ASTM A572 Steel Structure Warehouse Steel Structure Building Material

APPLICATION

Steel Frame Building: Built from high strength steel, the building frame is strong, durable and flexible, resistant to earthquakes and strong winds with rapid construction speed and flexible inner space arrangement.

Steel Structure House: Energy saving and environment protection in lightweight steel framing for insulation and fast building.

Steel Structure Warehouse: High bay steel warehouse building designed for two floor project or mezzanine rack with shelf storage warehouse building.

Steel Structure Factory Building: The open design, wide span and strong steel frame makes it perfect for many types of industrial production.

PRODUCT DETAIL

Core steel structure products for factory construction

1. Main load-bearing structure (adaptable to tropical seismic requirements)

| Product Type | Specification Range | Core Function | Central America Adaptation Points |

|---|---|---|---|

| Portal Frame Beam | W12×30 ~ W16×45 (ASTM A572 Gr.50) | Main roof and wall load-bearing beam | Bolted joints for seismic resistance, optimized section for lighter weight and easier transport |

| Steel Column | H300×300 ~ H500×500 (ASTM A36) | Supports floors and frame | Embedded seismic connectors, hot-dip galvanized (zinc ≥85 μm) for humid conditions |

| Crane Beam | W24×76 ~ W30×99 (ASTM A572 Gr.60) | Load-bearing beam for cranes | High-load design (5–20t cranes), end beams with shear-resistant plates |

2. Enclosure system products (weatherproof + anti-corrosion)

Roof Purlins: From C12×20 to C16×31, hot dip galvanized, with a distance of 1.5-2m. They are ideal for color-coated steel panels and typhoon resistance up to level 12.

Wall Purlins: Z10×20 to Z14×26 with anti-rusting paint (dried salt spray over 1000 hours)-also has ventilation holes to ventilate the tropical factory moisture-condition.

Support System: Galvanized round steel Φ12~Φ16 and angle (L50×5 steel angle) for bracing strengthen the sideway stability against the wind force of hurricane).

3. Supporting auxiliary products (localized construction adaptation)

Embedded components: Hot-dip galvanized steel plate (10–20 mm thickness) for concrete footing, popular in Costa Rica and other Central American countries.

Bolts: Instead of welding at the job site, high strength bolts (grade 8.8, hot dip galvanized) are used, reducing the erection time.

Fire & Corrosion Protection:Water based intumescent coating (≥1.5 h fire protection), UV resistant acrylic anti-corrosive coating (≥10 years service life), compliant with local environmental requirements.

STEEL STRUCTURE PROCESSING

| Processing Method | Machines Used | Description |

|---|---|---|

| Cutting | CNC plasma/flame cutters, shears | Plasma or flame cutting for steel plates/sections; shearing for thin plates with precise size |

| Forming | Cold bending machine, press brake, rolling machine | Cold bending for C/Z purlins, gutters, edge trims; rolling for round support bars |

| Welding | Submerged arc, manual arc, CO₂ welders | Submerged arc for H-columns/beams; manual welding for gusset plates; CO₂ welding for thin parts |

| Holemaking | CNC drilling, punching machines | Drilling bolt holes with CNC; punching small batches with precise size and position |

| Surface Treatment | Shot/sand blasting machines, grinder, galvanizing line | Rust removal, weld grinding, hot-dip galvanizing for bolts and structural supports |

| Assembly | Assembly platforms, measuring tools | Pre-assembly of columns, beams, and supports; disassembled after dimensional inspection |

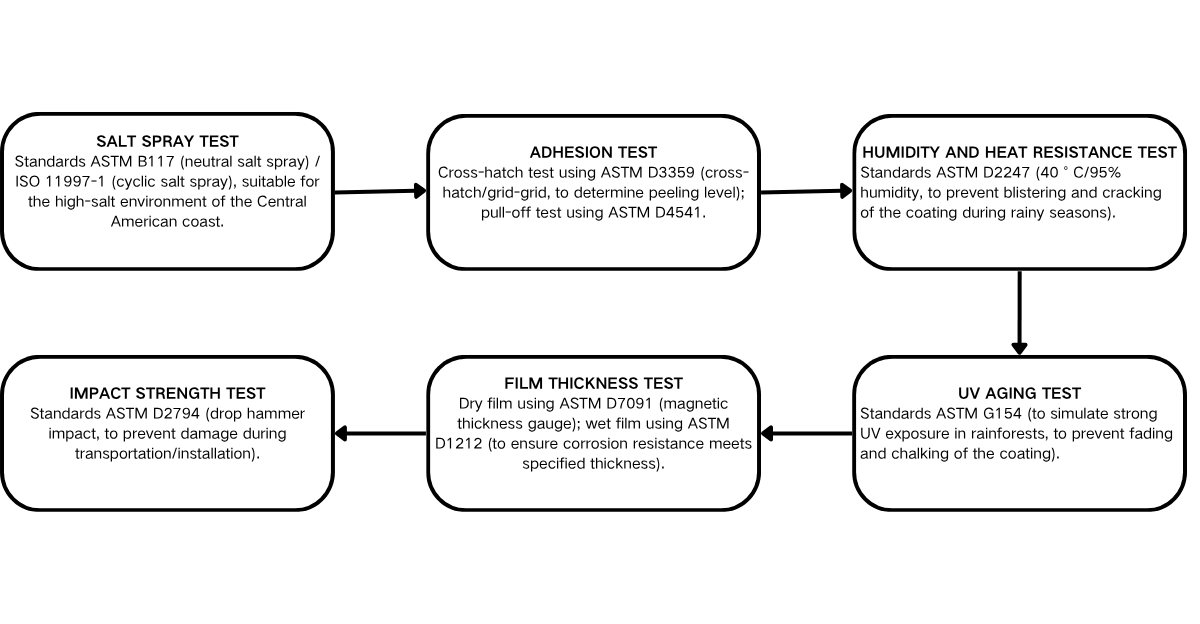

STEEL STRUCTURE TESTING

SURFACE TREATMENT

Surface Treatment Display

-

Epoxy zinc-rich coating

-

Hot-dip galvanized (≥85 μm, 15–20 years lifespan)

-

Black oil coating

PACKAGING AND SHIPPING

Packaging:

-

Steel is tightly packed to protect surfaces and maintain stiffness during handling.

-

Wrapped in waterproof material, plastic, or rust-proof paper; small accessories in wooden boxes.

-

Panels and packs are clearly labeled for safe, efficient unloading and easy installation.

Transportation:

-

Shipped by container or bulk carrier depending on size and destination.

-

Heavy or large parts secured with steel straps and wooden bracing to prevent movement or bending.

-

All shipments meet international transport standards, ensuring safe and timely delivery over long distances or sea transport.

OUR ADVANTAGES

Spanish Support Abroad

Our overseas teams speak Spanish and assist clients in LATAM and EU with communication, customs, documentation, and logistics for smooth, efficient service.

Ready Stock

We keep ample inventory of H-beams, I-beams, and other materials for quick delivery and urgent project needs.

Professional Packaging

Products are packed to sea transport standards with steel-frame pallets, waterproof covers, and corner protection, ensuring safe handling and delivery.

Efficient Shipping

With trusted shipping partners and flexible terms (FOB, CIF, DDP), we guarantee on-time delivery and reliable sea or rail tracking.

FAQ

Q: What are the specifications of your steel structures?

A: Our steel are American standards used like ASTM A36, A572, A588. A36 is a non-alloy steel having good formability and weldability; A588 is weather-resistant for indoor and outdoor use.

Q: How is steel quality guaranteed?

A: From trusted mills with stringent QC. All steel is tested for chemical, mechanical, and undergoes NDE (ultrasonic, magnetic particle) testing.

Q: How to control the rust in hot and humid areas?

A: We apply hot-dip galvanizing (zinc ≥85 μm). For additional protection, acrylic anti-corrosion paint offers 10 years of UV protection and durability.

Q: Corrosion treatment and strength of steel does it have impact on steel?

A: No. Galvanizing or other anti-corrosion treatments can protect steel without diminishing strength, maintaining performance and extending service life.

Q: Are your products designed to meet the seismic requirements in the Americas?

A: Yes. We employ high-seismic-resistant nodes (bolt-connected joints), as well as conduct local seismic intensity-based calculations so as not to cause brittle weld failures.

Q: How about the stability for the whole structure?

A: Designs Include the well organized load-bearing (portal frame , columns, crane beams) and the supporting system (tie bars, corner braces) which has double function of lateral stability reinforcement under normal and extreme.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506