ASTM A36/A992/A992M/A572 Gr 50 Steel I Beam

| Material Standard | ASTM A992/A992M standard (preferred for construction) or ASTM A36 standard (general structural) | Yield Strength | A992: Yield strength ≥ 345 MPa (50 ksi), tensile strength ≥ 450 MPa (65 ksi), elongation ≥ 18% A36: Yield strength ≥ 250 MPa (36 ksi), tensile strength ≥ 420 MPa A572 Gr.50: Yield strength ≥ 345 MPa, suitable for heavy-duty structures |

| Dimensions | W8×21 to W24×104 (inches) | Length | Stock for 6 m & 12 m, Customized Length |

| Dimensional Tolerance | Conforms to GB/T 11263 or ASTM A6 | Quality Certification | EN 10204 3.1 material certification & SGS/BV third-party testing report (tensile and bending tests) |

| Surface Finish | Hot-dip galvanizing, paint, etc. Customizable | Applications | Building Construction,Bridges,Industrial Structures,Marine and Transportation,Miscellaneous |

| Carbon Equivalent | Ceq≤0.45%(Ensure good weldability) Explicitly labeled "Compatible with AWS D1.1 welding code" |

Surface quality | No visible cracks, scars, or folds. Surface flatness: ≤2mm/m Edge perpendicularity: ≤1° |

| Property | ASTM A992 | ASTM A36 | Advantage / Notes |

| Yield Strength | 50 ksi / 345 MPa | 36 ksi / 250 MPa | A992: +39% higher |

| Tensile Strength | 65 ksi / 450 MPa | 58 ksi / 400 MPa | A992: +12% higher |

| Elongation | 18% (200 mm gauge) | 21% (50 mm gauge) | A36: better ductility |

| Weldability | Excellent (Ceq <0.45%) | Good | Both suitable for structural welding |

| Shape | Depth (in) | Flange Width (in) | Web Thickness (in) | Flange Thickness (in) | Weight (lb/ft) |

| W8×21(Sizes Available) | 8.06 | 8.03 | 0.23 | 0.36 | 21 |

| W8×24 | 8.06 | 8.03 | 0.26 | 0.44 | 24 |

| W10×26 | 10.02 | 6.75 | 0.23 | 0.38 | 26 |

| W10×30 | 10.05 | 6.75 | 0.28 | 0.44 | 30 |

| W12×35 | 12 | 8 | 0.26 | 0.44 | 35 |

| W12×40 | 12 | 8 | 0.3 | 0.5 | 40 |

| W14×43 | 14.02 | 10.02 | 0.26 | 0.44 | 43 |

| W14×48 | 14.02 | 10.03 | 0.3 | 0.5 | 48 |

| W16×50 | 16 | 10.03 | 0.28 | 0.5 | 50 |

| W16×57 | 16 | 10.03 | 0.3 | 0.56 | 57 |

| W18×60 | 18 | 11.02 | 0.3 | 0.56 | 60 |

| W18×64 | 18 | 11.03 | 0.32 | 0.62 | 64 |

| W21×68 | 21 | 12 | 0.3 | 0.62 | 68 |

| W21×76 | 21 | 12 | 0.34 | 0.69 | 76 |

| W24×84 | 24 | 12 | 0.34 | 0.75 | 84 |

| W24×104(Sizes Available) | 24 | 12 | 0.4 | 0.88 | 104 |

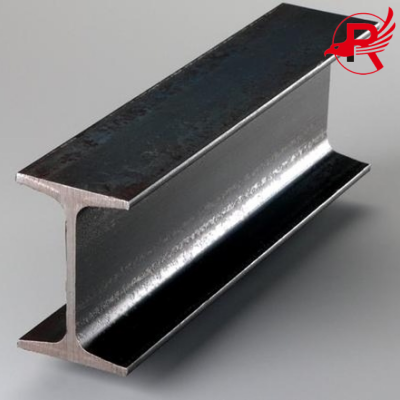

Hot Rolled Black:Standard state

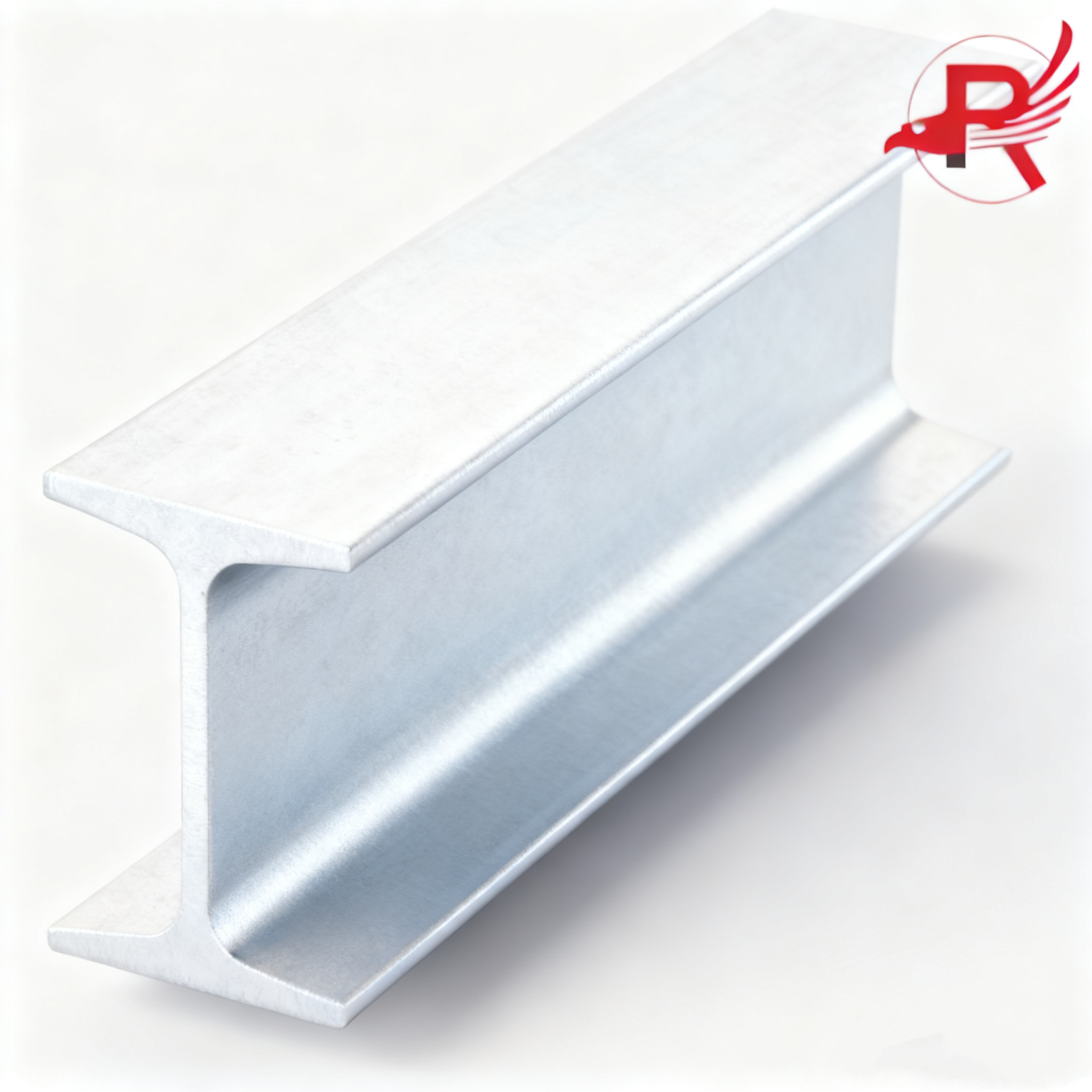

Hot-dip galvanizing: ≥85μm (compliant with ASTM A123), salt spray test ≥500h

Coating: Epoxy primer + topcoat, dry film thickness ≥ 60μm

Building Structures: Beams and columns used in high-rise buildings, factories, warehouses, bridges, etc., providing primary load-bearing support.

Bridge Engineering: Serving as main or secondary beams in bridges, bearing vehicle and pedestrian loads.

Industrial Equipment Support: Supporting large machinery and steel structure platforms.

Structural Reinforcement: Used to modify or reinforce existing building structures, improving their bending resistance and load-bearing capacity.

Building Structure

Bridge Engineering

Industrial Equipment Support

Structural Reinforcement

1) Branch Office - Spanish-speaking support, customs clearance assistance, etc.

2) Over 5,000 tons of stock in stock, with a wide variety of sizes

3) Inspected by authoritative organizations such as CCIC, SGS, BV, and TUV, with standard seaworthy packaging

Comprehensive Protection & Packaging: Each bundle of I-beams is carefully wrapped in tarpaulin, with 2–3 desiccant packs included per bundle, and secured under a heat-sealed, rainproof covering to prevent moisture damage.

Secure Bundling: Bundles are strapped with 12–16 mm Φ steel bands, designed to handle lifting equipment at American ports, supporting 2–3 tons per bundle safely.

Clear Compliance Labeling: Bilingual (English & Spanish) labels are attached to every bundle, providing essential information such as material grade, specifications, HS code, batch number, and test report reference.

Special Handling for Oversized Sections: For I-beams with a cross-sectional height of ≥ 800 mm, the steel surface is coated with industrial-grade anti-rust oil, allowed to dry, and then wrapped in tarpaulin for extra protection.

Efficient Logistics Network: We maintain strong partnerships with leading shipping lines, including MSK, MSC, and COSCO, ensuring reliable and timely transportation.

Quality Assurance: Our operations strictly follow ISO 9001 quality management standards. From packaging material selection to transport allocation, every step is closely monitored to ensure that I-beams arrive in perfect condition, providing a solid foundation for smooth and efficient project execution.

Q: What standards do your I beam steel comply with for Central American markets?

A: Our products meet ASTM A36, A572 Grade 50 standards, which are widely accepted in Central America. We can also provide products compliant with local standards such as Mexico's NOM.

Q: How long is the delivery time to Panama?

A: The sea freight from Tianjin Port to Colon Free Trade Zone takes about 28-32 days, and the total delivery time (including production and customs clearance) is 45-60 days. We also offer expedited shipping options.

Q: Do you provide customs clearance assistance?

A: Yes, we cooperate with professional customs brokers in Central America to help customers handle customs declaration, tax payment and other procedures, ensuring smooth delivery.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506