China Factory Direct Sales Price Preferential Quality Reliable U Steel Sheet Pile

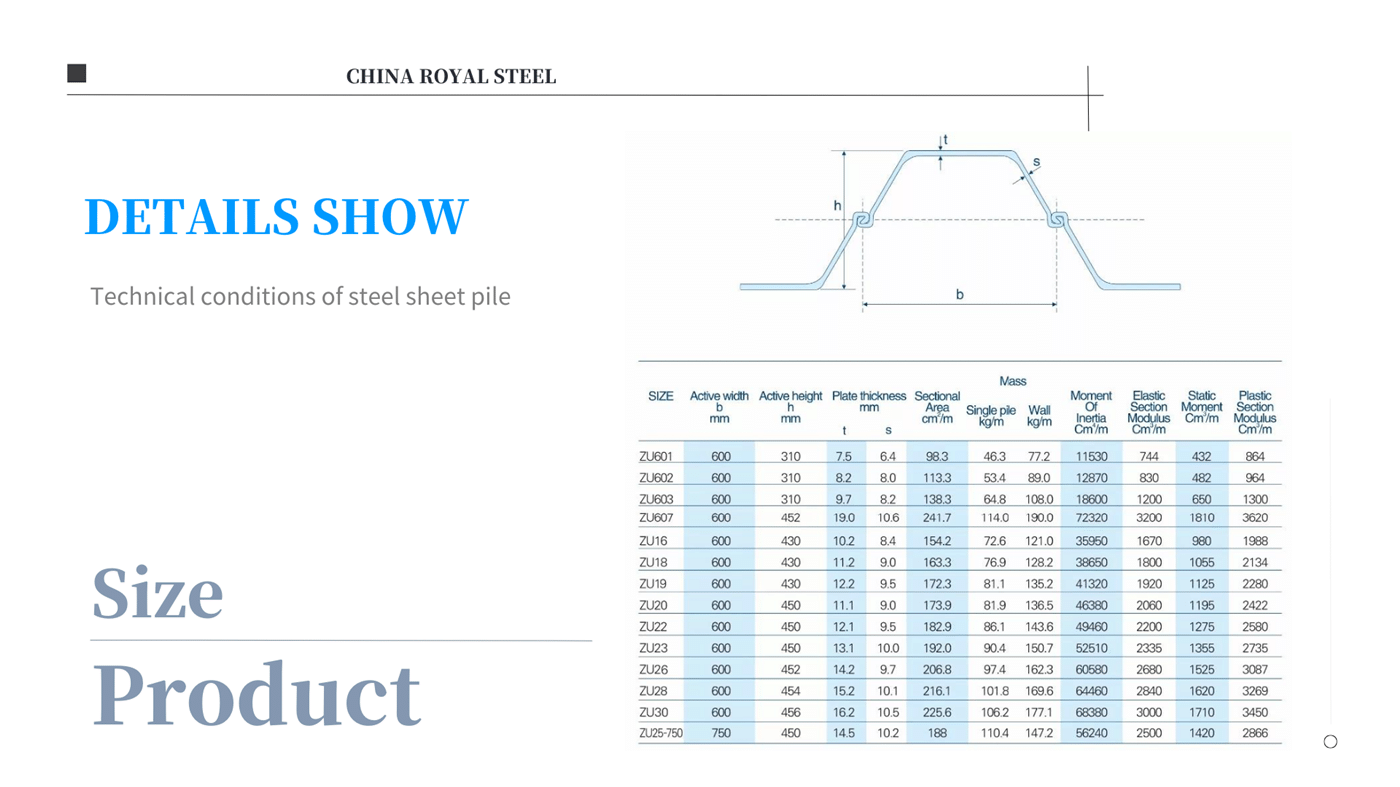

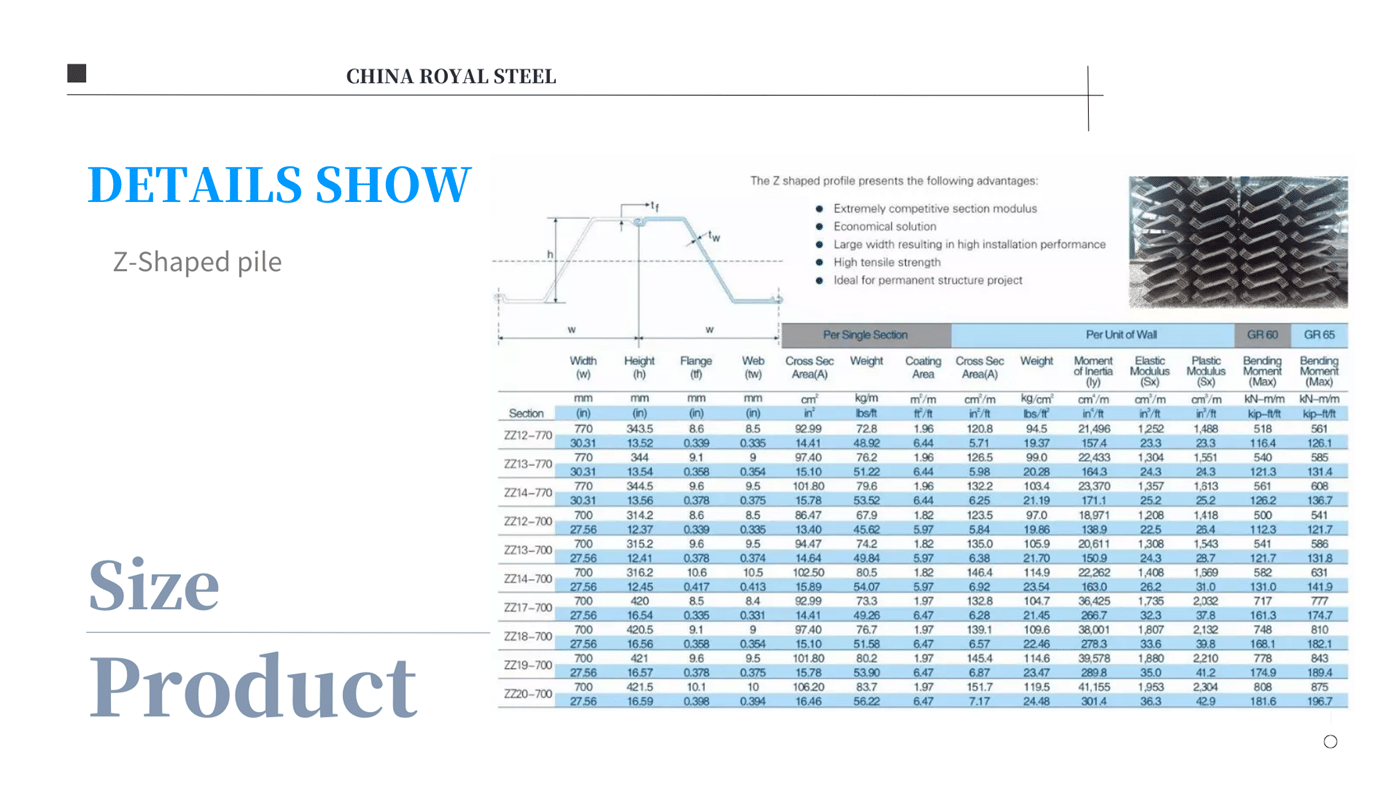

Product Details – Steel Sheet Piles

-

Product Name: Steel Sheet Pile / Sheet Piles Steel

-

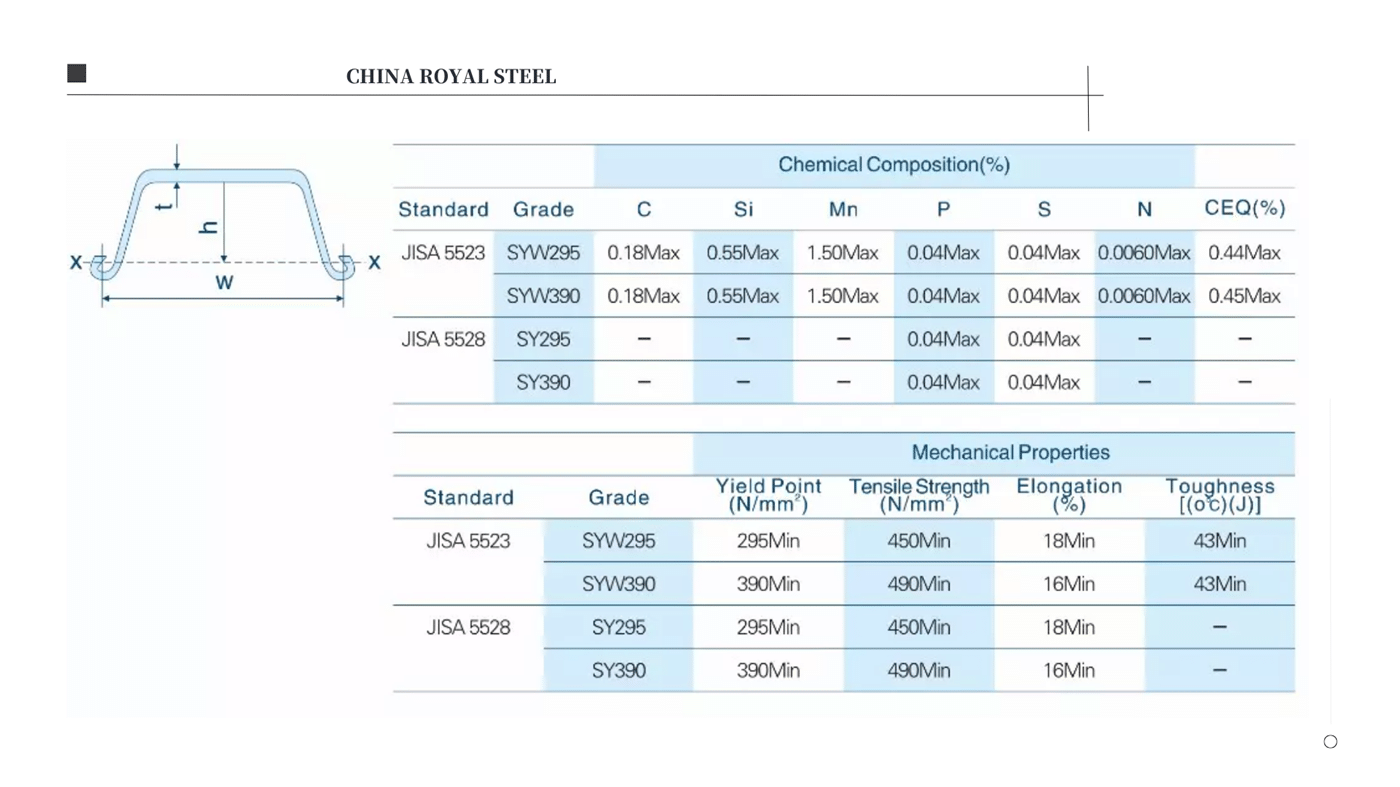

Steel Grade: S275, S355, S390, S430, SY295, SY390, ASTM A690

-

Standards: EN10248, EN10249, JIS5528, JIS5523, ASTM

-

Delivery: 1 week; 80,000 tons in stock

-

Certificates: ISO9001, ISO14001, ISO18001, CE FPC

-

Dimensions: Custom width × height × thickness

-

Length: Single lengths up to 80 m

-

We manufacture all types of sheet piles, pipe piles, and related accessories, with full flexibility in width, height, and thickness.

-

Single lengths of over 100 m can be produced, with in-house painting, cutting, welding, and other fabrication services.

-

Fully certified to international standards, including ISO 9001, ISO 14001, ISO 18001, CE, SGS, and BV.

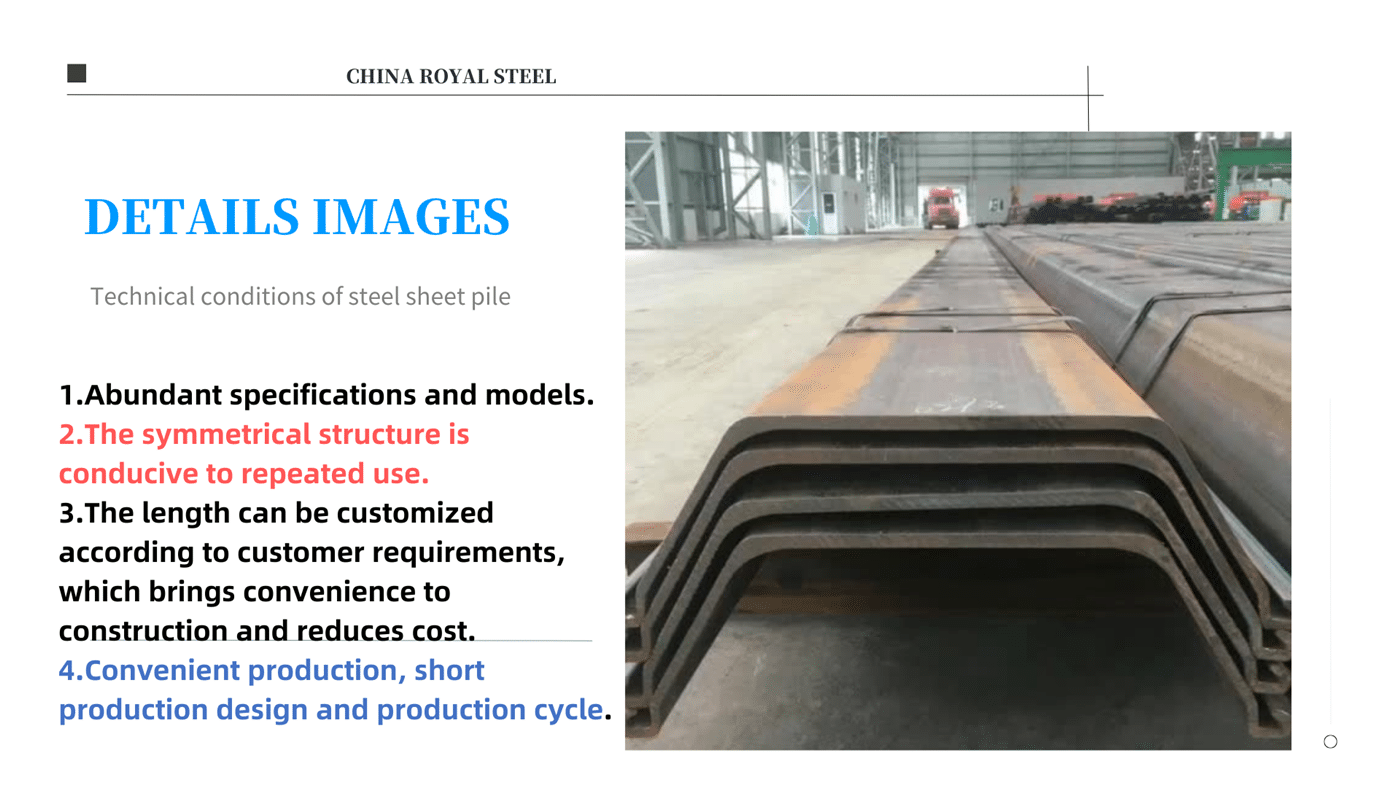

Features

Understanding Steel Sheet Piles

Steel sheet piles are long, interlocking sections driven into the ground to form continuous retaining walls. They are widely used in foundation works, underground parking structures, waterfront developments, and marine bulkheads.

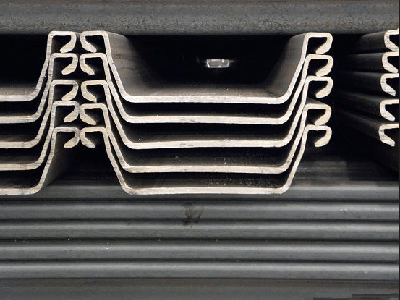

1. Cold-Formed Sheet Piles – Versatile & Cost-Effective

Cold-formed sheet piles are produced by bending thin steel plates into shape. Lightweight and economical, they are easy to handle, transport, and install—making them ideal for moderate-load applications such as retaining walls, temporary excavations, and landscaping projects.

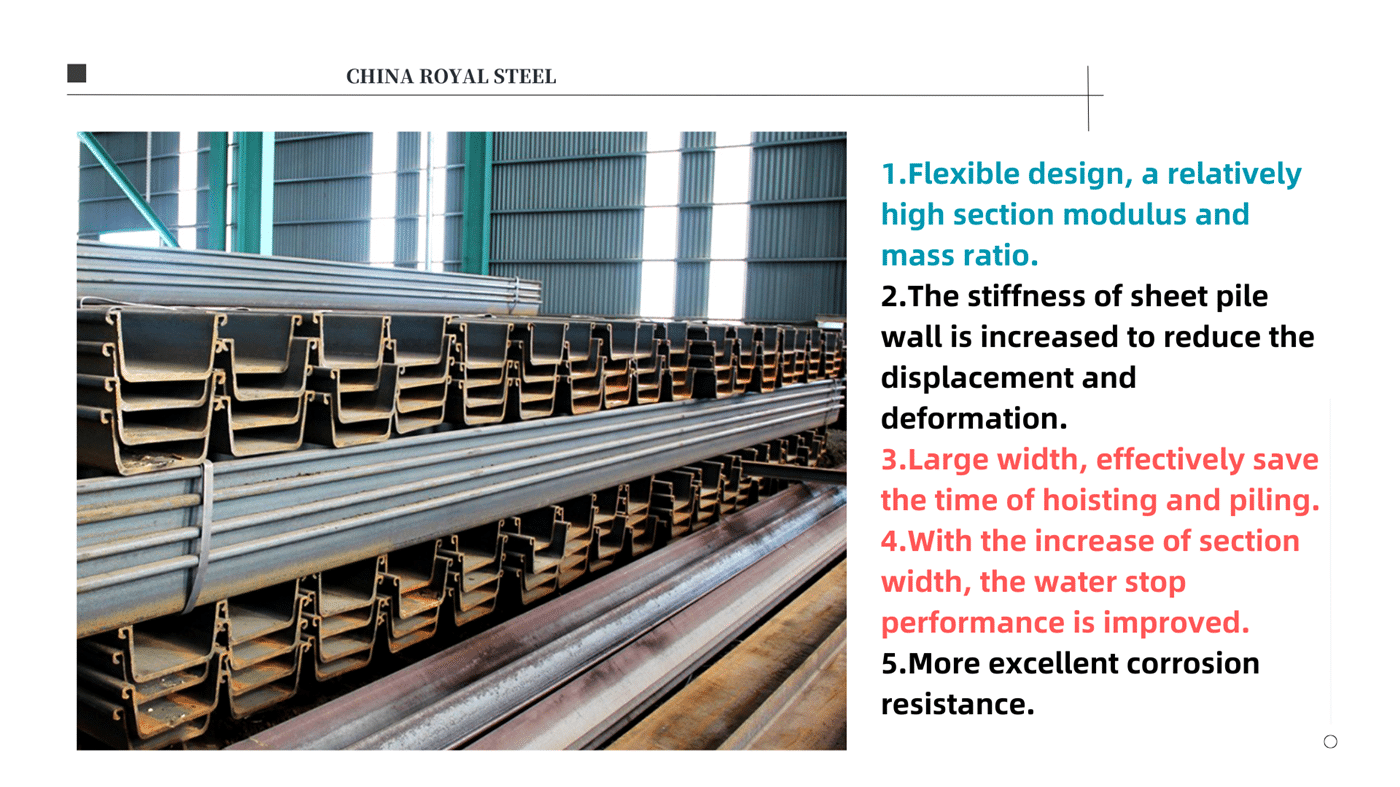

2. Hot-Rolled Sheet Piles – Strong & Durable

Hot-rolled sheet piles are formed at high temperatures, giving them superior strength, durability, and interlocking precision. They are the preferred choice for heavy-duty projects like deep excavations, ports, flood control systems, and high-rise foundations.

Benefits of Steel Sheet Pile Walls

1. Strength and Stability

Steel sheet piles deliver exceptional strength and structural stability, capable of withstanding high soil and water pressure for long-lasting performance in demanding environments.

2. Versatility

Available in multiple types and sizes, sheet piles can be customized to suit diverse ground conditions and design requirements — including curved, inclined, or irregular structures.

3. Environmental Sustainability

Made from recyclable steel, sheet piles help reduce carbon emissions and support sustainable construction practices.

4. Cost-Effectiveness

Durable, low-maintenance, and quick to install, steel sheet piles lower overall project costs by saving both time and labor.

Application

Hot rolled steel sheet piles are commonly used in various applications, including:

1. Retaining Walls

Used to prevent soil erosion, stabilize slopes, and provide structural support for constructions near excavations or water bodies.

2. Harbors and Ports

Widely applied in docks, quays, breakwaters, and other marine structures, steel sheet piles resist water pressure and protect coastlines from erosion.

3. Flood Protection

Installed along rivers and waterways to form flood barriers, preventing inundation during heavy rainfall or flood events.

4. Underground Structures

Ideal for basements, tunnels, and underground parking facilities, providing reliable earth retention and water resistance.

5. Cofferdams

Used to build temporary enclosures that isolate construction zones from water or soil, allowing dry and safe working conditions.

6. Bridge Abutments

Provide lateral support and stability for bridge foundations, effectively distributing loads and preventing soil displacement.

Overall, hot-rolled steel sheet piles offer strength, durability, and adaptability across a wide range of projects requiring soil retention, water control, and structural stability.

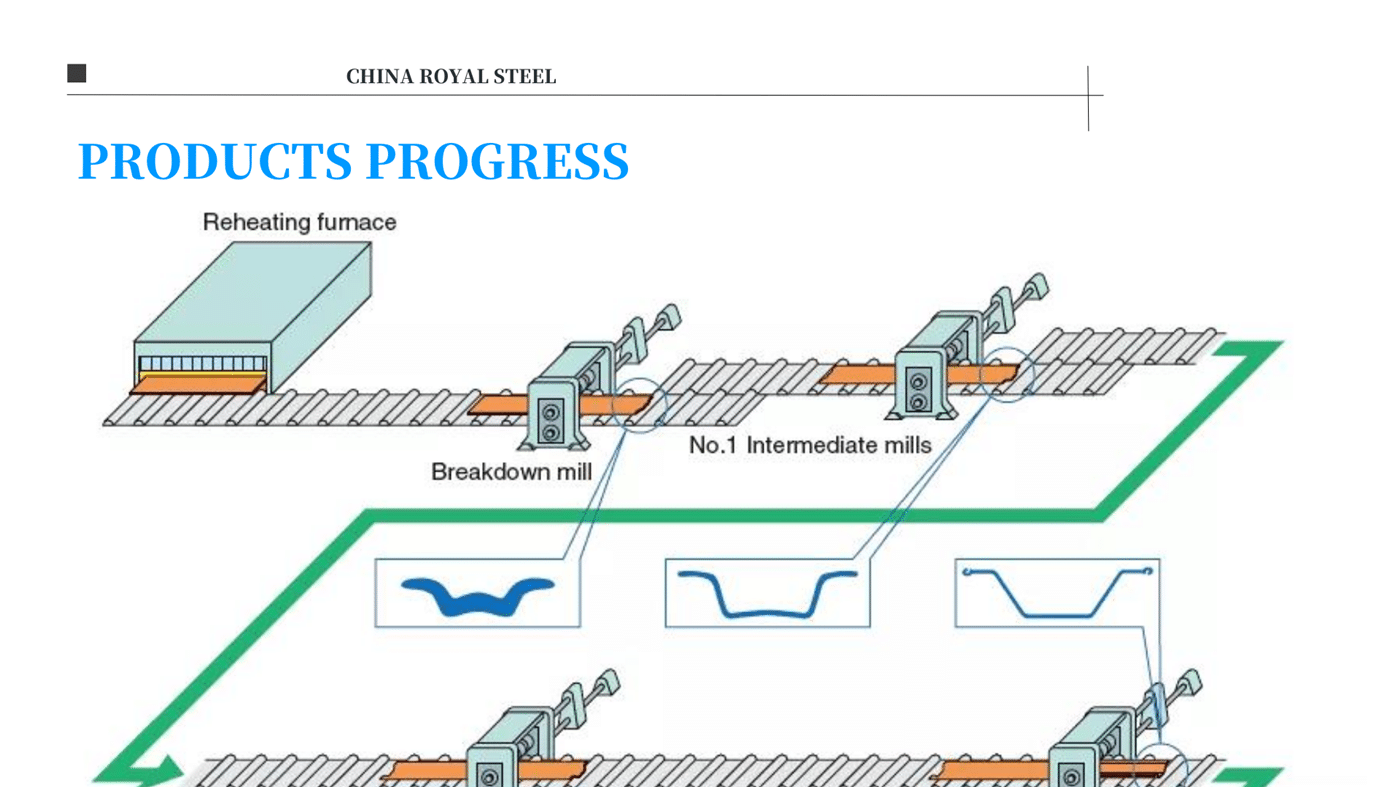

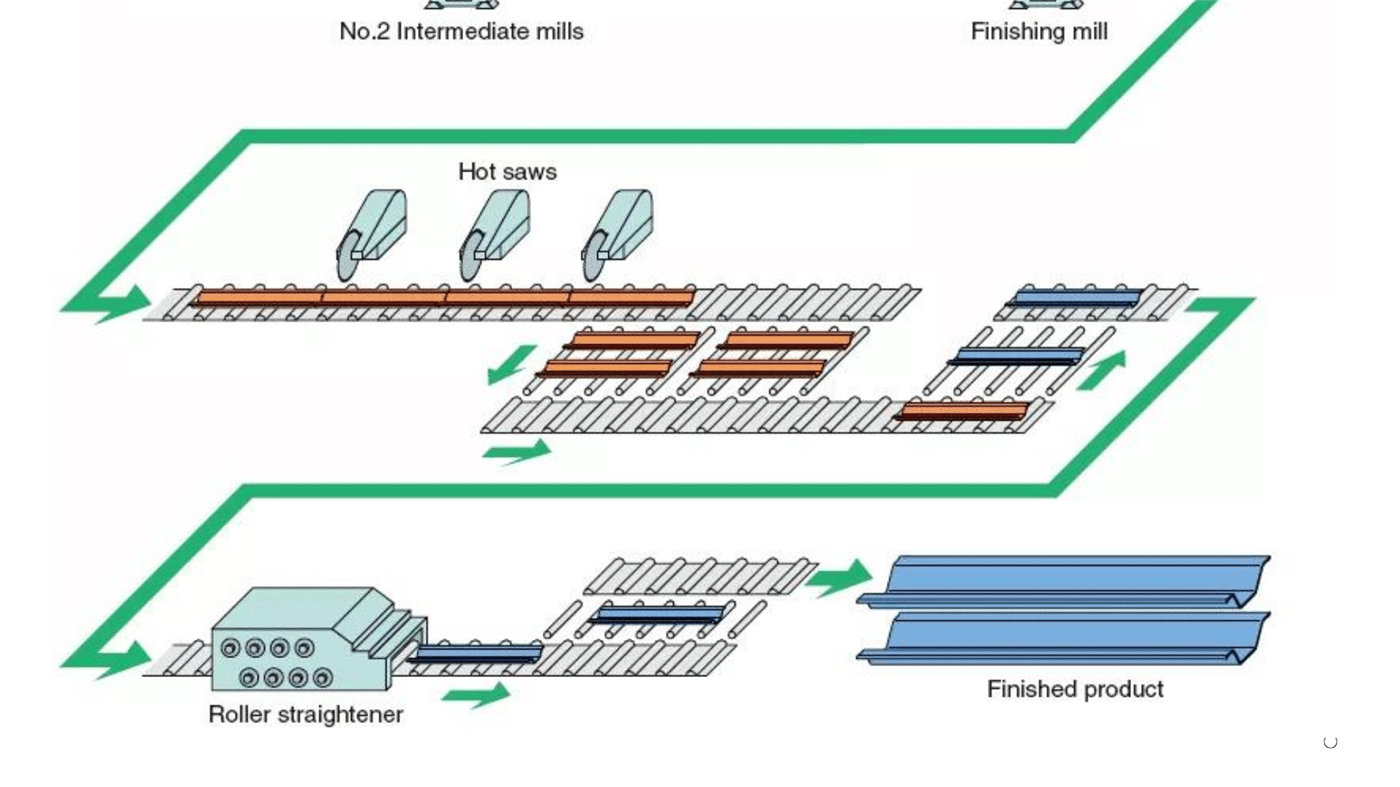

Production Process

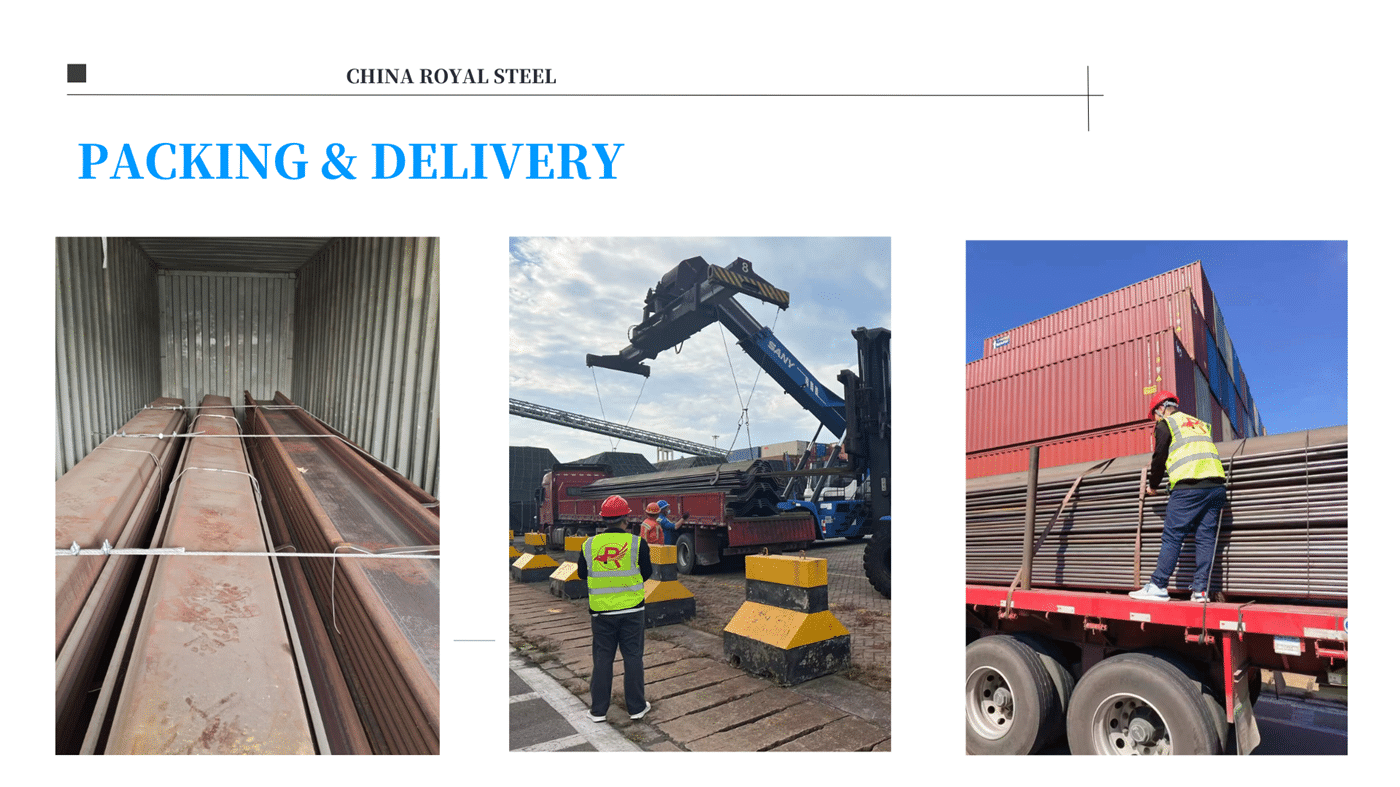

Packaging & Shipping

Packaging:

Stack the Sheet Piles Securely

Arrange the U-shaped sheet piles in a neat and stable stack, ensuring proper alignment to maintain balance and prevent movement. Use steel strapping or banding to secure the stack and avoid shifting during transportation.

Use Protective Packaging Materials

Wrap the stacked sheet piles with moisture-resistant materials such as plastic film or waterproof paper to protect against humidity and environmental exposure. This helps prevent rust, corrosion, and surface damage during transit or storage.

Shipping:

Choose a Suitable Mode of Transportation

Select the appropriate transport method—such as flatbed trucks, containers, or ships—based on the quantity, weight, and destination of the sheet piles. Consider distance, cost, time, and relevant transport regulations.

Use Proper Lifting Equipment

During loading and unloading, use cranes, forklifts, or loaders with adequate capacity to safely handle the weight of the U-shaped steel sheet piles. Ensure all lifting operations follow safety standards.

Secure the Load

Fasten the packaged sheet piles firmly on the transport vehicle using steel strapping, bracing, or other reliable securing methods to prevent movement, sliding, or damage during transit.

Our Customer

FAQ

1. How can I get a quotation?

Leave us a message, and we will respond promptly.

2. Will you deliver on time?

Yes, we guarantee quality products and timely delivery. Honesty is our company principle.

3. Can I get samples before ordering?

Yes. Samples are usually free, and we can produce according to your sample or drawings.

4. What are your payment terms?

Typically, 30% deposit and the balance against B/L.

5. Do you accept third-party inspection?

Yes, third-party inspection is welcome.

6. How can we trust your company?

We are a gold supplier in the steel industry with years of experience. Our headquarters is in Tianjin, and you are welcome to verify in any way.