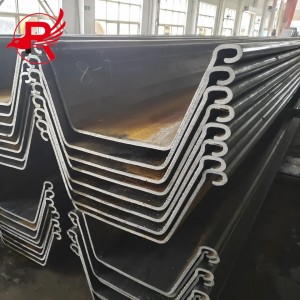

Cold-Formed Steel Sheet Pile U Type 2 Type 3 Steel Sheet Pile

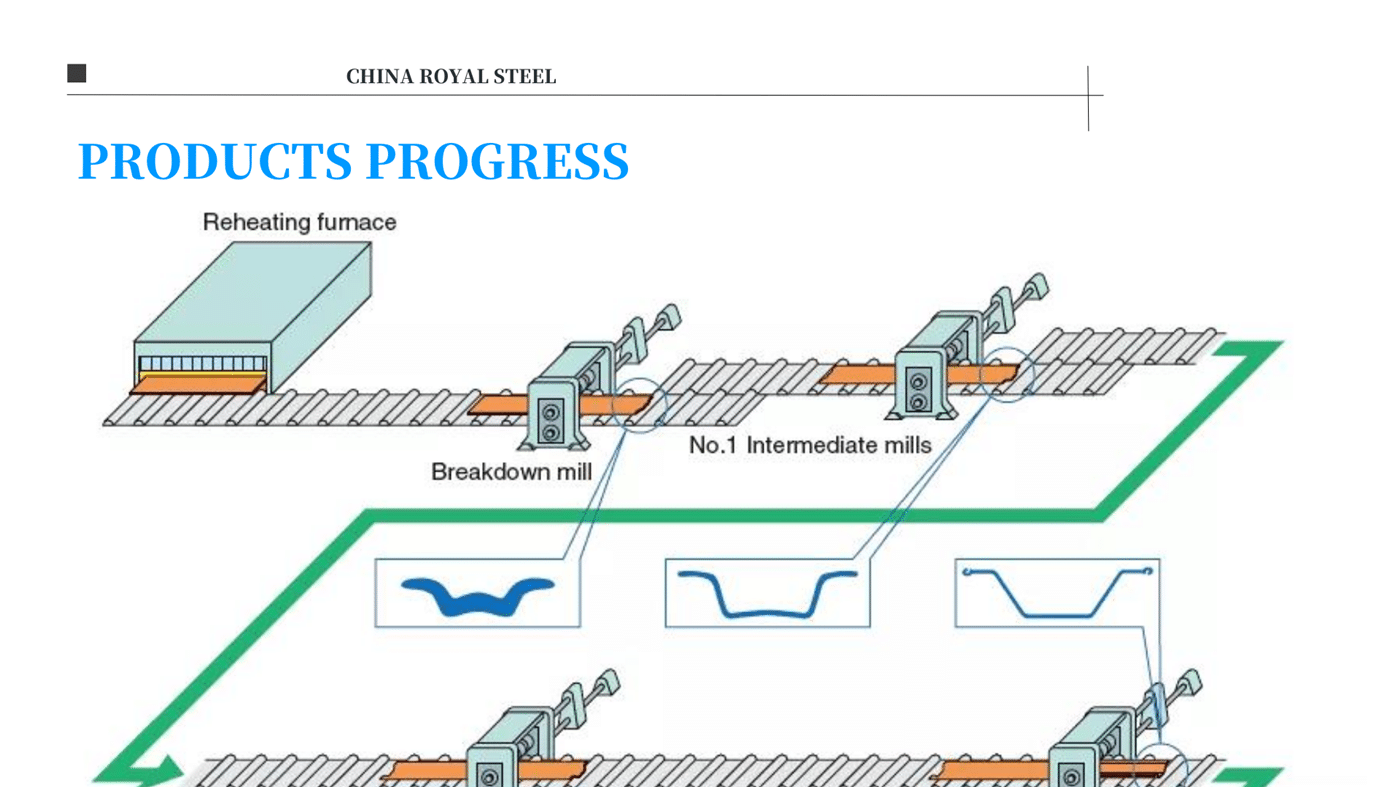

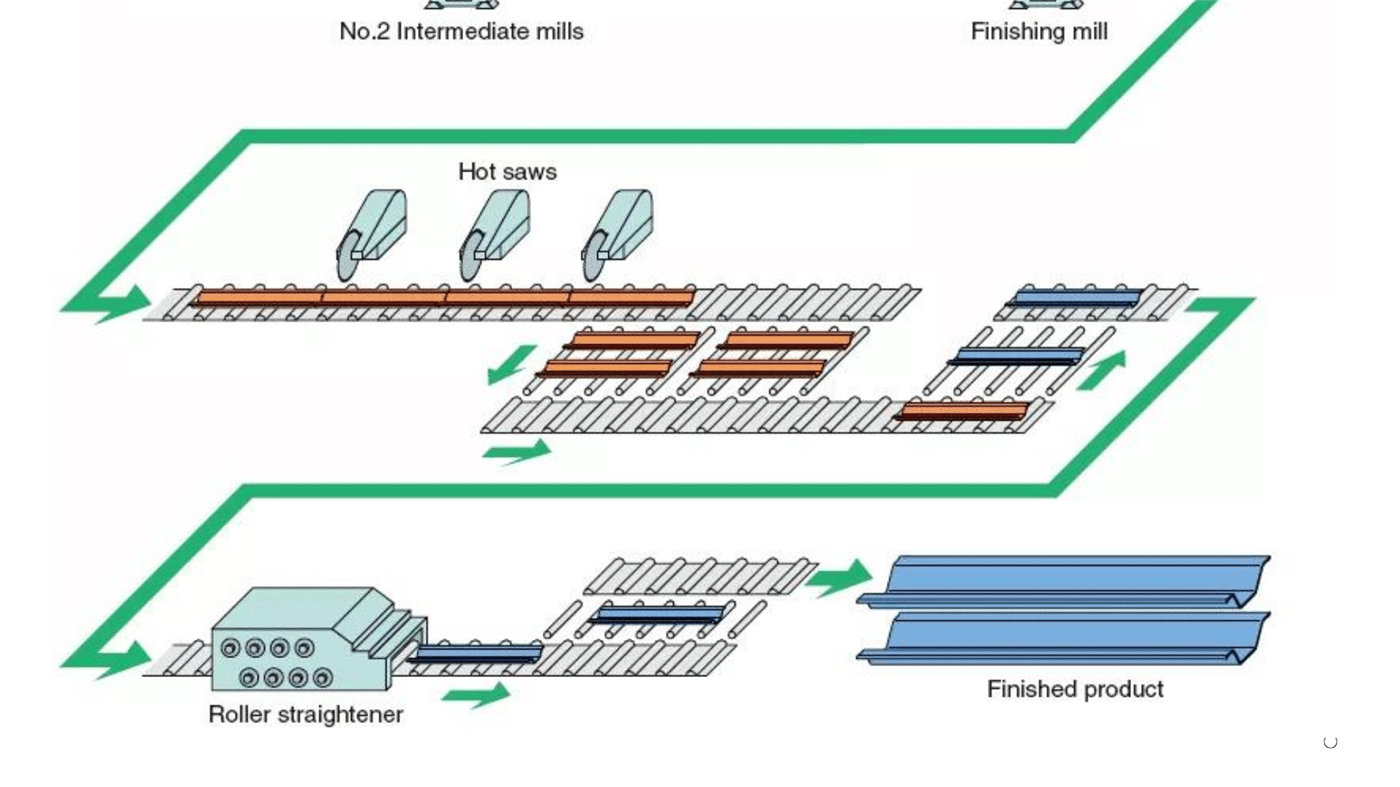

PRODUCT PRODUCTION PROCESS

The cold rolled U shape steel sheet piles production process is as follows:

Preparation of raw materials: To begin with raw materials for U-shaped steel sheet piles, they are hot rolled steel sheets or cold rolled steel sheets.

Plate rolling: The raw steel plate needs to be processed on the plate rolling machine for plate rolling to roll it into a U-shape cross section.

Cold bending: The steel sheet that has been rolled out is cold bend into a U shape with the use of a cold bender or roller bender which roller or steel bender that transform the steel plate into U-shaped cross section.

Cutting: Applying cutting machine to cut the sheet piles to correct size with the length you need.

Welding (option):Coldformed U shaped steel sheet piles is welded as required to make sure the connection is tight and comforming.

Surface treatment: Surface treatment is processed on the finished product, such as rust removal, painting and so on, to enhance the anti-rust effect of the product.

Inspection and Quality Control : Finished products inspection in order to make sure they can meet the related standard and specification.

Package and Delivery: After finishing the product, pack it and ship it to customer or job site.

The above procedures will be changed in terms of the actual production techniques and equipment, but are generally the processes for manufacturing cold-formed U-shape steel sheet piles.

|

Product Name

|

|

|

Steel Grade

|

S275,S355,S390,S430,SY295,SY390,ASTM A690

|

|

Production standard

|

EN10248,EN10249,JIS5528,JIS5523,ASTM

|

|

Delivery time

|

One week,80000 tons in stock

|

|

Certificates

|

ISO9001,ISO14001,ISO18001,CE FPC

|

|

Dimensions

|

Any dimensions,any width x height x thickness

|

|

Length

|

Single length up to over 80m

|

1. We can produce all types of sheet piles,pipe piles and accessories,we can adjust our machines to produce in any width x height x thickness .

2. We can produce single length up to over 100m,and we can do all painting,cutting,welding etc fabrications in factory .

3. Fully internationally certified:ISO9001,ISO14001,ISO18001,CE,SGS,BV etc..

*Send the email to [email protected] to get a quotation for your projects

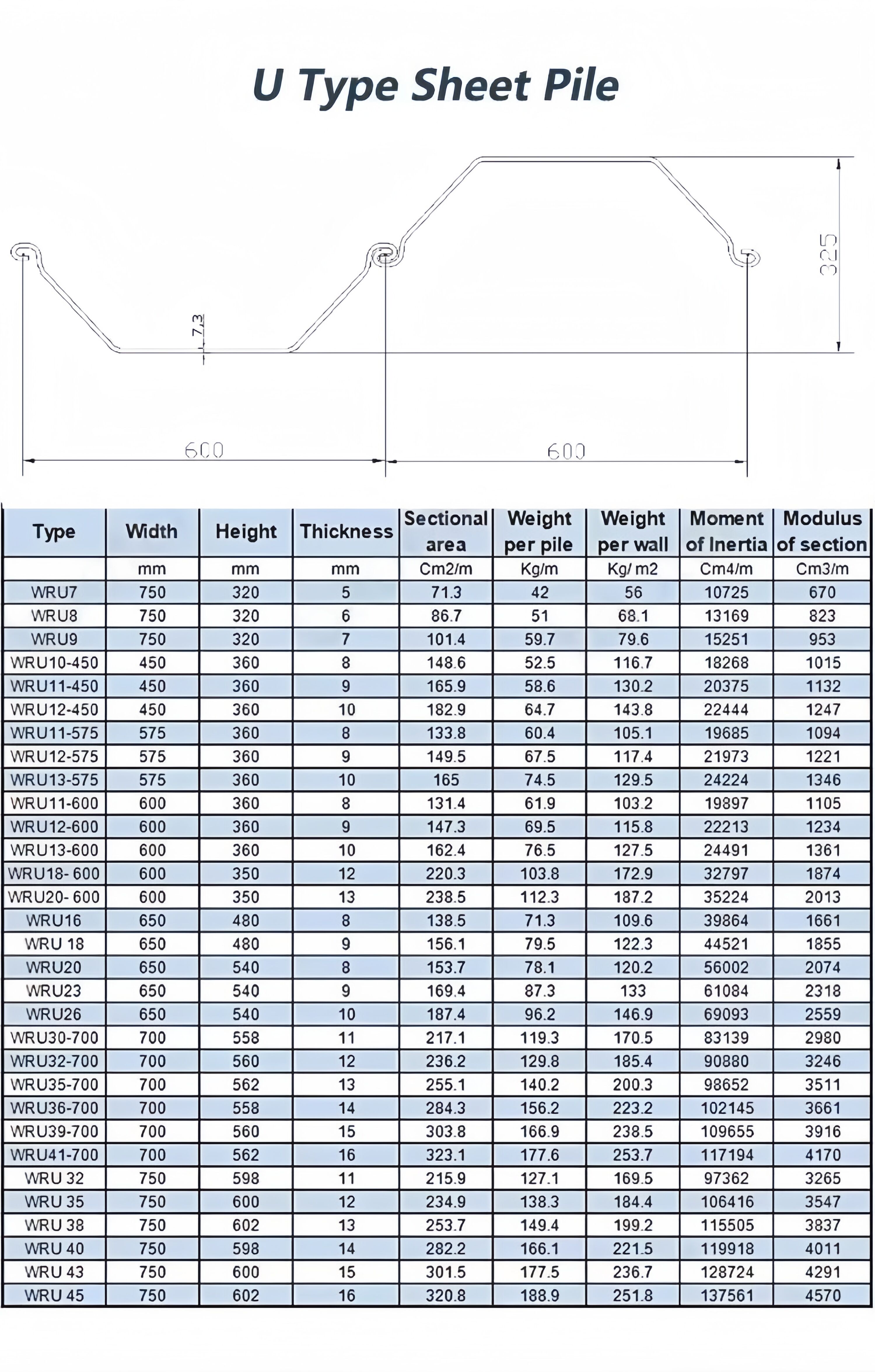

Section Modulus Range

1100-5000cm3/m

Width Range (single)

580-800mm

Thickness Range

5-16mm

Production Standards

BS EN 10249 Part 1 & 2

Steel Grades

SY295, SY390 & S355GP for Type II to Type VIL

S240GP, S275GP, S355GP & S390 for VL506A to VL606K

Length

27.0m maximum

Standard Stock Lengths of 6m, 9m, 12m, 15m

Delivery Options

Single or Pairs

Pairs either loose, welded or crimped

Lifting Hole

By container (11.8m or less) or Break Bulk

Corrosion Protection Coatings

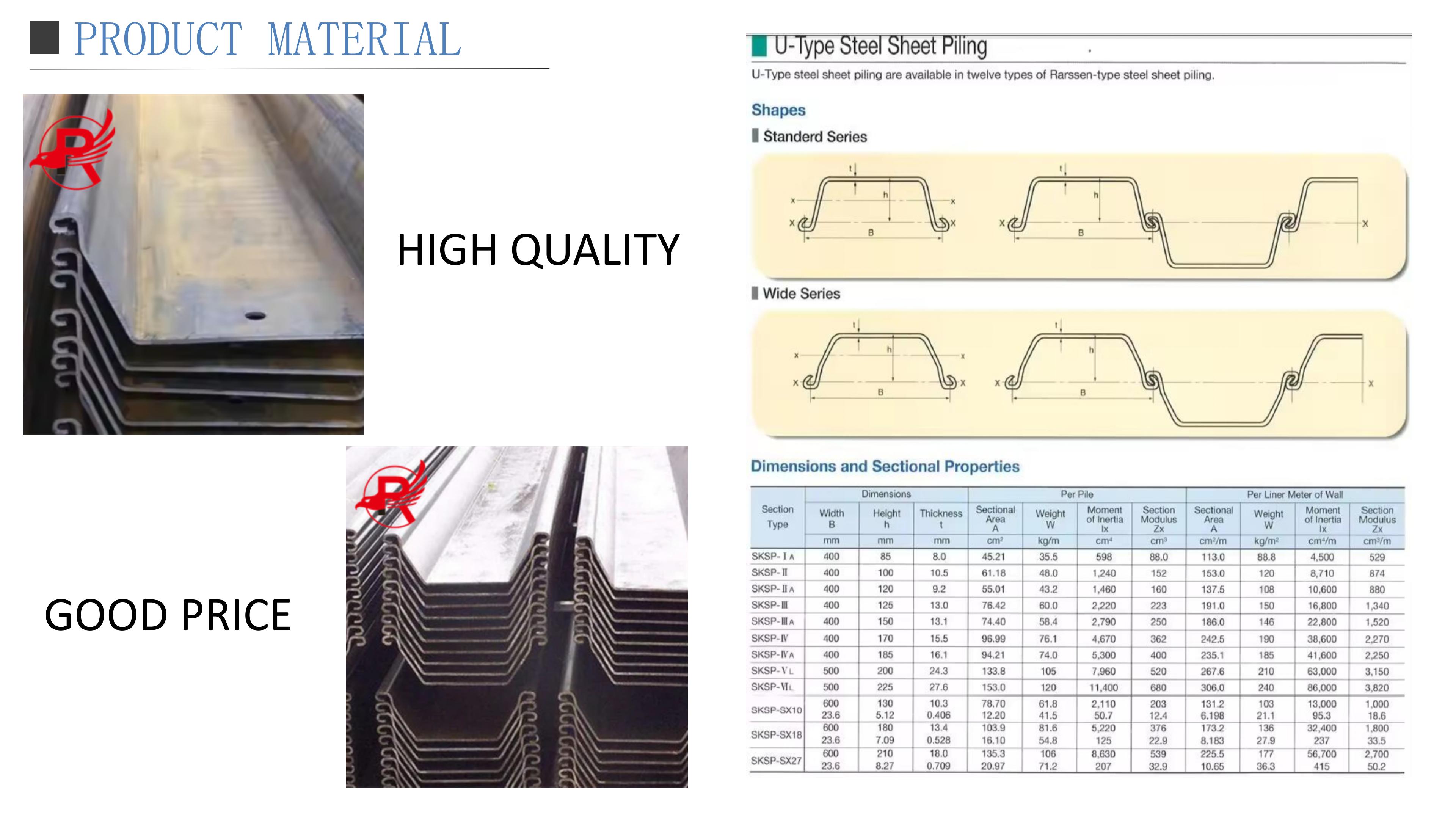

| Section | Width | Height | Thickness | Cross Sectional Area | Weight | Elastic Section Modulus | Moment of Inertia | Coating Area (both sides per pile) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Flange (tf) | Web (tw) | Per Pile | Per Wall | |||||

| mm | mm | mm | mm | cm2/m | kg/m | kg/m2 | cm3/m | cm4/m | m2/m | |

| Type II | 400 | 200 | 10.5 | - | 152.9 | 48 | 120 | 874 | 8,740 | 1.33 |

| Type III | 400 | 250 | 13 | - | 191.1 | 60 | 150 | 1,340 | 16,800 | 1.44 |

| Type IIIA | 400 | 300 | 13.1 | - | 186 | 58.4 | 146 | 1,520 | 22,800 | 1.44 |

| Type IV | 400 | 340 | 15.5 | - | 242 | 76.1 | 190 | 2,270 | 38,600 | 1.61 |

| Type VL | 500 | 400 | 24.3 | - | 267.5 | 105 | 210 | 3,150 | 63,000 | 1.75 |

| Type IIw | 600 | 260 | 10.3 | - | 131.2 | 61.8 | 103 | 1,000 | 13,000 | 1.77 |

| Type IIIw | 600 | 360 | 13.4 | - | 173.2 | 81.6 | 136 | 1,800 | 32,400 | 1.9 |

| Type IVw | 600 | 420 | 18 | - | 225.5 | 106 | 177 | 2,700 | 56,700 | 1.99 |

| Type VIL | 500 | 450 | 27.6 | - | 305.7 | 120 | 240 | 3,820 | 86,000 | 1.82 |

Section Modulus Range

1100-5000cm3/m

Width Range (single)

580-800mm

Thickness Range

5-16mm

Production Standards

BS EN 10249 Part 1 & 2

Steel Grades

SY295, SY390 & S355GP for Type II to Type VIL

S240GP, S275GP, S355GP & S390 for VL506A to VL606K

Length

27.0m maximum

Standard Stock Lengths of 6m, 9m, 12m, 15m

Delivery Options

Single or Pairs

Pairs either loose, welded or crimped

Lifting Hole

By container (11.8m or less) or Break Bulk

Corrosion Protection Coatings

PRODUCT CONSTRUCTION

First, the characteristics of cold formed steel sheet pile

1, Processing is simple :Processing of the steel sheet piles is relatively simple and don’t need too much routines or tools. Due to simple processing such as cutting, welding, mending etc. on the thick steel plate processing of steel sheet piles.

2, Construction is more convenient:Since it’s light and highly flexible, it’s simple and quick to lay down so it can be very convenient to construct. This can even exclude the pollution to environment during the steel sheet pile installation process since the storm water concrete not be cast on site.

3, High strength: Sheet pile is of high strength and stiffness, and can be subjected to large horizontal and axial forces, and its deformation is small. Steel sheet piles are an excellent product to be used in areas where large loads must be supported in deep foundation pits or soil excavation works.

APPLICATION

Advantages of steel pipe pile

1. Wide applicability

Profiles of steel sheet piles can be combined with anchor systems in a variety of ways due to the broad application possibilities of steel sheet pile. It is well adapted to soil and water, and is applicable to projects in construction, shipyards, and wharves where both are present, and may also be employed to sustain deep foundation pits as well as in metal storage tanks.

2, with good corrosion resistance

Because sheet piling are made of high-strength steel sheets, they have good corrosion resistance and can be used in a variety of harsh environments.

3. Long life

The cold formed steel sheet pile has a long service life, can adapt to various climatic conditions and external environmental changes, and has excellent rust prevention function.

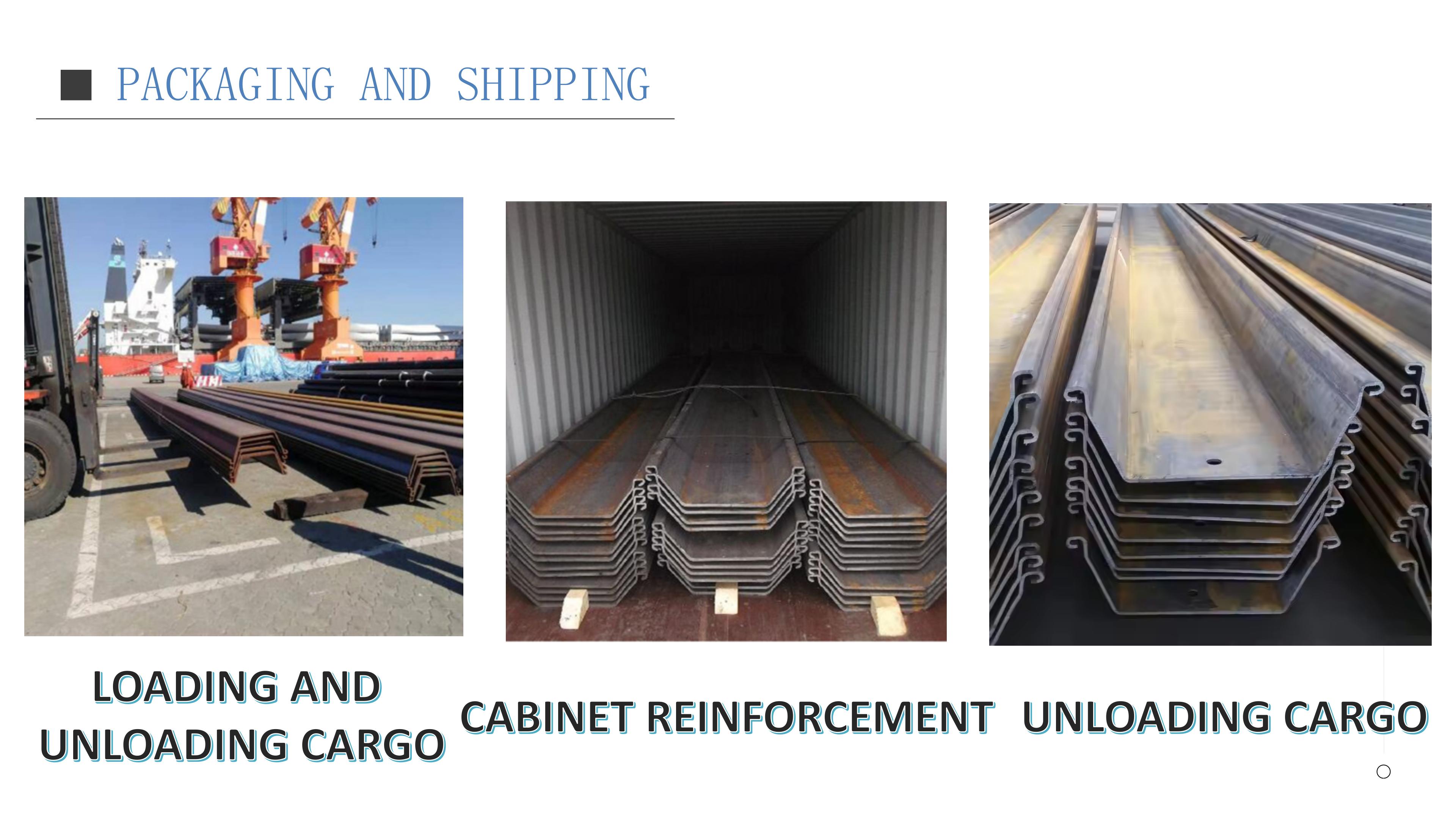

PACKAGING AND SHIPPING

Q235 Steel Sheet Pile should be placed in a sunshade and rainproof place during storage. Long-term exposure to sunlight and rain, light will make the surface of the steel sheet pile appearance changes, heavy may lead to rust, seriously affecting the service life and effect. Therefore, be sure to choose a covered storage place, or use rainproof and sunshade cloth to cover the steel pipe pile construction

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.