ASTM Standard Custom Welded H-Beam Parts Structural Steel Fabrication for Construction & Steel Structures

Product Detail

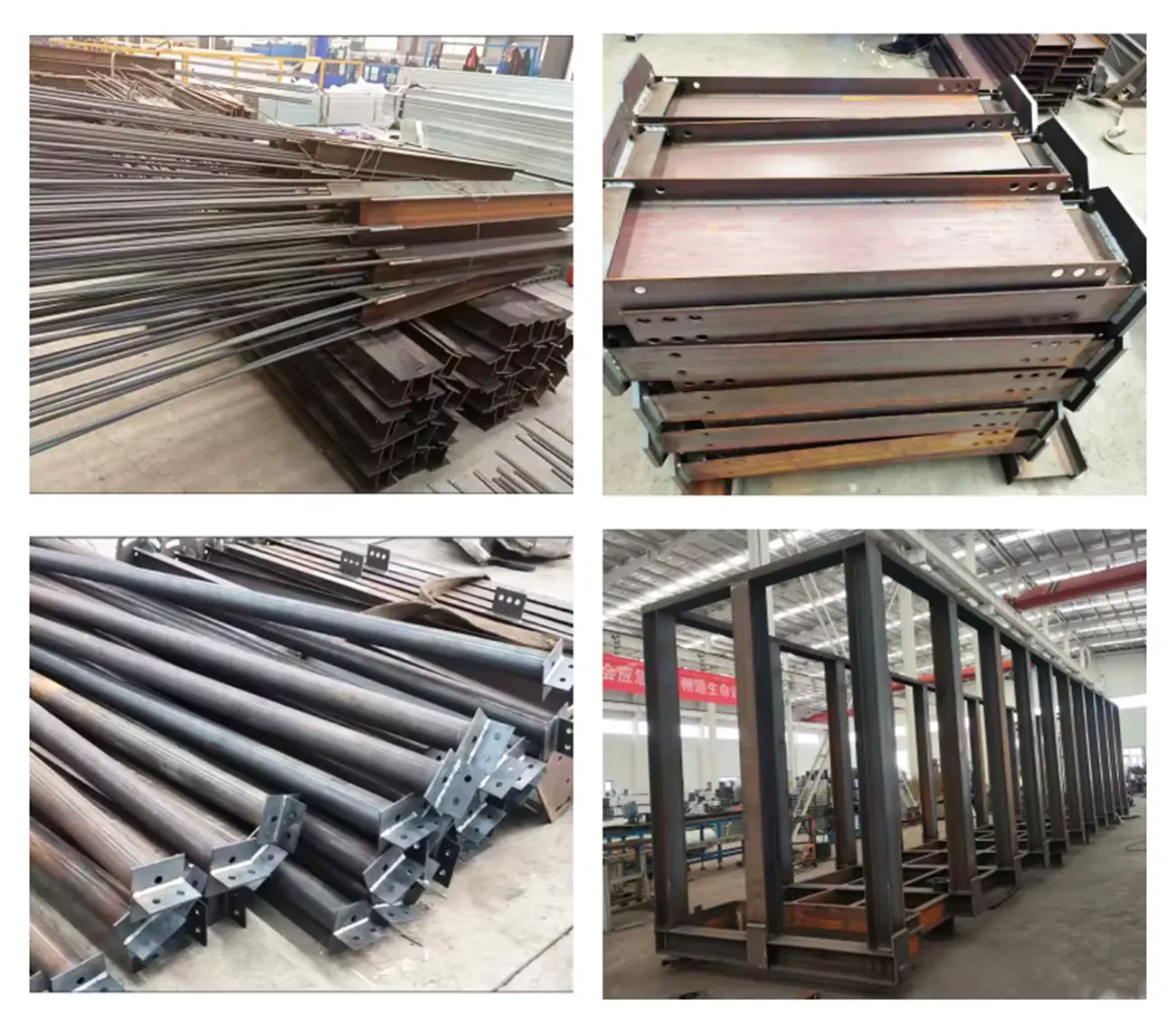

Steel fabrication is a series of processes that start from turning raw steel material into a finished product that can be used for certain purposes. It begins with the choice of the best quality steel, this is the the base for the process. The steel, which is available as beams, sheets, channels, tubes, or rods, then goes through a number of exacting processes to obtain the desired shape and specifications.

Our Service

Key Steps in the Steel Fabrication Process

1.Cutting: When steel is cut to size and shape using methods such as laser cutting, plasma cutting or machining. Selection of cutting gas depends on the thickness of metal, the cutting speed, and type of cutting.

2.Forming: Bending and stretching cold forming techniques – the formed steel is bent or stretched on a press brake or other equipment after it has been cut. This process is critical in achieving part-to-part similarity.

3.Assembling and Welding: Steel components or parts are fastened by bolting, riveting or welding. Balance in this processing step, contribute to determine how structurally well-shaped and shaped the end product will be.

4.Surface Treatment: The finished products needs be cleaned, galvanized, powder coated or painted to enhance it's look, life and rust resistance.

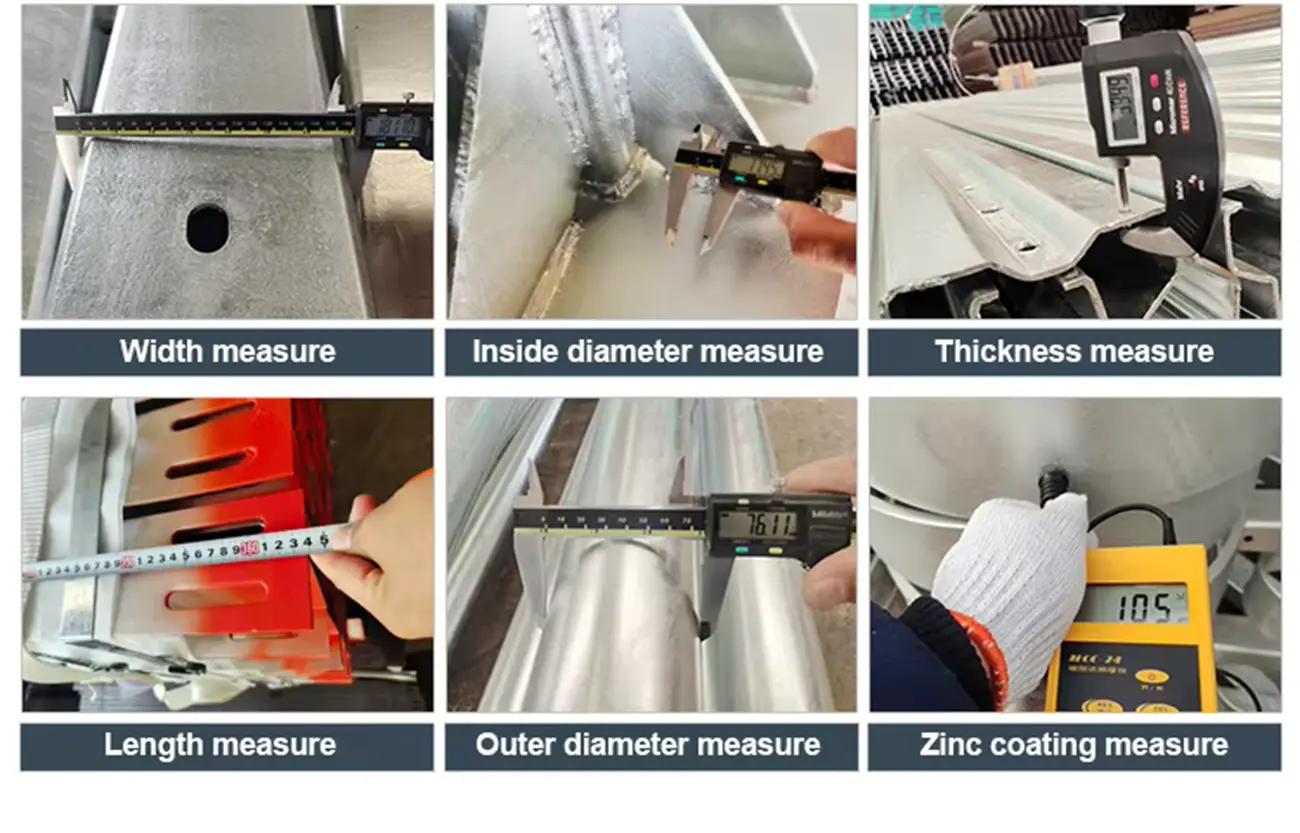

5.Inspection and Quality Checks: Continuous surveillance and inspections during whole of its manufacturing process to assure that the product is well fabricated and fit for use.

Product Specification

| Item | Details |

|---|---|

| Product Name | Custom Steel Fabrication |

| Material | Q235 / Q355 / SS400 / ST37 / ST52 / Q420 / Q460 / S235JR / S275JR / S355JR |

| Standard | GB / AISI / ASTM / BS / DIN / JIS |

| Specification | According to customer drawings |

| Processing | Cutting to length, punching holes, slotting, stamping, welding, galvanizing, powder coating, etc. |

| Package | Bundled or customized packaging |

| Delivery Time | Typically 15 days, depending on order quantity |

Product Testing

Our Advantages

Production Process and Equipment

Packaging & Shipping

FAQ

Q:Are you the manufacturer?

A: Yes, we are a spiral steel tube manufacturer in Daqiuzhuang Village, Tianjin, China.

Q: Can I make a small trial order?

A: Yes, we accept the small order and deliver by LCL (Less than Container Load).

Q:What are your payment terms?

A: 30% T/T in advance, 70% before shipment(FOB) or 70% against BL copy(CIF).

Q:Are samples free?

A: Yes, samples are free, buyer pay for the freight.

Q:Are you a gold supplier and do you support Trade Assurance?

A: Yes, we are 13 years gold supplier and accept Trade Assurance.