China Galvanized Pipe Tube Square Carbon Steel Pipe

Product Detail

Specifically, it is mainly used in the following fields:

1. Construction field: such as building frames, steel structures, stair railings, etc.;

2. Transportation field: such as road guardrails, ship structures, automobile chassis, etc.;

3. Metallurgical field: such as pipeline systems for transporting ore, coal, slag, etc.

Product Of Advantages

As a steel pipe product with strong technical content, galvanized pipe has a wide range of uses and many advantages. It is an indispensable pipeline system material in construction, transportation, metallurgy and other fields. In future market demand, galvanized pipes will have wider application prospects.

Main Application

Application

1. Corrosion Resistance: Galvanized pipes are coated with a zinc layer, providing strong corrosion resistance and preventing rust over long periods of use.

2. Durability: Due to the zinc coating, galvanized pipes are highly durable and have a relatively long service life.

3. Aesthetics: Galvanized pipes have a smooth, bright surface and can be used directly without any surface treatment.

4. Plasticity: Galvanized pipes exhibit excellent plasticity during the manufacturing process, allowing them to be manufactured into various shapes as needed.

5. Weldability: Galvanized pipes are easily welded during manufacturing, facilitating installation.

Parameters

|

Product name |

Galvanized Pipe |

| Grade | Q235B, SS400, ST37, SS41, A36 etc |

| Length | Standard 6m and 12m or as customer requirement |

| Width | 600mm-1500mm, according to customer's requirement |

| Technical | Hot Dipped Galvanized pipe |

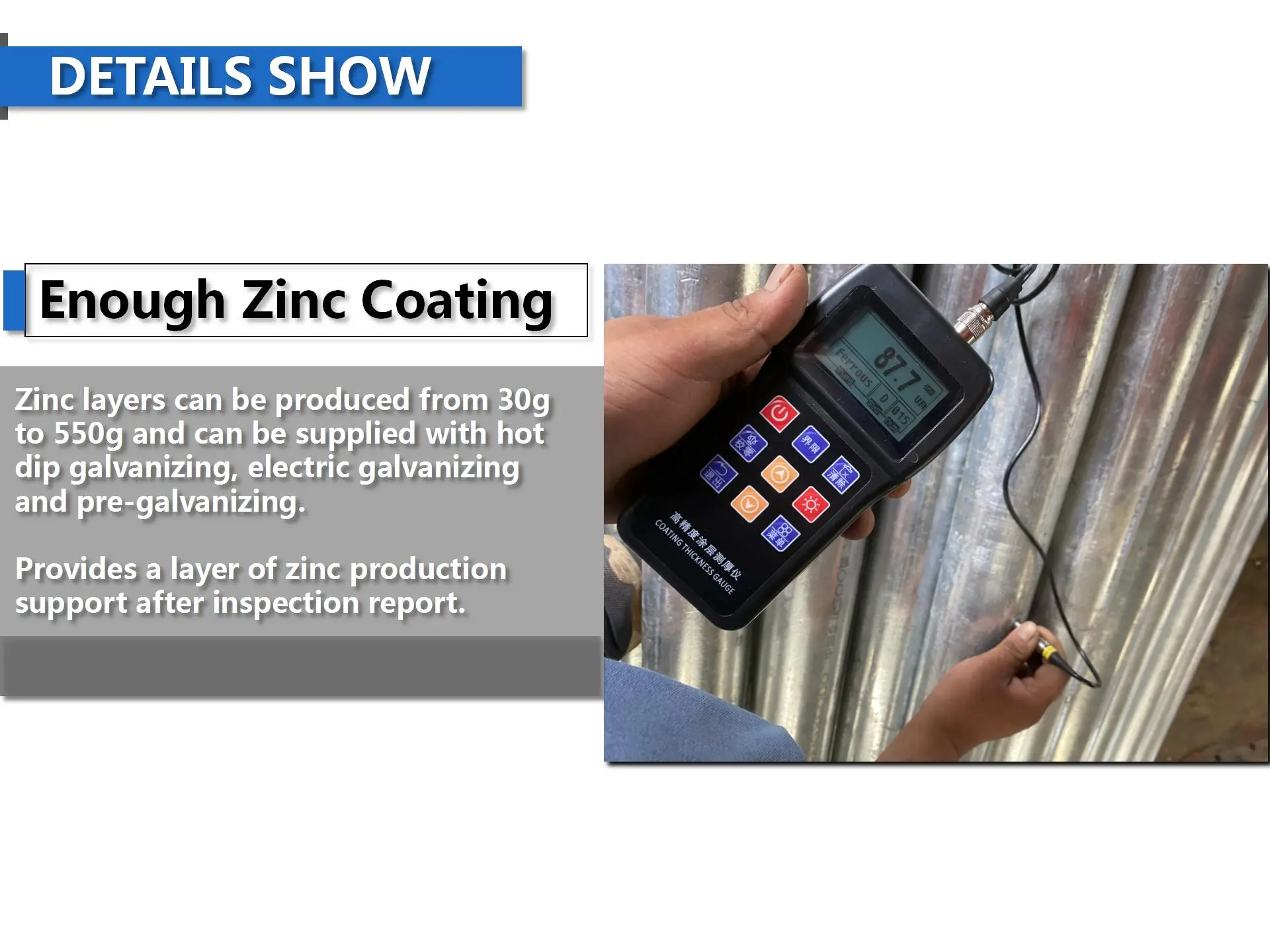

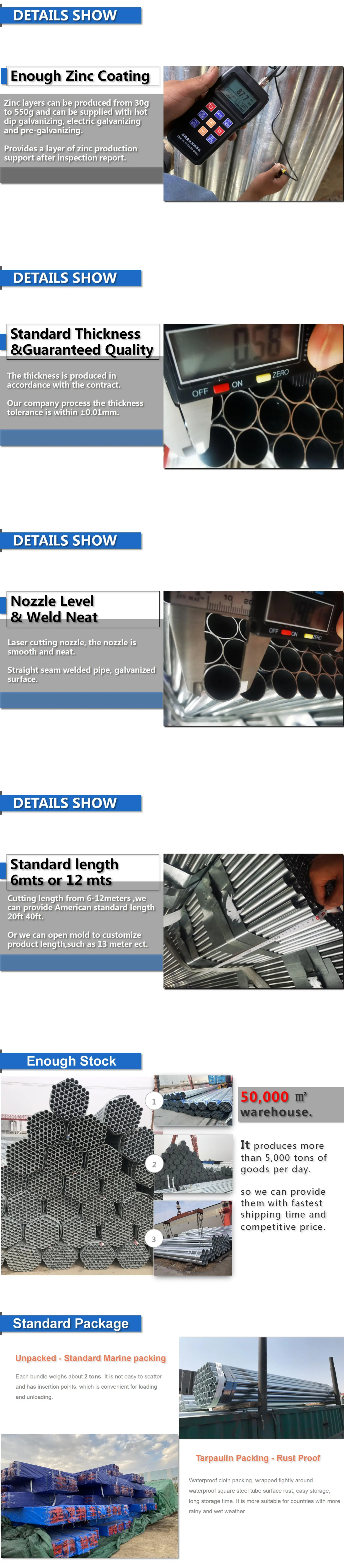

| Zinc Coating | 30-275g/m2 |

| Application | Wide used in various building structures, bridges, vehicles, bracker, machinery etc. |

Details

Galvanized pipe is a common building material with a wide range of uses. However, due to environmental factors, steel pipes are prone to rust, deformation or damage during transportation. Therefore, it is crucial to properly package and transport galvanized pipes. This article will explain how to package galvanized pipes during transportation.

1. Packaging requirements

(1). The surface of the steel pipe should be clean and dry, without oil, dust or other debris.

(2). The steel pipe must be packaged with double-layer plastic-coated paper, with the outer layer covered with plastic cloth with a thickness of not less than 0.5 mm and the inner layer covered with transparent polyethylene plastic film with a thickness of not less than 0.02 mm.

(3). The steel pipe must be marked after packaging. The marking content should include the model, specification, batch number and production date of the steel pipe.

(4). Steel pipes should be classified and packaged according to different categories such as specifications, sizes, and lengths to facilitate loading, unloading and storage.

2. Packaging methods

(1) Before packaging the galvanized pipe, the surface of the pipe should be cleaned to ensure that the surface is clean and dry to avoid corrosion and other problems during transportation.

(2) When packaging galvanized pipes, attention should be paid to the protection of the steel pipes. Red cork plywood should be used to reinforce both ends of the steel pipes to prevent deformation and damage during packaging and transportation.

(3) The packaging materials of galvanized pipes must be moisture-proof, waterproof and rust-proof to ensure that the steel pipes will not be damp or rusted during transportation.

(4) After packaging, galvanized pipes should be protected from moisture and sunlight to avoid prolonged exposure to sunlight or humid environments.

FAQ

Q: Are u a manufacturer?

A: Yes, we are spiral steel tube manufacturer locates in Tianjin city, China

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years gold supplier and accept trade assurance.