ASTM A992 Steel Structure Warehouse Steel Structure Building Material

APPLICATION

Steel Structure Building: Constructed based on high-strength steel, the building structure has good earthquake resistance and wind resistance, rapid construction and flexible interior space.

Steel Structure House: It has energy saving, environment protection, insulation and fast building features adopting lightweight steel framing.

Steel Structure Warehouse: For large span and high space utilization, Designed to handle heavy duty storage racks and customized racking system.

Steel Structure Factory Building: The open design, wide span and strong steel frame makes it perfect for many types of industrial production.

PRODUCT DETAIL

Core steel structure products for factory construction

1. Main load-bearing structure (adaptable to tropical seismic requirements)

| Product Type | Specification Range | Core Function | Central America Adaptation Points |

|---|---|---|---|

| Portal Frame Beam | W12×30 ~ W16×45 (ASTM A572 Gr.50) | Roof and wall main load-bearing beam | Seismic-resistant bolted joints, optimized cross-section for lighter weight and easier transport |

| Steel Column | H300×300 ~ H500×500 (ASTM A36) | Supports frame and floors | Embedded seismic connectors, hot-dip galvanized (zinc ≥85μm) to resist humid conditions |

| Crane Beam | W24×76 ~ W30×99 (ASTM A572 Gr.60) | Industrial crane load-bearing beam | High-load capacity (for 5–20t cranes), end beams with shear-resistant connection plates |

2. Enclosure system products (weatherproof + anti-corrosion)

Roof Purlins: C12×20 to C16×31, hot-dip galvanized, with a spacing of 1.5–2 m. Suitable for color-coated steel panels and typhoon resistance up to level 12.

Wall Purlins: Z10×20 to Z14×26 with anti-corrosion paint and has ventilation holes to prevent moisture build up in tropical factory conditions.

Support System: Hot dipped galvanized round steel Φ12–Φ16 and corner braces (L50×5 steel angle) for bracing enhance the sideways stability against the force of hurricane winds).

3. Supporting auxiliary products (localized construction adaptation)

Embedded components: Hot-dip galvanized steel plates (10–20 mm thickness) for concrete foundations, popular in Costa Rica and others in Central America.

Bolts: On site welding is replaced by high-strength bolts (Grade 8.8, hot-dip galvanized) which cuts down on the construction time.

Fire & Corrosion Protection: Water-based intumescent coating (≥1.5 h fire resistance) and UV-resistant acrylic anti-corrosive coating (≥10 years service life), complying with local environmental regulations.

STEEL STRUCTURE PROCESSING

| Processing Method | Machines Used | Description |

|---|---|---|

| Cutting | CNC plasma/flame cutters, shearing machines | CNC plasma/flame cutting for steel plates and sections; shearing for thin plates with precise dimensions |

| Forming | Cold bending machine, press brake, rolling machine | Cold bending for C/Z purlins, gutters, and edge trims; rolling for round support bars |

| Welding | Submerged arc welder, manual arc welder, CO₂ welder | Submerged arc welding for H-columns and beams; manual welding for gusset plates; CO₂ welding for thin-walled parts |

| Holemaking | CNC drilling machine, punching machine | CNC drilling for bolt holes; punching for small batches with accurate diameter and position |

| Surface Treatment | Shot/sand blasting machines, grinder, galvanizing line | Rust removal, weld grinding for deburring, hot-dip galvanizing for bolts and structural supports |

| Assembly | Assembly platforms, measuring fixtures | Pre-assembly of columns, beams, and supports; disassembled after dimensional checks for shipment |

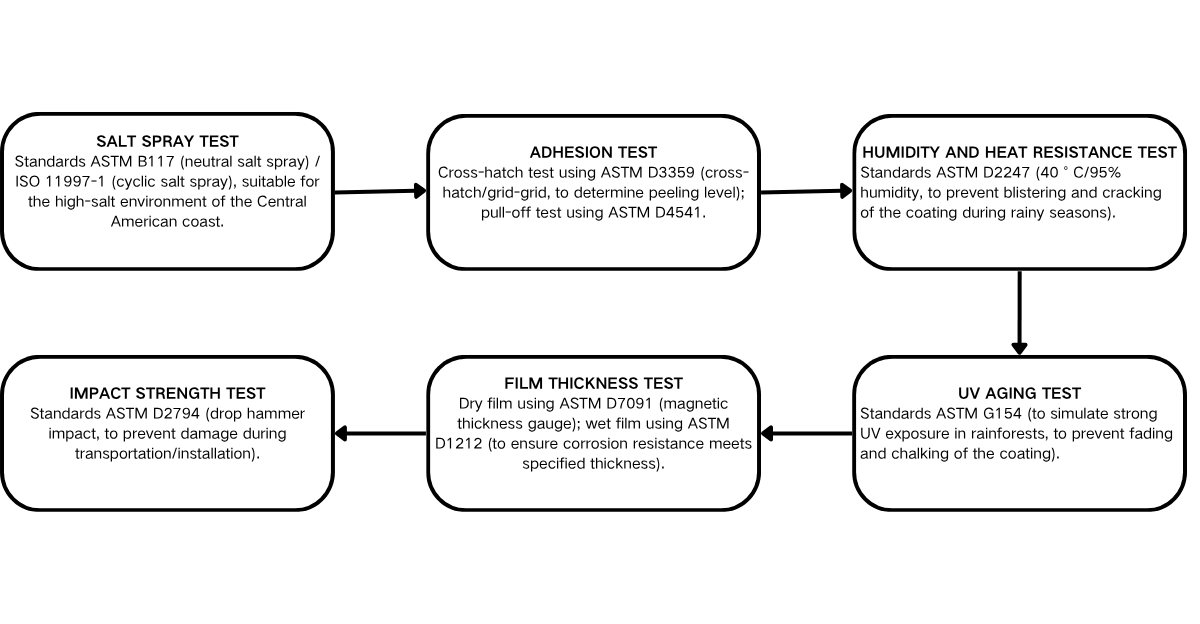

STEEL STRUCTURE TESTING

SURFACE TREATMENT

Surface Treatment Display:

-

Epoxy zinc-rich coating

-

Hot-dip galvanized (layer thickness ≥85 μm, service life 15–20 years)

-

Black oiled finish

PACKAGING AND SHIPPING

Packaging:

The steel is compressed to shield the surface and maintain stiffness in the processing and shipping. Products are usually packaged in waterproof wrapping, plastic or rust-proof paper, and small accessories are packed in wooden box. Each panel or pack has clear labeling for safe and efficient off-loading and for an easy installation on site.

Transportation:

The steel building supplies are transported by container or bulk carrier based on size and destination. Heavy or oversized pieces are strapped with steel and braced with wood to prevent shifting or bowing in transit. Every consignment conforms to international transport standards offering prompt delivery and safe handling for distance/labor and over sea transport.

OUR ADVANTAGES

1.Spanish Support from Abroad

Our foreign teams are Spanish-speaking and attend clients in LATAM and EU in all inquiries through communication, customs, documents and logistics to provide a smoother and more efficient service.

2.Ready Stock for Fast Supply

We maintain sufficient stock of H-beams , I-beams, and other building materials for quick delivery and to meet urgent project needs.

3.Professional Packaging

Products are packed according to sea transport standards with steel frame pallets, waterproof covers and corner protectors, which allows safe handling and deliver without damage.

4.Prompt Shipping & Delivery

With reliable partners in shipping and flexible terms (FOB, CIF, DDP), we can assure you the punctual delivery and dependable sea/rail tracking.

FAQ

Q: What standards do your steelwork comply with?

A: Our steel is to American standards for example ASTM A36, A572, A588. A36 is a plain carbon steel with good formability and weldability, whereas A588 is a weather friendly steel suitable for corrosive atmospheres.

Q: How do you ensure the quality of the steel?

A: We buy our steel from trusted mills that have rigorous QC. All the materials are tested chemically, mechanically, and they are NDE tested (Ultrasonic, MP) to comply with standard.

Q: How can I prevent corrosion problems in a Hot, humid area?

A: Andhot-dip galvaniz (zinc≥85μm) for the moisture proof. For superior corrosion protection, over 10 years despite of UV, acrylic anti-corrosion paints are coated.

Q: Does corrosion prevention treatment impact on the strength of the steel?

A: No, galvanizing, phosphating or anti-corrosion coatings do not reduce the strength. TheyProtect the steel and allow the steel to maintain its performance and service life.

Q: Are your structures capable of meeting seismic requirements in the Americas?

A: Yes. We design high-seismic-resistant nodes (bolt-connected joints) that absorb earthquake energy and prevent brittle weld fractures. Seismic calculations are in accordance with local intensity.

Q: How do you maintain overall stability?

A: The designs employ well thought out load-bearing elements (portal frames, columns, crane beams) and a system of supports (tie bars, corner bracing) that provide lateral stability under both normal and extreme loading conditions.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506