China Supplier Hot dip Galvanized C Strut Channel Prices

Galvanized C-Channel steel is a profile formed by hot-dip galvanizing (HDG) or electrogalvanizing ordinary hot-rolled or cold-formed C-shaped steel (with a "C"-shaped groove structure) to form a protective zinc layer. It combines the "lightweight and high rigidity" structural advantages of C-shaped steel with the "strong corrosion resistance" of the galvanized layer. It is one of the core profiles that can replace traditional uncoated steel and reduce maintenance costs in fields such as construction, machinery, and logistics.

PRODUCT SIZE

| Material | Carbon steel / SS304 /SS316 / Aluminum |

| Surface Treatment | GI,HDG(Hot Dipped Dalvanized ),powder coating (Black,Green,White,Grey,Blue)etc. |

| Lengths | Either 10FT or 20FT

or cut into the length according to Customer's Requirements |

| Thickness | 1.0mm,,1.2mm1.5mm, 1.8mm,2.0mm, 2.3mm,2.5mm |

| Holes | 12*30mm/41*28mm or according to Customer's Requirements |

| Style | Plain or Slotted or back to back |

| Type | (1)Tapered Flange Channel (2)Parallel Flange Channel |

| Packaging | Standard Seaworthy Package:In Bundles and fasten with steel strips

or packed with braided tape outside |

| No. | Size | Thickness | Type | Surface

Treatment |

||

| mm | inch | mm | Gauge | |||

| A | 41x21 | 1-5/8x13/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| B | 41x25 | 1-5/8x1" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| C | 41x41 | 1-5/8x1-5/8" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| D | 41x62 | 1-5/8x2-7/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| E | 41x82 | 1-5/8x3-1/4" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

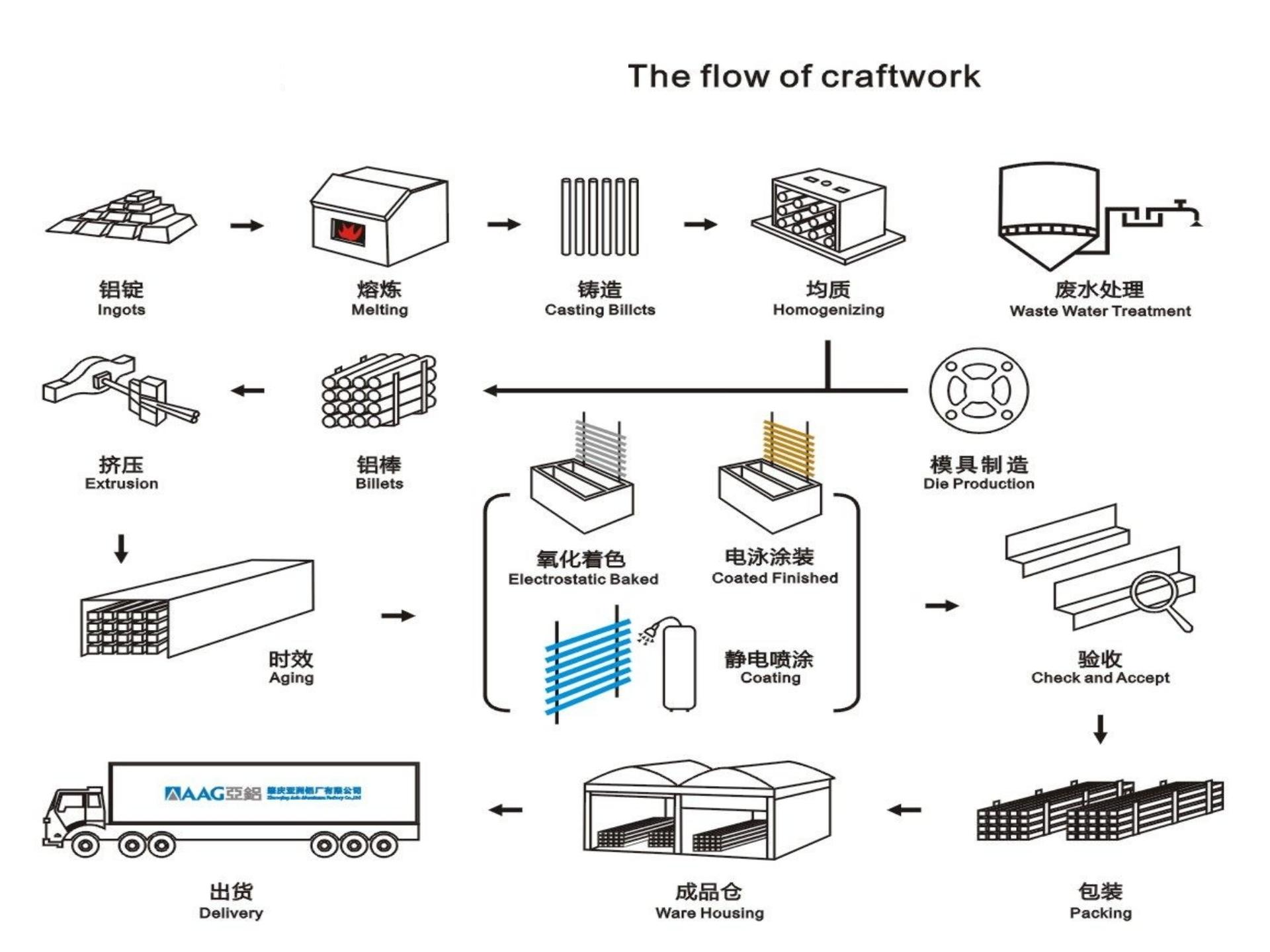

PRODUCT PRODUCTION PROCESS

ADVANTAGE

1. Improve photovoltaic power generation efficiency

The absorption efficiency of photovoltaic modules is related to its tilt angle and orientation. Through appropriate bracket design,GI C channel the tilt angle and orientation of the photovoltaic modules can be optimized, thereby maximizing the absorption of solar energy and improving photovoltaic power generation efficiency.

2. Extend the life of photovoltaic modules

The function of the bracket is to protect the steel c channel sizes modules to withstand 30 years of damage from sunlight, corrosion, strong winds, etc. Photovoltaic modules are installed on brackets to avoid direct contact with the ground or other unstable foundations, thereby reducing shaking and looseness caused by natural factors such as wind and rain, and ensuring the stability of steel c channel. Photovoltaic brackets can place photovoltaic modules in a position that is easier to maintain, making cleaning, inspection and replacement easier, thereby extending the service life of photovoltaic modules. Photovoltaic brackets can also prevent photovoltaic modules from being hit by external forces, reducing mechanical damage, thereby extending the service life of c channel metal

3. Convenient maintenance and management

Since the photovoltaic bracket can arrange the photovoltaic modules more regularly, it can be more convenient for maintenance and management. If something breaks down or needs to be serviced, technicians can find the problem faster and make removal and replacement easier.

4. Save land space

By combining photovoltaic modules and fishing rafts, the ocean space is utilized to the maximum extent without occupying additional land resources. Setting up photovoltaic modules at sea can avoid problems such as land reclamation and environmental damage caused by land photovoltaic power plants, and at the same time reduce the impact of human activities at sea on marine ecology.

5. Environmental protection and energy saving

Photovoltaic brackets are usually made of renewable materials and are environmentally friendly and energy-saving. And photovoltaic modules can directly generate electricity by converting solar energy, without requiring any fuel, producing no pollutants, and having no negative impact on the environment.

APPLICATION

C-section steel is widely used in the construction industry. Its strength and durability make it a top choice for building support structures such as beams, purlins, and frames. Its corrosion resistance makes it suitable for both indoor and outdoor applications, ensuring longevity and reliability.

Another common use for C-section steel is in electrical installations and HVAC systems. Known as "support C-section steel," it provides a safe and convenient installation solution for conduit, pipes, and cable trays. Its simple design makes it easy to install, saving time and effort.

In construction and industrial projects, efficiency and reliability are crucial. Support channels are an often-overlooked solution that play a vital role in ensuring structural integrity and flexibility. This widely used component, also known as a steel channel or C-channel, has a wide range of applications across various industries. In this blog post, we will explore how support channels contribute to the success of construction, electrical, HVAC, and manufacturing projects.

1. Construction Industry:

The construction industry relies heavily on support channels for their versatility and strength. These components are essential for supporting heavy loads, providing stability, and building modular structures. Support channels are widely used in the structural framework of buildings, bridges, and other infrastructure projects. They also serve as a framework for installing conduit and wiring, facilitating maintenance.

2. Electrical Applications:

Support channels are an ideal platform for electrical installations. They ensure proper cable management by securely suspending conduit, tray systems, and wiring. Furthermore, their design allows for future expansion and easy modification, reducing the time and effort required for updates or repairs. Their ability to accommodate additional electrical components allows them to easily adapt to evolving electrical systems.

3. HVAC Systems:

Support channels are indispensable in the heating, ventilation, and air conditioning (HVAC) industry. They provide an excellent support system for installing ductwork, HVAC units, and auxiliary equipment. Their durability ensures the stability and safety of HVAC systems. Their efficient distribution of conditioned air makes them a vital component in maintaining indoor air quality and regulating temperature.

4. Manufacturing:

The versatility of support channels offers significant benefits to the manufacturing industry. They are widely used to create efficient workstations, assembly lines, and conveyor systems. Because support channels are easily adjustable and adaptable, manufacturers can quickly reconfigure their production setups, saving time and costs. Support troughs also facilitate the installation of machinery, equipment, and automation components, improving productivity and workflow efficiency.

5. Custom Applications:

Beyond the specific industries mentioned above, support troughs can be used in a variety of other applications. Their adaptability enables countless creative uses, such as exhibition displays, retail shelving, and vehicle racking systems. The ability to attach accessories such as brackets, clamps, and fasteners makes support troughs a versatile solution suitable for countless custom configurations.

PRODUCT INSPECTION

C channel steel offers numerous advantages, ranging from its affordability to its versatility in various industrial applications. By opting for c channel steel, you can ensure the durability and stability of your project while staying within budget. Take advantage of the expertise of an industrial metal supplier to explore the wide range of options available and kickstart your industrial project today!

One of the significant advantages of using c channel steel is its affordability. Compared to other metal options, c channel steel prices are often much more competitive, making it a cost-effective choice for large-scale projects. Industrial metal suppliers offer a wide range of c channel steel options, allowing you to find the perfect fit for your specific requirements.

PROJECT

Royal Group is a China Galvanized Steel C Channel Supplier.Our company participated in South America's largest solar energy development project, providing support and solution design. We supplied 15,000 tons of photovoltaic support systems for the project. These systems utilize emerging domestic technologies, contributing to the development of the South American photovoltaic industry and improving the lives of local residents. The photovoltaic support system project includes a 6MW photovoltaic power station and a 5MW/2.5h battery energy storage station, generating approximately 1,200 kWh of electricity annually. The system boasts excellent photovoltaic conversion capabilities.

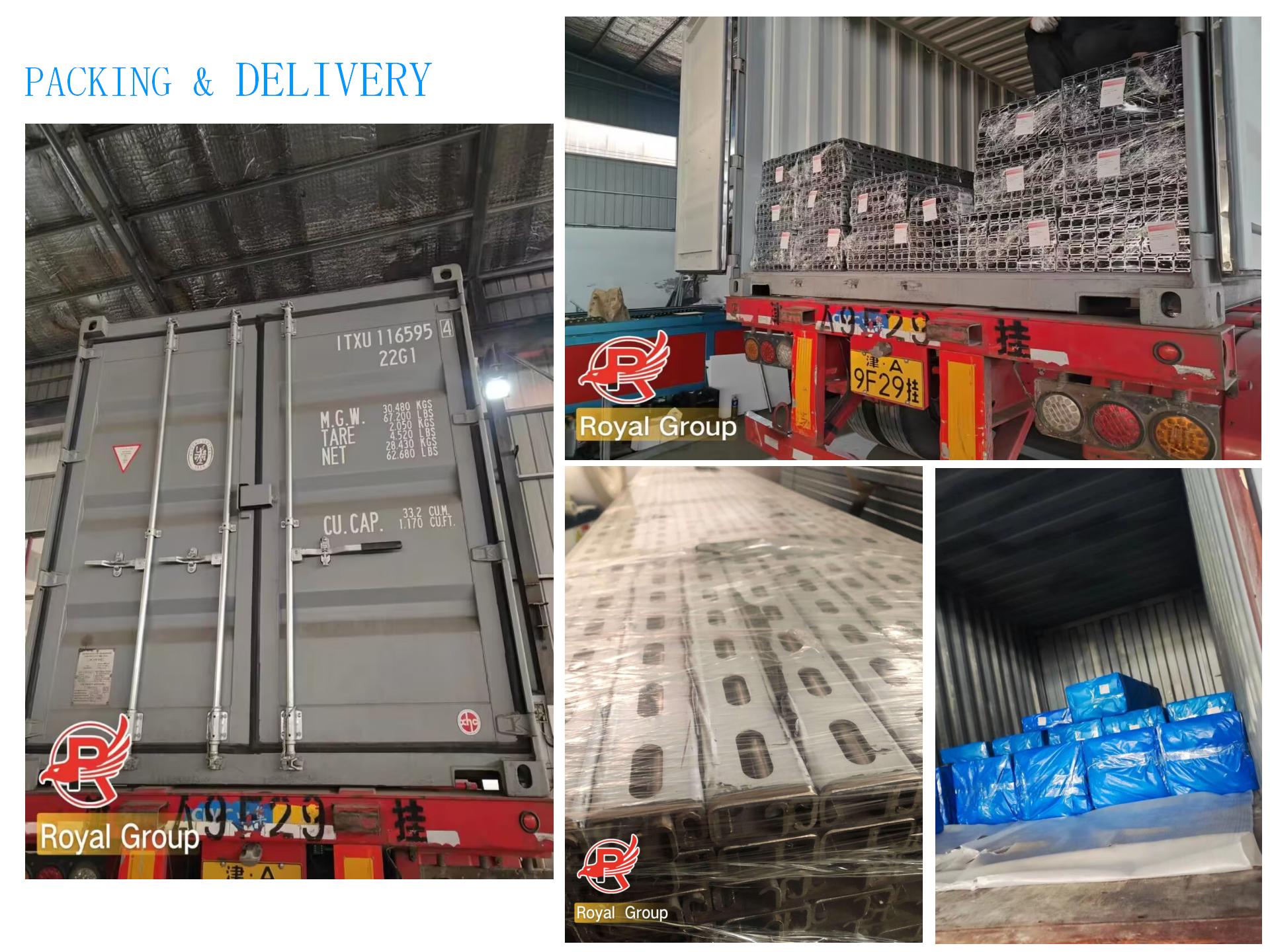

PACKAGING AND SHIPPING

Properly packaging and shipping strut channels is a crucial aspect of any manufacturer or distributor's operations. By adopting best practices, utilizing innovative technologies, and selecting reliable carriers, businesses can protect their products, streamline operations, and enhance customer satisfaction – ultimately paving the way for success in the competitive market of industrial materials.

Packaging:

We pack the products in bundles. A bundle of 500-600kg. A small cabinet weighs 19 tons.The outer layer will be wrapped with plastic film.

Shipping:

Choose a suitable mode of transportation: Depending on the quantity and weight of the Strut Channel, select the appropriate mode of transportation, such as flatbed trucks, containers, or ships. Consider factors like distance, time, cost, and any regulatory requirements for transportation.

Use appropriate lifting equipment: To load and unload the Strut Channel, use suitable lifting equipment such as cranes, forklifts, or loaders. Ensure that the equipment used has sufficient capacity to handle the weight of the sheet piles safely.

Secure the load: Properly secure the packaged stack of Strut Channel on the transportation vehicle using strapping, bracing, or other suitable means to prevent shifting, sliding, or falling during transit.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.