China factory direct sales building materials new C-shaped steel

Product Detail

Definition:

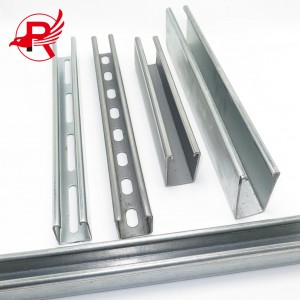

Strut C channel, also known as C-Channel, is a type of metal framing channel that is commonly used in construction, electrical, and industrial applications. It has a C-shaped cross-section with a flat back and two perpendicular flanges.

Material:

It is generally made of galvanized steel for protection against rusting or stainless steel for superior rusting resistance.

Sizes:

2 widths are available: 5/8” x 1 5/8” x 1 5/8” & 5/8” x 3” x 1 1/2” You can also get the other sizes up to 4” x 2”.

Applications:

Strut is used for general structural support, cable and pipe routing, equipment mounting, shelving and a myriad of industrial applications.

Installation:

Easily assembled with fittings, brackets and clamps, they can be attached to walls, ceilings or infrastructure with screws, bolts or welds.

Load Capacity:

Load ratings depend on size and material, vendors provide load tables for safe installation.

Accessories:

Works with spring nuts, clamps, threaded rod, hangers, brackets and pipe supports to create a dynamic system.

|

SPECIFICATIONS FOR H-BEAM |

|

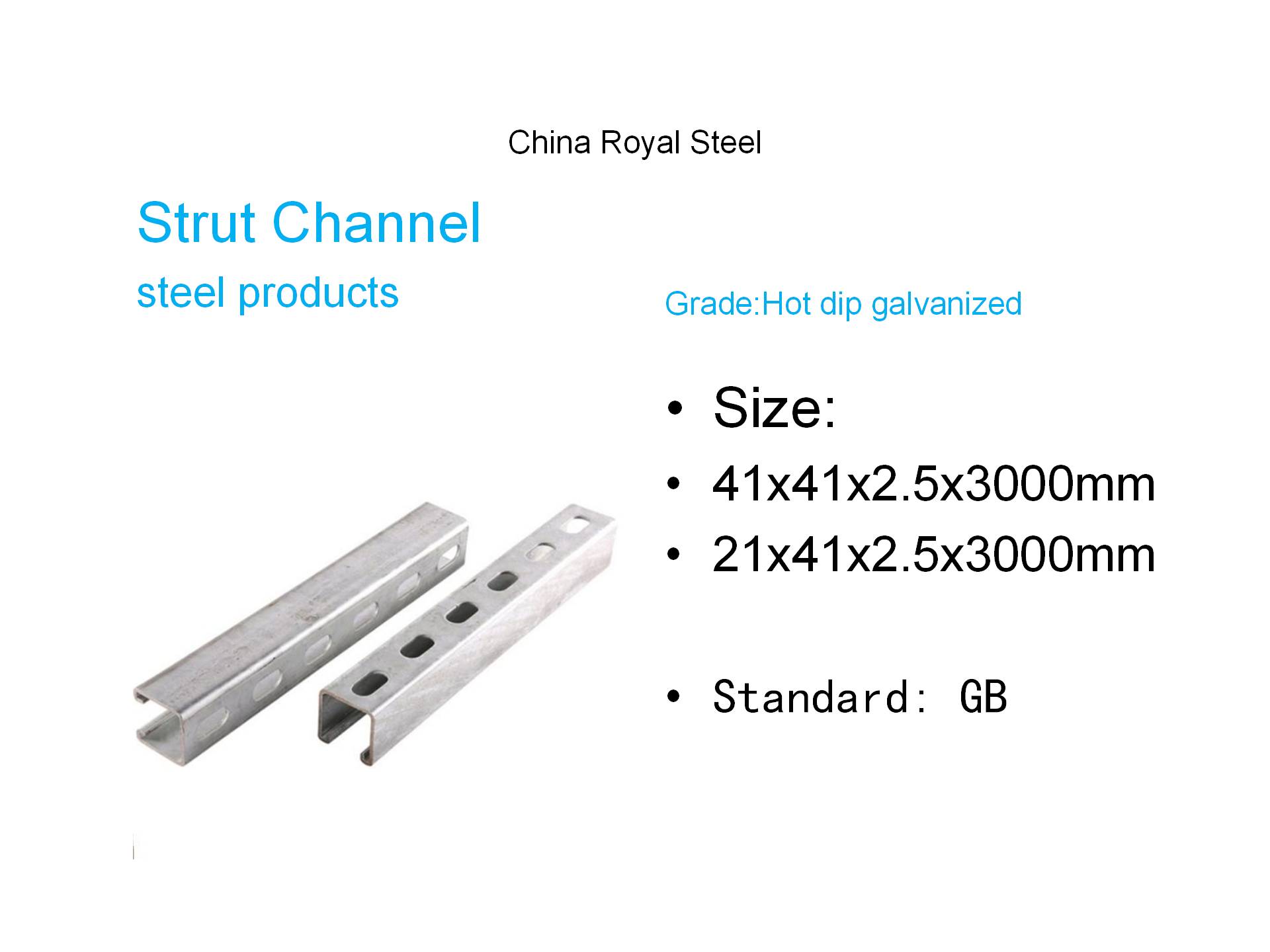

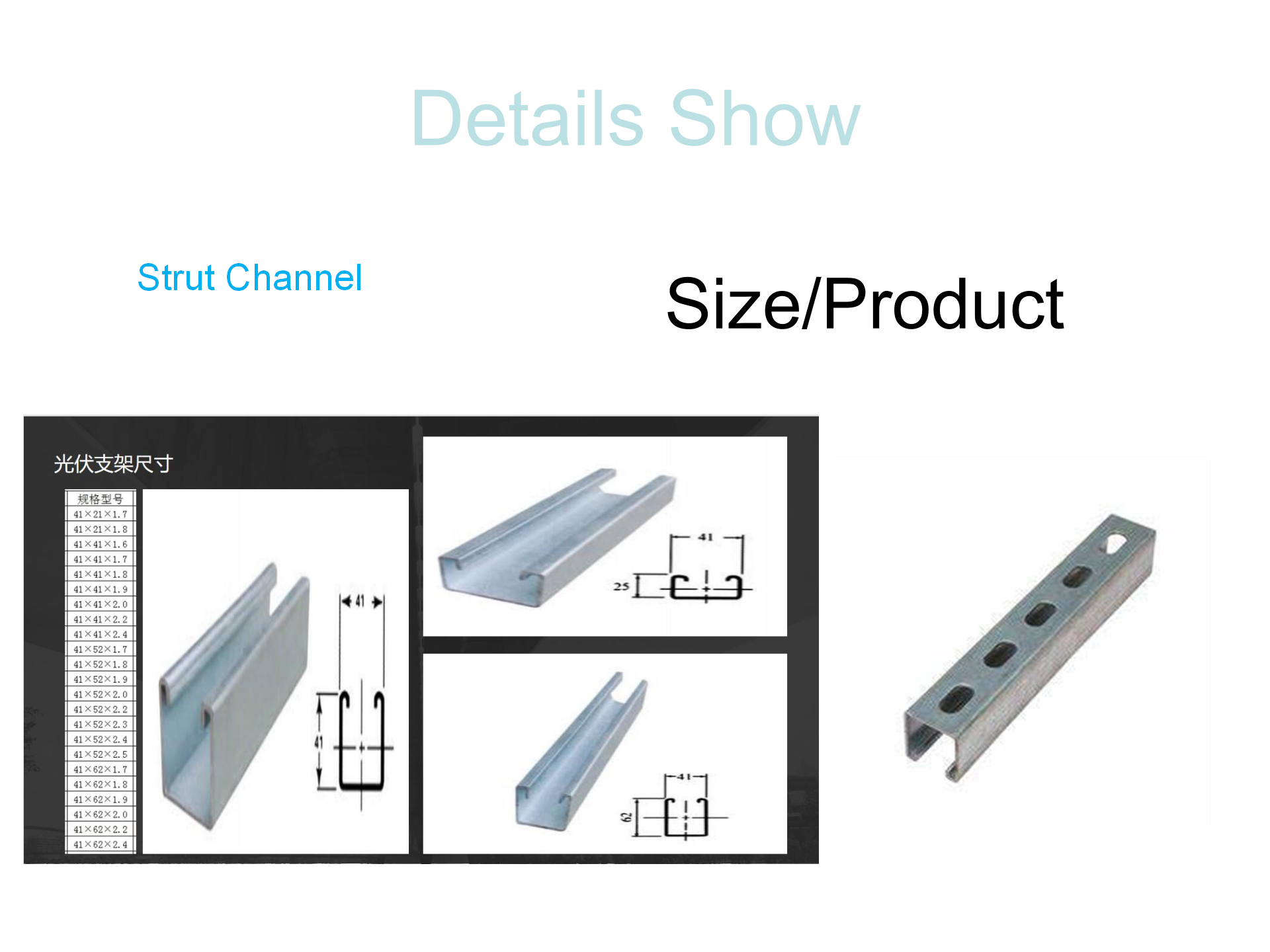

| 1. Size | 1) 41x41x2.5x3000mm |

| 2)Wall Thickness:2mm,2.5mm,2.6MM | |

| 3)Strut Channel | |

| 2. Standard: | GB |

| 3.Material | Q235 |

| 4. Location of our factory | Tianjin,China |

| 5. Usage: | 1)rolling stock |

| 2)Building steel structure | |

| 3Cable tray | |

| 6. Coating: | 1) galvanized

2) Galvalume 3) hot dip galvanized |

| 7. Technique: | hot rolled |

| 8. Type: | Strut Channel |

| 9. Section Shape: | c |

| 10. Inspection: | Client inspection or inspection by 3rd party. |

| 11. Delivery: | Container, Bulk Vessel. |

| 12. About Our Quality: | 1) No damage, no bent

2) Free for oiled&marking 3) All goods can be checked by third party inspection before shipment |

Features

Versatility:

Applicable for multiple industries such as construction, electrical, and industrial with adaptable support for components and systems.

High Strength:

The C-profile has good load bearing and rigidity which is suitable for pipes, cable trays and machines etc.

Easy Installation:

Common fasteners can be used for fastening to walls, ceilings or racks in the field because of the standardized dimensions and pre-punched holes.

Adjustability:

With pre-punched holes, reconfiguring brackets, clamps and other accessories is a simple affair should you need to change or upgrade your layout.

Resistance to Corrosion:

Galvanized or stainless steel channel that resists rust for superior performance in corrosive or severe environments.

Fits the full complement of channel accessories:

It including nuts, clamps, bolts, hangers—allowing for easy customization.

Economical:

It offers a strong, economical solution to custom metal fabricating that provides robust structural performance.

Application

Strut Channel are widely used in many different industries and building projects. Here are just a few examples of popular uses:

Roof Photovoltaic :Power Generation System Strut Channel and the roof are used to install the photovoltaic modules to become a distributed photovoltaic power station in combined roof of urban buildings or feeble of land. The power from photovoltaic modules in urban buildings or place with hard land use is used, and the location requirement can be lowered.

Ground photovoltaic power station: The ground photovoltaic power station is located on the ground and is a central photovoltaic power station. It consists of PV modules, supportstructures and electrical equipment and it can convert the solar energy to electrical energy and feed it into the grid. It is a clean, renewable and more and more popular Construction technology of photovoltaic power station.

Agricultural Photovoltaic System:Place the photovoltaic support near to your field or rise it over or beside some greenhouses to get a two-in-one solution with harvesting and power coverage and grow your crops under shade avoiding direct sunlight while the direct sunlight while generating electricity, solar to reduce the cost in the field.

Other special scenes: For Instance, there are still other fields such as offshore wind power generation, road lighting and so on, which can utilize photovoltaic brackets to erect power stations. Also, we can general contracting for photovoltaic power-station projects the end to the end in the whole county if you are interested in helping energy saving and environmental protection.

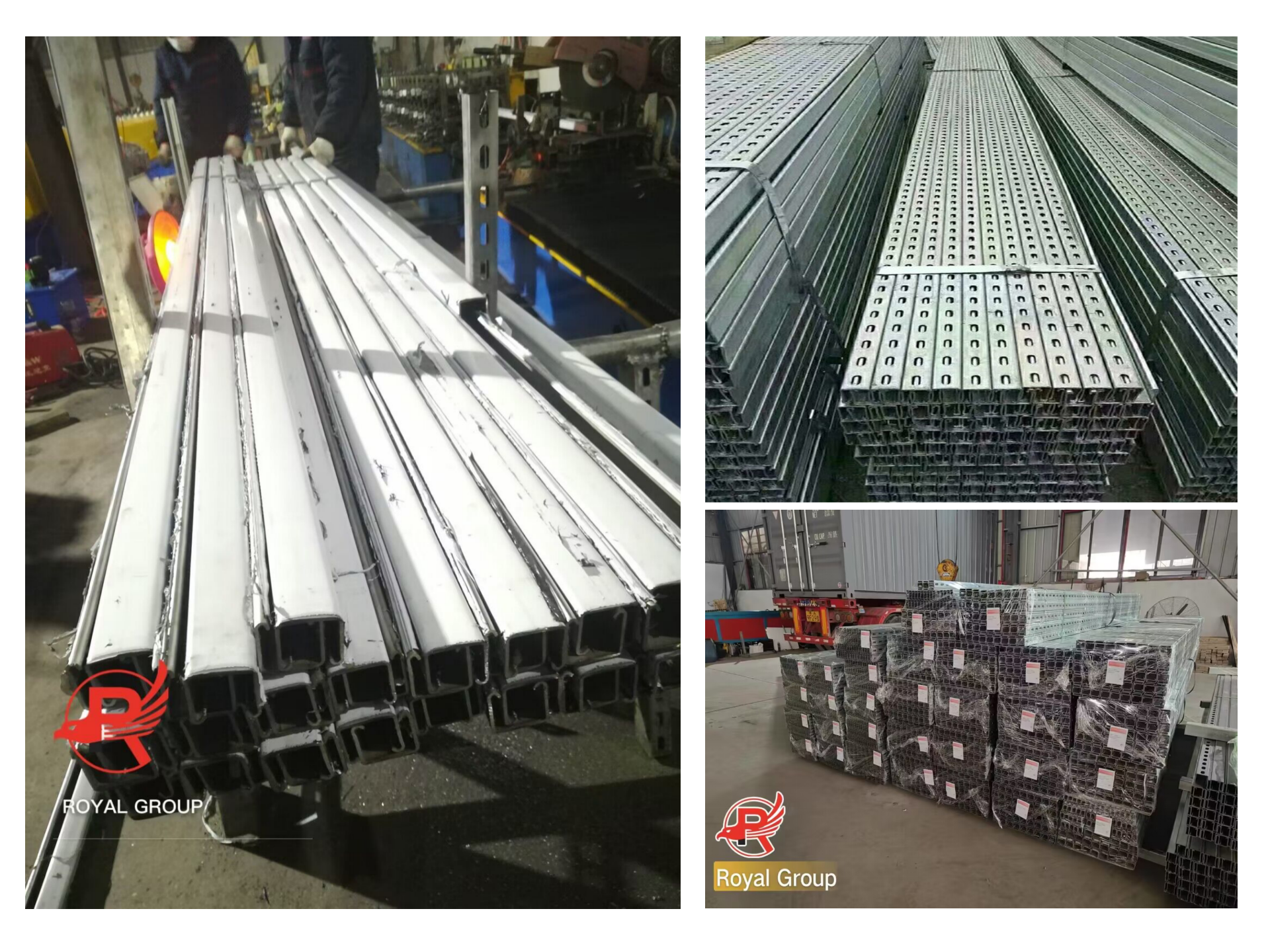

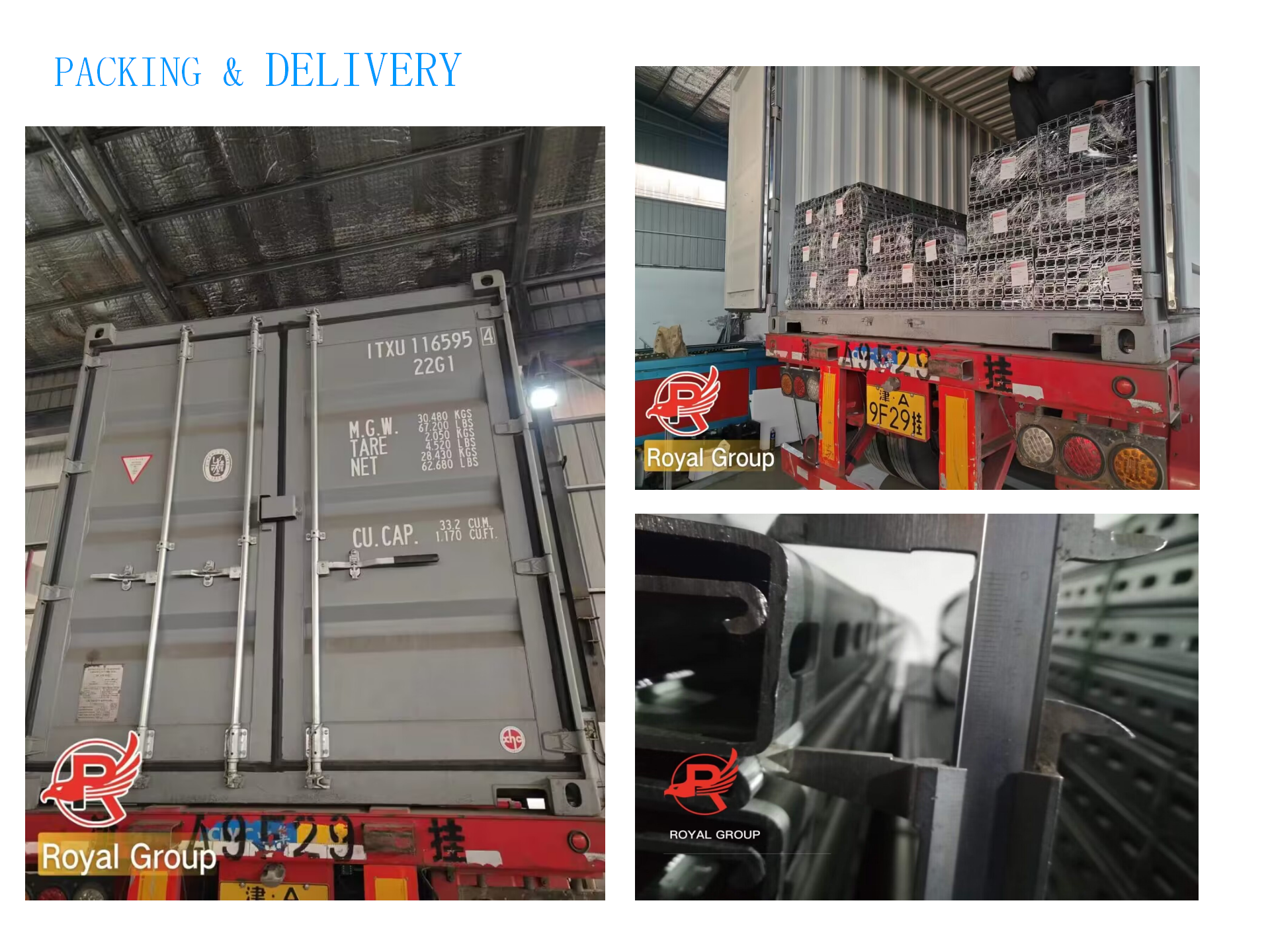

Packaging & Shipping

Packaging:

We provide packaging in bundles for the products. A batch of 500-600kg. A small cabinet weighs 19 tons.The outer layer will be wrapped with plastic film.

Shipping:

Select an appropriate mode of transport: Use the suitable mode of transport according the amount and weight of the Strut Channel, such as Flatbed trucks, Container, Ship. Take into consideration distance, time, cost, and possible regulations for transport.

Utilize proper lifting equipment: Use proper lifting equipment such as crane, forklift, or loader to load and unload the Strut Channel. Make sure that the equipment used are capable of supporting the weight of the sheet piles safely.

Fasten the load: Tie or brace the packaged stack of Strut Channel adequately within the transport vehicle to keep the stack from moving, sliding or falling while in transit.

FAQ

1.How can I get a quotation?

Leave us a message and we will reply promptly.

2.Will you deliver on time?

Yes, we guarantee high-quality products and on-time delivery.

3.Can I get samples before ordering?

Yes, samples are available for free, and we can produce according to your samples or drawings.

4.What are your payment terms?

Typically 30% deposit and the balance against the B/L.

5.Do you accept third-party inspection?

Yes, we fully accept it.

6.How can we trust your company?

We have years of experience as a verified steel supplier, with our headquarters in Tianjin. You are welcome to verify us through any method.