.

PRODUCT DETAIL

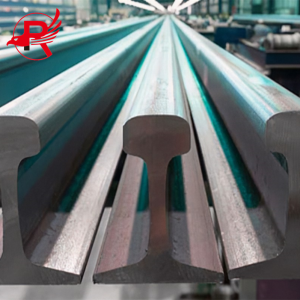

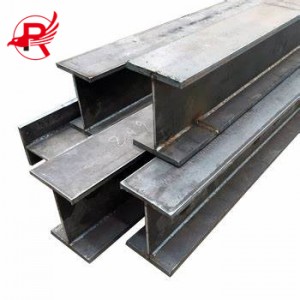

Core steel structure products for factory construction

1. Main load-bearing structure (adaptable to tropical seismic requirements)

| Product Type | Specification Range | Core Function | Central America Adaptation Points |

| Portal Frame Beam | W12×30 ~ W16×45 (ASTM A572 Gr.50) | Main beam for roof/wall load-bearing | The high seismic nodes employ bolted flanges to prevent brittleness in welds and have been structurally optimized to minimize the weight for ease of transport. |

| Steel Column | H300×300 ~ H500×500 (ASTM A36) | Supports frame and floor loads | The seismic base plate connectors are hot-dip galvanized (≥85 μm) to provide the minimum corrosion protection for use in moist environment. |

| Crane Beam | W24×76 ~ W30×99 (ASTM A572 Gr.60) | Load-bearing for industrial crane operation | Robust construction (5–20t cranes) with end beams with shear-resistant connection plates. |

2. Enclosure system products (weatherproof + anti-corrosion)

Roof Purlins: C12×20–C16×31 (hot-dip galvanized) with 1.5–2m centers is suitable for color-coated steel sheet installation and can resist typhoon load up to level 12.

Wall Purlins: Z10×20-Z14×26 (anti-corrosion painted) with ventilation holes to minimize dampness in tropical factory conditions.

Support System: Bracing (Φ12–Φ16 hot-dip galvanized round steel) and corner braces (L50×5 steel angles) increase lateral rigidity and guarantee good performance in winds of hurricane strength.

3. Supporting auxiliary products (localized construction adaptation)

1.Partes incrustadas: placas de acero galvanizado de 10 a 20 mm, se adapta a cimentaciones de concreto conocidad en Centroamérica.

2.Conectores: Pernos de alta resistencia grado 8.8, galvanizados en caliente, no es necesario soldar en el sitio, facilitando el montaje.

3.Revestimientos: Pintura ignífuga a base de agua (≥1,5 h) y pintura acrílica anti-corrosiva con protección UV (vida útil ≥ 10 años), en cumplimiento con las normativas ambientales locales.

STEEL STRUCTURE PROCESSING

| Processing Method | Processing Machines | Processing |

| Cutting | CNC plasma/flame cutting machine, shearing machine | Plasmas / flame cutting( steel plates / sections), shearing( thin steel plates), with controlled dimensional accuracy |

| Forming | Cooling bending machine, press brake machine, rolling machine. | Cold bending (for C/Z purlins), folding (for gutters/edge trimming), rolling (for round support bars) |

| Welding | Submerged arc welding machine, manual arc welder, CO₂ gas-shielded welder |

|

| Holemaking | CNC driller, puncher machine. | CNC drilled for bolt holes and punched for short runs, guaranteeing hole size and loca |

| Treatment | Shot blasting/sand blasting machine, grinder, hot-dip galvanizing line | Removal of rust (shot blasting/sand blasting), weld grinding (for deburring), hot-dip galvanizing (for bolts/supports) |

| Assembly | Assembly station, inspection fixture | Pre-fabricate components (columns + beams + supports), dismount after dimensional check for shipping |

STEEL STRUCTURE TESTING

| 1. Salt spray test (core corrosion test) Meets ASTM B117 and ISO 11997-1 salt spray standards, ideal for Central America’s coastal environment. |

2. Adhesion test Crosshatch test (ASTM D3359) for coating adhesion, pull-off test (ASTM D4541) for peel strength. |

3. Humidity and heat resistance test Conforms to ASTM D2247 (40°C/95%RH) to avoid blistering and cracking of the coating during rainy weather. |

| 4. UV aging test Complies with ASTM G154 to protect against UV caused color fading and chalking under the exposure of the rain forest. |

5. Film thickness test Dry film thickness was measured by ASTM D7091 and wet film thickness by ASTM D1212 to achieve the required corrosion-resistant thickness. |

6. Impact strength test Complies with ASTM D2794 (drop hammer impact) to safeguard against harm in the course of shipping and handling. |

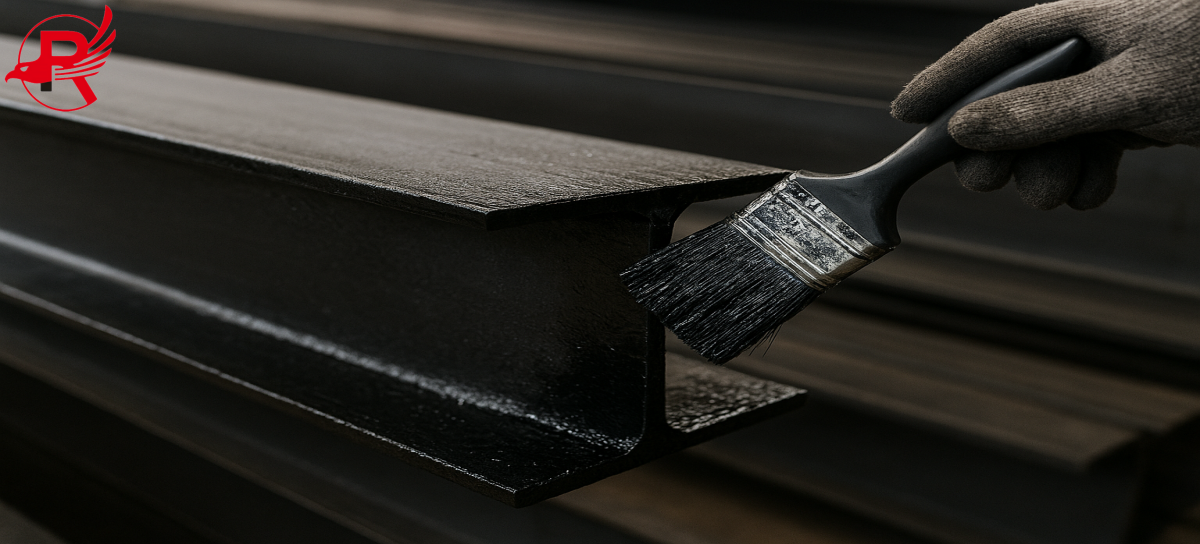

SURFACE TREATMENT

Surface Treatment Display: Epoxy zinc rich coating, galvanized (hot dip galvanized layer thickness≥85μm service life can be 15-20 years), blacflowyiled, etc.

Black Oiled

Galvanized

Epoxy Zinc-rich Coating

PACKAGING AND SHIPPING

Packaging:

Steel framework is securely packaged to ensure safe handling and shipping. Large pieces are wrapped with a waterproof material and small pieces are packed in wooden boxes and each box is clearly labeled for easy unloading and assembly.

Transportation:

Steel construction can be transported in containers or by the bulk vessel, with big objects tied with steel straps and wooden blocks based on international standards for delivery assurance and on time.

OUR ADVANTAGES

1. Overseas Branch & Spanish Language Support

We have overseas branches with Spanish-speaking teams to provide full communication support for Latin American and European clients.

Our team assists with customs clearance, documentation, and logistics coordination, ensuring smooth delivery and faster import procedures.

2. Ready Stock for Fast Delivery

We maintain sufficient inventory of standard steel structure materials, including H beams, I beams, and structural components.

This enables shorter lead times, ensuring customers receive products quickly and reliably for urgent projects.

3.Professional Packaging

All products are packed with standard seaworthy packaging — steel frame bundling, waterproof wrapping, and edge protection.

This ensures safe loading, long-distance transport stability, and damage-free arrival at the destination port.

4.Efficient Shipping & Delivery

We work closely with reliable shipping partners and provide flexible delivery terms such as FOB, CIF, and DDP.

Whether by sea, rail, we guarantee on-time shipment and efficient logistics tracking services.

FAQ

Regarding Material Quality

Q:What are the quality standards of your steel structure?

A: Our steel structure complies with American standard such as ASTM A36,ASTM A572. ASTM A36 is a normal carbon structural steel, and A588 is high weather-resistant structural steel for severe atmospheric environment.

Q:How do you check the quality of steel?

A: We purchase with quality in mind and work with mills that have proven quality and a good track record. Every material is subject to a full inspection at the time of delivery, such as: chemical analysis inspection, mechanical properties inspection, observation through non-destructive testing radiography, ultrasonic testing, magnetic particle testing, visual inspection complies to whatever standards needed.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506