Advantages:

-

High section modulus-to-weight ratio for efficiency

-

Increased stiffness minimizes deflection

-

Wide design allows easy installation

-

Superior corrosion resistance, with extra thickness at critical points

The height (H) of Z-shaped steel sheet pile usually ranges from 200mm to 600mm.

The width (B) of Q235b sheet pile usually ranges from 60mm to 210mm.

The thickness (t) of Z-shaped steel sheet piles usually ranges from 6mm to 20mm.

*Send the email to [email protected] to get a quotation for your projects

| Section | Width | Height | Thickness | Cross Sectional Area | Weight | Elastic Section Modulus | Moment of Inertia | Coating Area (both sides per pile) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Flange (tf) | Web (tw) | Per Pile | Per Wall | |||||

| mm | mm | mm | mm | cm²/m | kg/m | kg/m² | cm³/m | cm4/m | m²/m | |

| CRZ12-700 | 700 | 440 | 6 | 6 | 89.9 | 49.52 | 70.6 | 1,187 | 26,124 | 2.11 |

| CRZ13-670 | 670 | 303 | 9.5 | 9.5 | 139 | 73.1 | 109.1 | 1,305 | 19,776 | 1.98 |

| CRZ13-770 | 770 | 344 | 8.5 | 8.5 | 120.4 | 72.75 | 94.5 | 1,311 | 22,747 | 2.2 |

| CRZ14-670 | 670 | 304 | 10.5 | 10.5 | 154.9 | 81.49 | 121.6 | 1,391 | 21,148 | 2 |

| CRZ14-650 | 650 | 320 | 8 | 8 | 125.7 | 64.11 | 98.6 | 1,402 | 22,431 | 2.06 |

| CRZ14-770 | 770 | 345 | 10 | 10 | 138.5 | 83.74 | 108.8 | 1,417 | 24,443 | 2.15 |

| CRZ15-750 | 750 | 470 | 7.75 | 7.75 | 112.5 | 66.25 | 88.34 | 1,523 | 35,753 | 2.19 |

| CRZ16-700 | 700 | 470 | 7 | 7 | 110.4 | 60.68 | 86.7 | 1,604 | 37,684 | 2.22 |

| CRZ17-700 | 700 | 420 | 8.5 | 8.5 | 132.1 | 72.57 | 103.7 | 1,729 | 36,439 | 2.19 |

| CRZ18-630 | 630 | 380 | 9.5 | 9.5 | 152.1 | 75.24 | 119.4 | 1,797 | 34,135 | 2.04 |

| CRZ18-700 | 700 | 420 | 9 | 9 | 139.3 | 76.55 | 109.4 | 1,822 | 38,480 | 2.19 |

| CRZ18-630N | 630 | 450 | 8 | 8 | 132.7 | 65.63 | 104.2 | 1,839 | 41,388 | 2.11 |

| CRZ18-800 | 800 | 500 | 8.5 | 8.5 | 127.2 | 79.9 | 99.8 | 1,858 | 46,474 | 2.39 |

| CRZ19-700 | 700 | 421 | 9.5 | 9.5 | 146.3 | 80.37 | 114.8 | 1,870 | 39,419 | 2.18 |

| CRZ20-700 | 700 | 421 | 10 | 10 | 153.6 | 84.41 | 120.6 | 1,946 | 40,954 | 2.17 |

| CRZ20-800 | 800 | 490 | 9.5 | 9.5 | 141.2 | 88.7 | 110.8 | 2,000 | 49,026 | 2.38 |

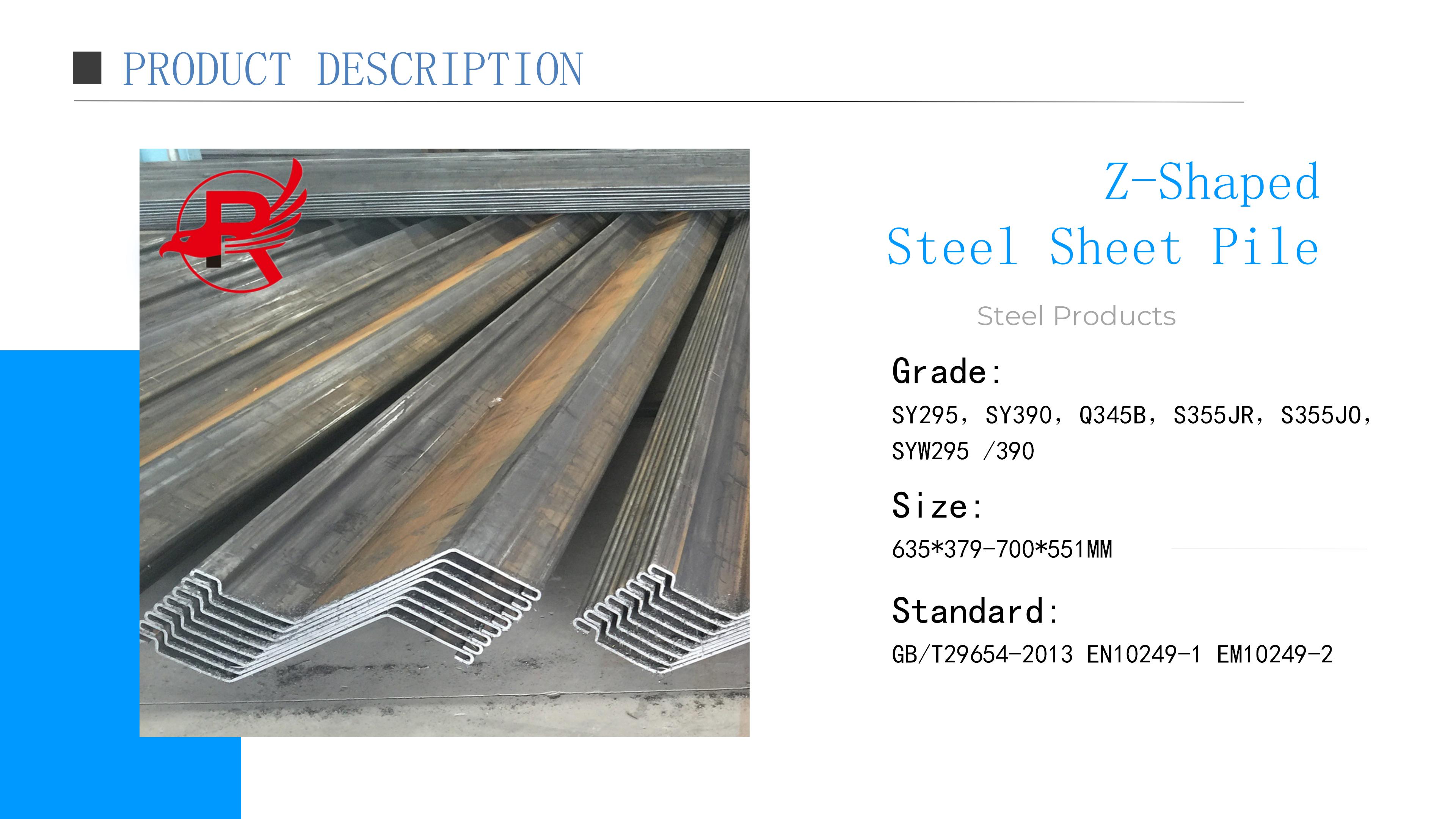

Section Modulus Range

1100-5000cm3/m

Width Range (single)

580-800mm

Thickness Range

5-16mm

Production Standards

BS EN 10249 Part 1 & 2

Steel Grades

S235JR, S275JR, S355JR, S355JO

ASTM A572 Gr42, Gr50, Gr60

Q235B, Q345B, Q345C, Q390B, Q420B

Others available on request

Length

35.0m maximum but any project specific length can be produced

Delivery Options

Single or Pairs

Pairs either loose, welded or crimped

Lifting Hole

Grip Plate

By container (11.8m or less) or Break Bulk

Corrosion Protection Coatings

|

Product Name

|

|||

|

MOQ

|

25 Ton

|

||

|

Standard

|

AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc.

|

||

|

Length

|

1-12m or as Your Requirement

|

||

|

Width

|

20-2500 mm or as Your Requirement

|

||

|

Thickness

|

0.5 - 30 mm or as Your Requirement

|

||

|

Technique

|

Hot rolled or cold rolled

|

||

|

Surface Treatment

|

Clean, blasting and painting according to customer requirement

|

||

|

Thickness tolerance

|

±0.1mm

|

||

|

Material

|

Q195; Q235(A,B,C,D R); Q345(B,C,D R); Q345QC Q345QD SPCC SPCD SPCD SPCE ST37 ST12 ST15 DC01 DC02 DC03 DC04 DC05 DC06 20#- 35# 45#

50#, 16Mn-50Mn 30Mn2-50Mn2 20Cr, 20Cr, 40Cr 20CrMnTi 20CrMo;15CrMo;30CrMo 35CrMo 42CrMo; 42CrMo4 60Si2mn 65mn 27SiMn ;20Mn; 40Mn2; 50Mn; 1cr13 2cr13 3cr13 -4Cr13; |

||

|

Application

|

It is widely used in small tools, small components, iron wire, siderosphere, pull rod, ferrule, weld assembly, structural metal,

connecting rod, lifting hook, bolt, nut, spindle, mandrel, axle, chain wheel, gear, car coupler. |

||

|

Export packing

|

Waterproof paper, and steel strip packed.Standard Export Seaworthy Package.Suit for all kinds of transport,or as required

|

||

|

Application

|

Shipbuilding,marine steel plate

|

||

|

Certificates

|

ISO,CE

|

||

|

Delivery Time

|

Usually within 10-15 days after receipt of advance payment

|

||

The outer fibers are interlocked, which optimizes the cross-section profile and gives high strength with light material.

High inertia reduces deflection and results in better performance

.

High steel grades enable a very efficient cross section with a high bending moment capacity.

Good driving stiffness is also ensured by the constant cross sectional thickness.

The system is wider than the standard sheet piles and this extra width cuts down on the time for handling and installing with traditional manner of driving.

The widened spacing reduces the number of interlocks per lineal meter of wall, enhancing the tightness of the wall.

Z steel sheet piles have a wide range of applications in civil engineering and construction. Some common applications include:

Sheet piles All profiles supplied are hot-rolled steel sheet piles are suitable for permanent and temporary work. For permanent use they are suitable for wharfs, docks, retaining walls, breakwaters, embankments and gates. When used for temporary work, they can be used for cofferdams, pipeline trenches, excavation, and flood control, so long as they prevent soil erosion, flooding and the displacement of sand.

![0$NU_O5TD8Y4}`E3UXEVP]2](http://www.chinaroyalsteel.com/uploads/0NU_O5TD8Y4E3UXEVP2.jpg)

Packaging:

Stack the sheet piles:Stack your Z sheet piles neatly and securely - they should be the same size and they should not move at all. Place a band/strap or two around the sheet piles at your preferred distance to keep them bundled and prevent air between them as you transport them.

Protective Packaging: Sheet pile should be covered with a protective packaging (e.g., plastic or kraft paper) to protect against water intrusion, moisture and/or other environmental exposure. This prevents rust and corrosion.

Transportation:

Choose “Right Transport”: Select right type of transport i.e flatbed truck, container, ship for the quantity and weight of the sheet piles. Consider the distance, time, cost of transportation and any applicable related regulations.

Operate with proper equipment: At your site, employ proper equipment for loading and unloading the U-shaped sheet piles, e.g., crane, forklift, or loader. Check that it is rated high enough to safely support the weight of sheet pile stacks.

Secure the load: Strap, brace, or otherwise secure the round bales of sheet pile stack to the transport vehicle so that they don’t slide, shift, or topple while in transit.

The production process of cold-formed steel sheet pile usually includes the following steps:

1.Material Preparation: Select hot-rolled or cold-rolled steel plates that meet design requirements and relevant standards.

2.Cutting: Cut the steel plates to required lengths to form blanks.

3.Cold Bending: Form the blanks into Z-shaped cross-sections using rolling and bending machines.

4.Welding: Weld the Z-shaped piles to ensure strong, defect-free connections.

5.Surface Treatment: Apply rust removal, painting, or other treatments to enhance corrosion resistance.

6.Inspection: Check appearance, dimensions, and weld quality to ensure compliance with standards.

7.Packaging & Dispatch: Package and label qualified piles before shipping from the factory.

*Send the email to [email protected] to get a quotation for your projects

When a customer wants to see a product, these options are typically available:

Schedule a visit to view the product: Buyers may also contact the manufacturer or sales representative directly to schedule a time and place to get a closer look at the product.

Book a guide tour: Book an expert or a sales assistant as your guide through the production process, technology and quality control system of the product.

Display products: Make products available, at various stages of completion, to visitors on tours, so that they can see how your products are made, and the extent of your product quality.

Answer questions: Of course, the customers can for some questions during the explaining, and the guide or the sales have to be patient to answer the questions, and there also can be some related technical and quality knowledge.

Serve up samples: You could be able to bring some samples of the product to the customers, so that they can better understand the quality and the function of your product.

Take further action: Wait for the feedback from customers, if they have any, and if new demands occur, grant them and take further service to customers.

As one of the top China AZ Sheet Pile manufacturers, our steel sheet piles are of high quality and long-lasting suitable for any construction site.

Solidity and cleanliness

The sheet piles are corrosion resistant, and can be used for heavy and high load applications, which makes them a solid foundation for your projects.

Customer services

We are with you through design and installation to provide the best shoring solution for your needs. Suitable for all sizes, such as AZ, PZ, NZ sheet piles.

Q: Are you a trading company or manufacturer?

A: We are a manufacturer with our own warehouse and trading operations.

Q: What is your delivery time?

A: Usually 5–10 days for in-stock items, or 15–20 days for custom orders, depending on quantity.

Q: Do you provide samples? Is it free?

A: Yes, samples are free; customers only cover shipping costs.

Q: What is your MOQ?

A: Minimum order is 1 ton; 3–5 tons for customized products.