Hot Rolled Carbon Steel Round Bar GB Standard Round Bar 20# 45# Round Bar Price

The details of a carbon structure steel round bar typically include the dimensions, such as diameter and length, as well as the specific grade or specification. Carbon steel round bars, such as AISI 1018, 1045, and 1144, are characterized by their properties and chemical composition. Good strength, machinability, and weldability make these products suitable for machining, manufacturing, and building applications. Other considerations could be surface finish, dimensional tolerances and standards e.g. ASTM or SAE.

PRODUCT PRODUCTION PROCESS

1. Preparation of the raw materials

Selection: Select only the good quality steel without scale, crack and other impurities.

Cutting: Cut to length and diameter with ends free of burrs or other defects.

2. Refining

Purification: the removal of contaminations by a variety of means that include magnetic separation and hand picking.

Preheating: Bring to the processing temperature.

Decarbonizing: High-temperature treatment for removal of carbon, sulphur and phosphorus and for composition adjustment.

3. Processing & Forming

Preforming: The refined steel is preformed into bars.

Heat Treatment: Heat and hold at a specified temperature to impart the desired mechanical properties.

Cooling: Use air to cool naturally and stabilize structure.

Finishing: The steel round bar is further subjected to fine processing such as wire cutting and polishing to achieve higher precision and surface quality.

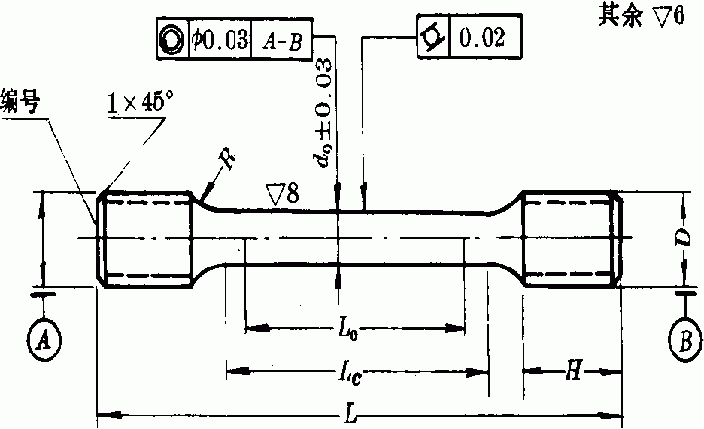

PRODUCT SIZE

-

Product Name: Steel Bar

-

Diameter: 2–500 mm

-

Length: 3000–6000 mm

-

Type: Round, Square, Hexagonal, Angle, Flat Bar

-

Surface Treatment: Cleaned, blasted, or painted as per customer requirement

-

Thickness Tolerance: ±0.1 mm

-

Material Options:

-

Carbon & Alloy Steel: 20#–50#, 16Mn–50Mn, 30Mn2–50Mn2, 20Cr, 40Cr, 20CrMnTi, 20CrMo, 15CrMo, 30CrMo, 35CrMo, 42CrMo, 42CrMo4, 60Si2Mn, 65Mn, 27SiMn, 20Mn, 40Mn2, 50Mn

-

Stainless Steel: 1Cr13, 2Cr13, 3Cr13, 4Cr13

-

Structural & Plate Steel: Q195, Q235(A–D,R), Q345(B–D,R), Q345QC, Q345QD, SPCC, SPCD, SPCE, ST37, ST12, ST15, DC01–DC06

-

-

Application: Small tools, components, iron wire, pull rods, ferrules, weld assemblies, structural metal, connecting rods, lifting hooks, bolts, nuts, spindles, axles, gears, chain wheels, car couplers

-

MOQ: 25 tons (sample orders accepted)

-

Shipment Time: 15–20 working days after deposit or TT/L/C

-

Export Packing: Waterproof paper + steel straps; standard seaworthy packing; suitable for all transport types

-

Annual Capacity: 250,000 tons/year

-

Usage Sectors: Shipbuilding, petrochemical, machinery, pharmaceuticals, power & energy, construction & decoration, nuclear power, aerospace, marine equipment, chemicals, dyes, papermaking, fertilizers, coastal infrastructure, ropes, screws, nuts, etc.

GB Standard Round Bar

Specifications: Q235,Q355,20,45,40Gr

Standard: GB/T 1499.2-2007

GB/T 1499.3-2010

Size:6-12M or customer's requirement

| Diameter Sizes (mm) | Mass per meter (kg/m | Pieces per bundle | Nonimal weight per bundle of 12 meter (metric ton) |

| 5.5 | 0.187 | 450 | 1.010 |

| 6.0 | 0.222 | 375 | 0.999 |

| 6.5 | 0.260 | 320 | 0.998 |

| 7.0 | 0.302 | 276 | 1.000 |

| 8.0 | 0.395 | 200 | 0.948 |

| 9.0 | 0.499 | 168 | 1.006 |

| 10.0 | 0.617 | 138 | 1.022 |

| 12.0 | 0.888 | 96 | 1.023 |

FEATURES

Hot rolled steel round bars, this type of steel is typically produced using a hot-rolling process, where the steel is first heated above its recrystallization temperature and then rolled through a series of rollers to achieve the desired shape. The main characteristics of hot-rolled round steel include:

-

Strength: Hot-rolled round steel bars offer high strength and toughness for diverse industrial applications.

-

Ductility: Good ductility allows easy shaping and forming into various products.

-

Surface Finish: May have a rough or scaled surface from hot rolling, which can be smoothed if needed.

-

Versatility: Widely used in construction, manufacturing, and automotive industries for structural reliability.

-

Availability: Offered in multiple sizes and grades to meet different application requirements.

APPLICATION

Building: Bending rebar for homes, schools, bridges, and roads.

Manufacturing: Machinery, equipment and industrial part production.

Automotive: Axles, shafts and structural automotive components.

Farm Machinery: Used in farm machinery for strength and formability.

General Fabrication: Gates, fences, frames and other structural applications.

DIY in the form of furniture, ornaments, small-scale buildings.

Tool Production: Works of hand tool, machine tool and industrial machinery.

PACKAGING AND SHIPPING

Packaging:

-

Stack rods neatly and securely; use straps or binding ropes to prevent shifting.

-

Wrap rods with moisture-proof materials (plastic or waterproof paper) to prevent rust and corrosion.

Transportation:

-

Choose transport based on quantity, weight, and distance (flatbed truck, container, or ship).

-

Use appropriate lifting equipment (cranes, forklifts, loaders) for safe handling.

-

Secure cargo with straps or supports to prevent movement during transit.

ng: Wrap the steel rods with moisture-proof materials (such as plastic film or waterproof paper) to protect them from moisture and other environmental factors. This helps prevent rust and corrosion.

Transportation:

Choose the appropriate mode of transport: Select the appropriate mode of transport based on the quantity and weight of the steel rods, such as flatbed trucks, containers, or ships. Consider factors such as distance, time, cost, and traffic regulations.

Use suitable lifting equipment: When loading and unloading the steel rods, use appropriate lifting equipment, such as cranes, forklifts, or loaders. Ensure the equipment has sufficient load-bearing capacity to safely handle the steel rods.

Secure the cargo: Use straps, supports, or other suitable methods to securely fasten the packaged steel rods to the transport vehicle, preventing movement, sliding, or falling during transport.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1. How can I get a quotation?

Leave us a message and we will respond promptly.

2. Will you deliver on time?

Yes, we guarantee quality products and timely delivery. Honesty is our principle.

3. Can I get samples before ordering?

Yes, samples are usually free and can be made from your sample or technical drawing.

4. What are your payment terms?

Standard terms: 30% deposit, balance against B/L. EXW, FOB, CFR, CIF available.

5. Do you accept third-party inspection?

Yes, third-party inspection is welcome.

6. How can we trust your company?

We have years of experience as a Golden Supplier, headquartered in Tianjin, and welcome verification by any method.