China Prefab Strut Steel Structures Building Steels Frame

The steel structure has good seismic, wind and fire resistance performance, which can ensure the safety and reliability of the building.

In the field of tower, steel market is widely used in tower, TV tower, antenna tower, chimney and other structural systems. Steel structure has the advantages of high strength, light weight and fast construction speed, which makes it widely used in the field of tower.

*Send the email to [email protected] to get a quotation for your projects

| Product name: | Steel Building Metal Structure |

| Types of steel: | Q235B ,Q345B |

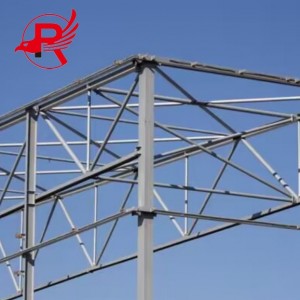

| Main frame : | H-shape steel beam |

| Purlin : | C,Z - shape steel purlin |

| Roof and wall : | 1.corrugated steel sheet ;

2.rock wool sandwich panels ;

3.EPS sandwich panels ; 4.glass wool sandwich panels |

| Door: | 1.Rolling gate

2.Sliding door

|

| Window: | PVC steel or aluminum alloy |

| Down spout : | Round pvc pipe |

| Application : | All kinds of industrial workshop ,warehouse ,high-rise building,metal building home |

PRODUCT PRODUCTION PROCESS

ADVANTAGE

There's also a heat-bridge-resistant light steel frame buildings system. While the building itself isn't energy-efficient, this technology utilizes ingenious special connectors to address the problem of internal heat and cold bridges. The small truss structure allows cables and water pipes to be routed through the walls for installation, making renovation easier.

Advantages:

Steel component systems offer comprehensive advantages, including light weight, factory-fabricated construction, quick installation, a short construction period, excellent seismic performance, rapid investment payback, and reduced environmental pollution. Compared to reinforced concrete structures, they offer these three unique advantages. Consequently, steel components are widely and rationally used in construction projects worldwide, especially in developed countries and regions.

Bearing Capacity:

Practice has shown that the greater the load, the greater the deformation of a steel component. However, when the load is excessive, steel components can fracture or undergo severe and significant plastic deformation, compromising the proper functioning of the structure. To ensure the proper functioning of engineering materials and structures under load, each steel component must possess sufficient bearing capacity, also known as bearing capacity. Bearing capacity is primarily measured by sufficient strength, stiffness, and stability.

Sufficient Strength: Strength refers to the ability of a steel component to resist damage (fracture or permanent deformation). That is, under load, no yield failure or fracture occurs, ensuring safe and reliable operation. Strength is a basic requirement that all load-bearing components must meet, and therefore it is also the focus of learning.

DEPOSIT

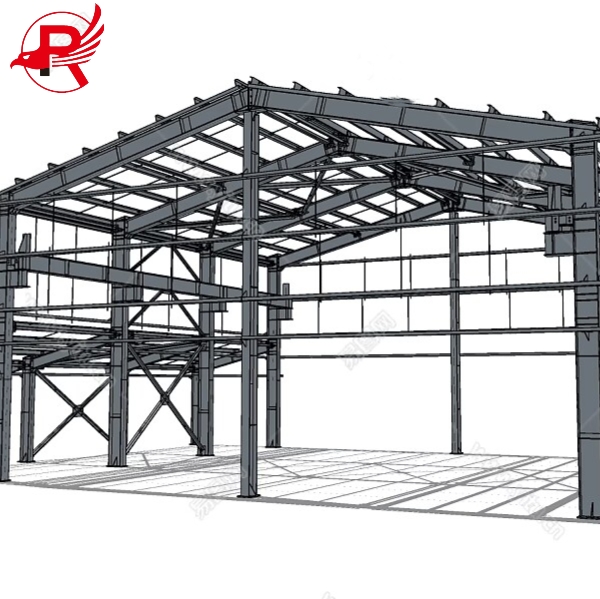

The steel manufacturing building is a new type of industrial building. Its basic component is the steel structure skeleton system, which mainly consists of the following three parts:

1. Main Frame: This includes components such as columns, beams, and bridges. They are the core of the steel structure and bear the weight and load of the entire factory building.

2. Roof System: The roof is a crucial component of a steel structure factory building. Typically constructed from color-coated steel sheets, the roof offers lightweight, high strength, waterproofing, and thermal insulation.

3. Wall System: The wall is typically constructed from color-coated steel sheets or sandwich panels. It not only provides insulation, fire resistance, and flame retardancy, but also enhances the building's aesthetics.

PROJECT

Our company often exports steel structure products to the Americas and Southeast Asian countries. We participated in one of the projects in the Americas with a total area of approximately 543,000 square meters and a total use of approximately 20,000 tons of steel. After the project is completed, it will become a steel structure complex integrating buildings designed, living, office, education and tourism.

PRODUCT INSPECTION

1. Material testing

The quality of Steel Structure Buildings materials directly affects the quality and safety of the entire project, so material testing is one of the most basic and important links in the steel structure testing project. The main testing contents include the thickness, size, weight, chemical composition, mechanical properties, etc. of the steel plate. In addition, more stringent testing is required for some special-purpose steels, such as weathering steel, refractory steel, etc.

2. Component Testing

Component testing primarily encompasses two aspects: the component's geometric dimensions and shape; and its mechanical properties. Geometric dimensions and shape testing primarily utilizes tools such as rulers and calipers, while mechanical property testing requires more complex tests, such as tensile, compression, and bending tests, to determine component performance indicators such as strength, stiffness, and stability.

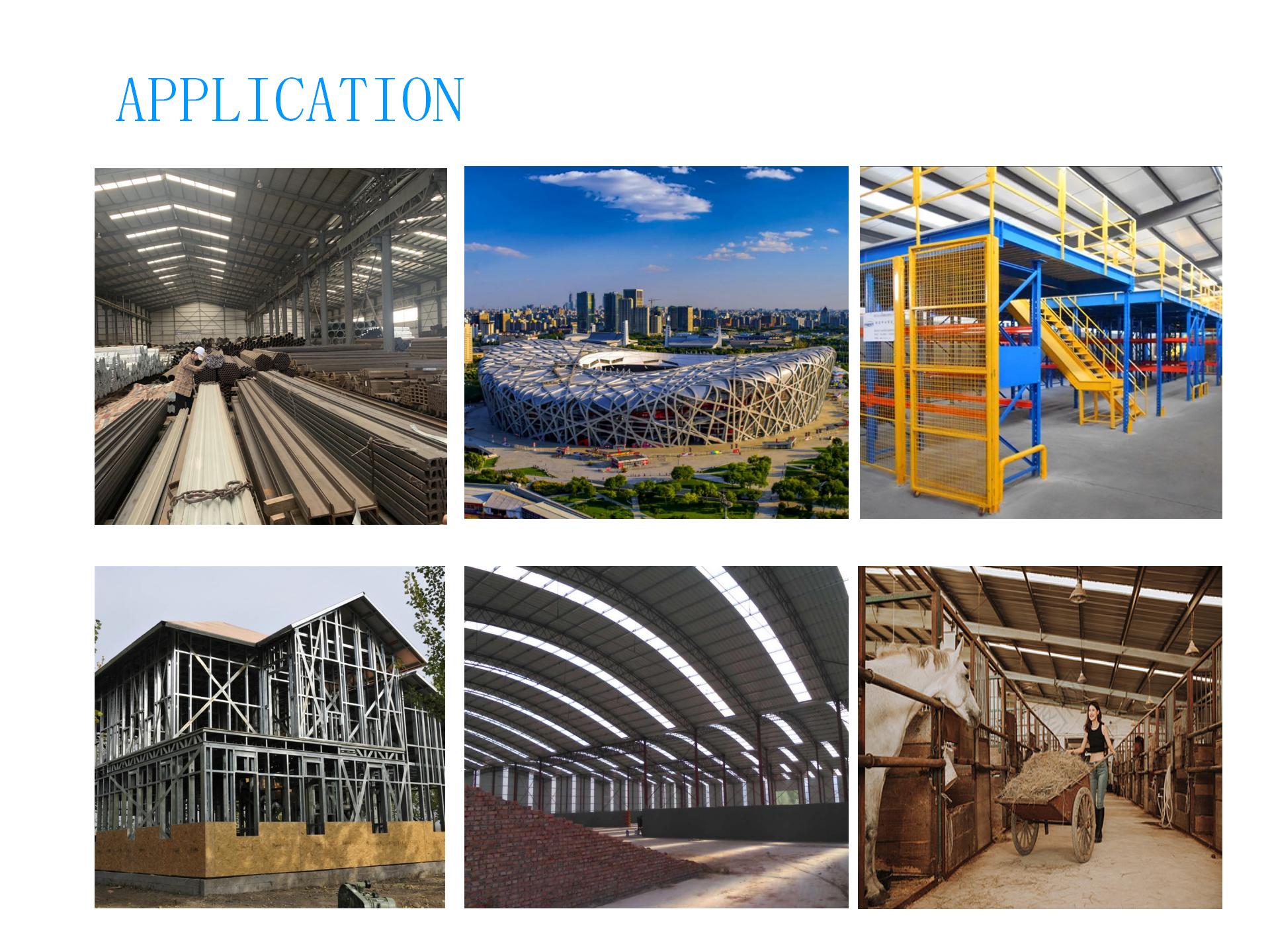

APPLICATION

Steel Structure Metal Building is a structure built with steel as the main material. The more common steel structure designs in life include Light Steel Structure House, Steel Structure School Building, Steel Structure Warehouse, Steel Structure Shed, Steel Structure Car Garage and Steel Structure For Workshop.This structure has been widely used in various fields such as construction, bridges, railways, vehicles, ships, machinery manufacturing and petrochemical industry. The following are the main scope of application of steel structures:

Construction field: Steel structures have been widely used in modern buildings, including high-rise buildings, industrial plants, commercial buildings, stadiums, exhibition halls, stations, bridges, etc. Steel structures have the advantages of light weight, high strength, fast construction speed, and good seismic resistance. They can meet the requirements of modern buildings for structural safety, economy, and environmental protection.

Bridge engineering: Steel structures have been widely used in bridge engineering, including road bridges, railway bridges, pedestrian bridges, cable-stayed bridges, suspension bridges, etc. Steel structures have the advantages of light weight, high strength, convenient construction, and good durability, and can meet the requirements of bridge engineering for structural safety and economy.

Machinery manufacturing field: Steel structures have been widely used in the field of machinery manufacturing, including various machine tools, presses, industrial furnaces, rolling mills, cranes, compressors, transmission equipment, etc. Steel structures have the advantages of high strength, good rigidity, and easy processing, and can meet the requirements for equipment accuracy and stability in the mechanical manufacturing field.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT