High Strength Sy295 Sy390 SS400 400*100*10.5mm U Steel Sheet Pile for Building

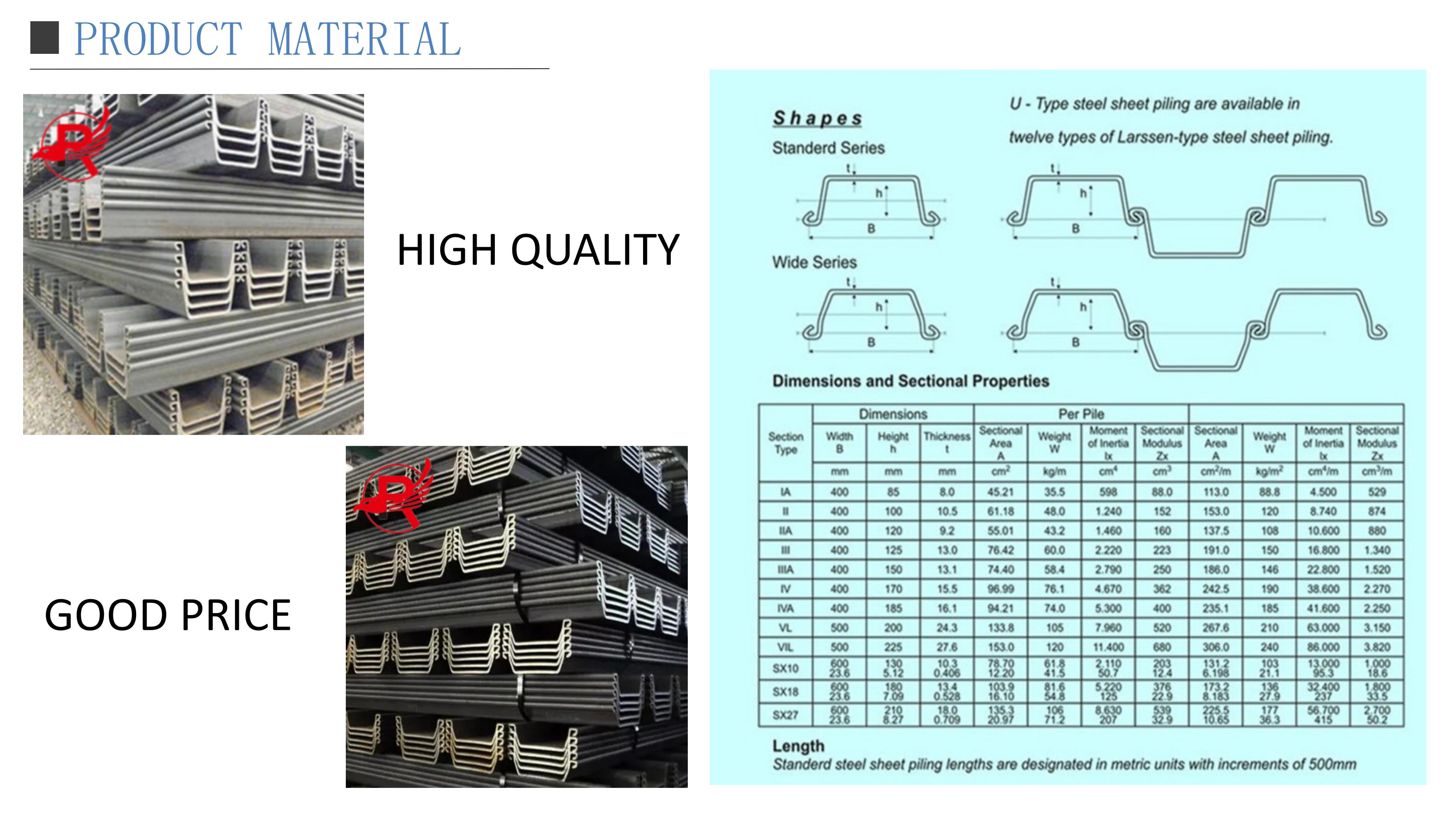

| Section | Width | Height | Thickness | Cross Sectional Area | Weight | Elastic Section Modulus | Moment of Inertia | Coating Area (both sides per pile) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Flange (tf) | Web (tw) | Per Pile | Per Wall | |||||

| mm | mm | mm | mm | cm2/m | kg/m | kg/m2 | cm3/m | cm4/m | m2/m | |

| Type II | 400 | 200 | 10.5 | - | 152.9 | 48 | 120 | 874 | 8,740 | 1.33 |

| Type III | 400 | 250 | 13 | - | 191.1 | 60 | 150 | 1,340 | 16,800 | 1.44 |

| Type IIIA | 400 | 300 | 13.1 | - | 186 | 58.4 | 146 | 1,520 | 22,800 | 1.44 |

| Type IV | 400 | 340 | 15.5 | - | 242 | 76.1 | 190 | 2,270 | 38,600 | 1.61 |

| Type VL | 500 | 400 | 24.3 | - | 267.5 | 105 | 210 | 3,150 | 63,000 | 1.75 |

| Type IIw | 600 | 260 | 10.3 | - | 131.2 | 61.8 | 103 | 1,000 | 13,000 | 1.77 |

| Type IIIw | 600 | 360 | 13.4 | - | 173.2 | 81.6 | 136 | 1,800 | 32,400 | 1.9 |

| Type IVw | 600 | 420 | 18 | - | 225.5 | 106 | 177 | 2,700 | 56,700 | 1.99 |

| Type VIL | 500 | 450 | 27.6 | - | 305.7 | 120 | 240 | 3,820 | 86,000 | 1.82 |

*Send the email to [email protected] to get a quotation for your projects

Section Modulus Range

1100-5000cm3/m

Width Range (single)

580-800mm

Thickness Range

5-16mm

Production Standards

BS EN 10249 Part 1 & 2

Steel Grades

SY295, SY390 & S355GP for Type II to Type VIL

S240GP, S275GP, S355GP & S390 for VL506A to VL606K

Length

27.0m maximum

Standard Stock Lengths of 6m, 9m, 12m, 15m

Delivery Options

Single or Pairs

Pairs either loose, welded or crimped

Lifting Hole

By container (11.8m or less) or Break Bulk

Corrosion Protection Coatings

TECHNICAL PARAMETERS

PRODUCTION PROCESS

PRODUCT SIZE

|

SPECIFICATIONS FOR SHEET PILE |

|

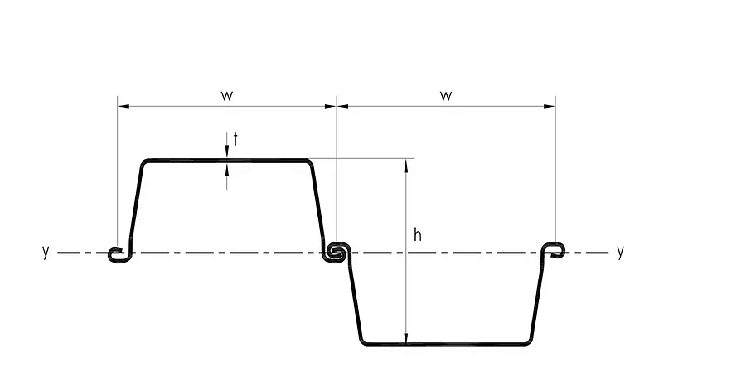

| 1. Size | 1) 400*100 - 600*210MM |

| 2)Wall Thickness:10.5-27.6MM | |

| 3) U type sheet pile | |

| 2. Standard: | JIS A5523, JIS A5528 |

| 3.Material | SY295, SY390, S355 |

| 4. Location of our factory | Shandong,China |

| 5. Usage: | 1)earth-retaining wall |

| 2)structure construction | |

| 3)fence | |

| 6. Coating: | 1) Bared2) Black Painted (varnish coating)3) galvanized |

| 7. Technique: | hot rolled |

| 8. Type: | U type sheet pile |

| 9. Section Shape: | U |

| 10. Inspection: | Client inspection or inspection by 3rd party. |

| 11. Delivery: | Container, Bulk Vessel. |

| 12. About Our Quality: | 1) No damage, no bent2) Free for oiled&marking3) All goods can be checked by third party inspection before shipment |

*Send the email to [email protected] to get a quotation for your projects

FEATURES

High degree of standardization and stable quality.

Manufactured in accordance with Japanese Industrial Standards JIS A 5523/JIS A 5528, these piles have standardized dimensions, strength, and moment of inertia, ensuring strict quality control and high reliability.

Optimized cross-sectional design for an excellent strength-to-weight ratio.

Japanese standard steel sheet piles utilize scientifically designed U-shaped and Z-shaped cross sections, ensuring strength while reducing weight and improving construction efficiency and cost-effectiveness.

Precise interlocking structure and excellent water-stopping performance.

High interlocking precision ensures a tight connection between piles, providing excellent anti-seepage and anti-leakage performance, making them suitable for river channels, harbors, and underground projects.

Strong construction adaptability.

Compatible with a variety of piling equipment (vibratory hammers, hydraulic hammers, static presses, etc.), they can be used in various geological conditions, including soft soil, sandy soil, and backfill.

Reusable and environmentally sustainable.

After dismantling, they can be reused multiple times, reducing resource waste and meeting the requirements of modern green building and sustainable development.

Representative Material Grades

Common materials include SY295 and SY390, each corresponding to a different strength level to meet various engineering requirements.

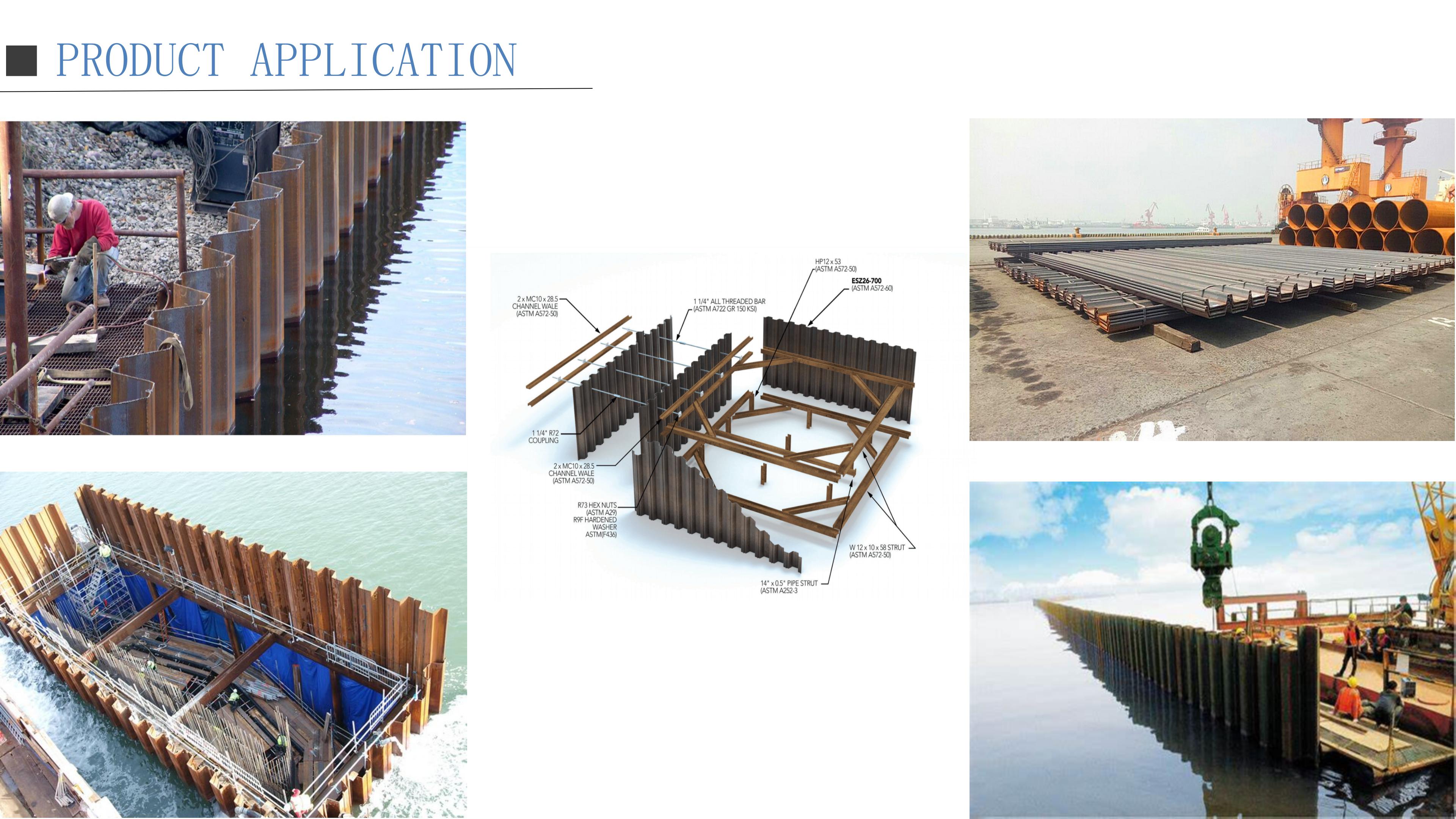

APPLICATION

Harbor & Wharf Construction

Used for constructing structures such as quay walls, docks, revetments, and docks to ensure the stability and safety of coastal and waterside facilities.

River & Flood Control Projects

Used as retaining, anti-seepage, or bank protection structures, they prevent river erosion and bank collapse, enhancing flood control capabilities.

Foundation & Excavation Support

Widely used in retaining structures for projects such as subways, underground garages, and bridge foundations, providing support and water-stopping functions.

Bridge & Road Construction

Used for structures such as bridge abutments, slope protection, and temporary passageways to ensure construction safety and foundation stability.

Marine & Hydraulic Works

Used in seawalls, revetments, water intakes, pumping stations, and other facilities to protect against wave impact and water erosion.

Temporary & Emergency Projects

For emergency reinforcement, river channel emergency protection, and temporary cofferdams, these structures can be quickly installed and removed, offering flexibility and convenience.

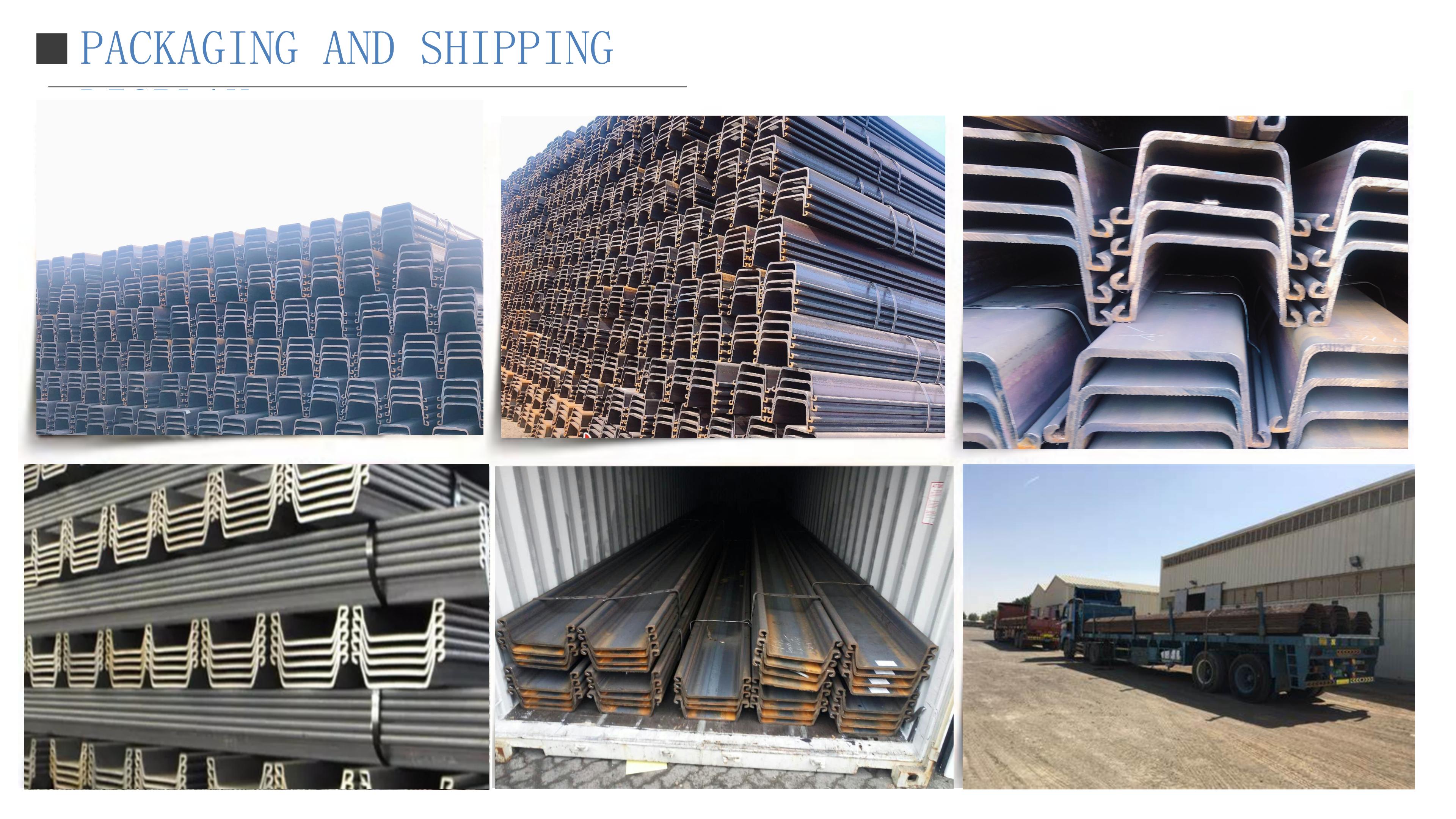

PACKAGING AND SHIPPING

Packaging:

Stack the sheet pile u type securely: Arrange the U-shaped sheet piles in a neat and stable stack, ensuring that they are aligned properly to prevent any instability. Use strapping or banding to secure the stack and prevent shifting during transportation.

Use protective packaging: Wrap the sheet piles in moisture-proof material (such as plastic or waterproof paper) to protect them from water, humidity, and other environmental factors. This helps prevent rust and corrosion.

Transportation:

Choose transport: Select a suitable method (flatbed truck, container, or ship) based on quantity, weight, distance, time, cost, and regulations.

Use proper lifting equipment: Load and unload with cranes, forklifts, or loaders capable of handling the weight safely.

Secure the load: Fasten the sheet piles with straps or braces to prevent shifting or falling during transport.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

When a customer wishes to visit a product, the following steps can usually be arranged:

-

1. Schedule an Appointment

Customers can contact our sales representatives to arrange a convenient time and location for their visit.2. Guided Factory Tour

Our professional team provides a comprehensive tour of the production facilities, highlighting advanced technologies, manufacturing processes, and strict quality control systems.3. Product Showcase

Visitors can view products at different stages of production to better understand our craftsmanship, materials, and quality standards.4. Technical Consultation

Our experts are available to answer all inquiries with detailed explanations about specifications, performance, and application solutions.5. Sample Experience

Upon request, product samples can be provided for hands-on evaluation, allowing customers to experience the quality and performance firsthand.6. Follow-Up Service

After the visit, our team follows up to gather feedback, provide additional technical support, and explore potential cooperation opportunities.

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.