Custom Accurate Hole Positioning of Perforated U-shaped Steel Workpiece

Product Detail

Steel fabrication refers to the custom manufacturing of steel components based on customer-provided drawings and specifications. We utilize advanced technology and adhere to a philosophy of continuous improvement and quality excellence to ensure high-quality products. Even if customers do not have design drawings, our product designers can create designs based on their specific requirements.

The main types of processed parts :

welded parts, perforated products, coated parts, bent parts, cutting parts

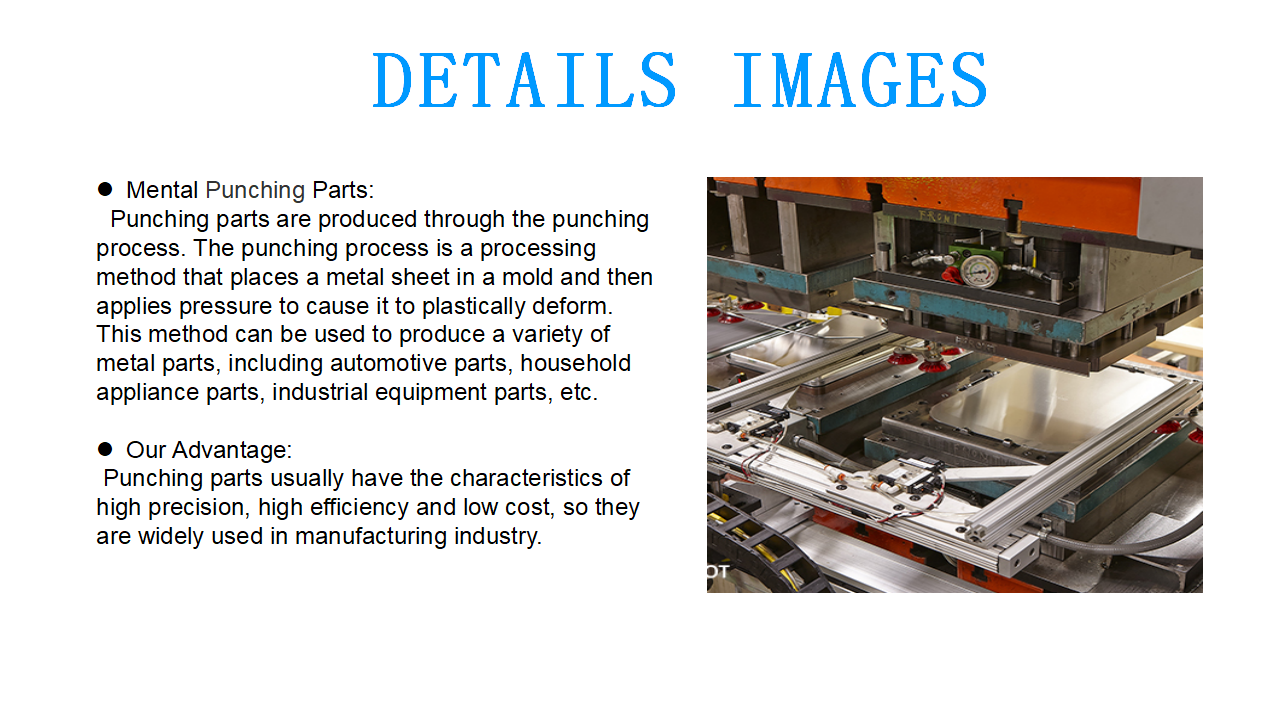

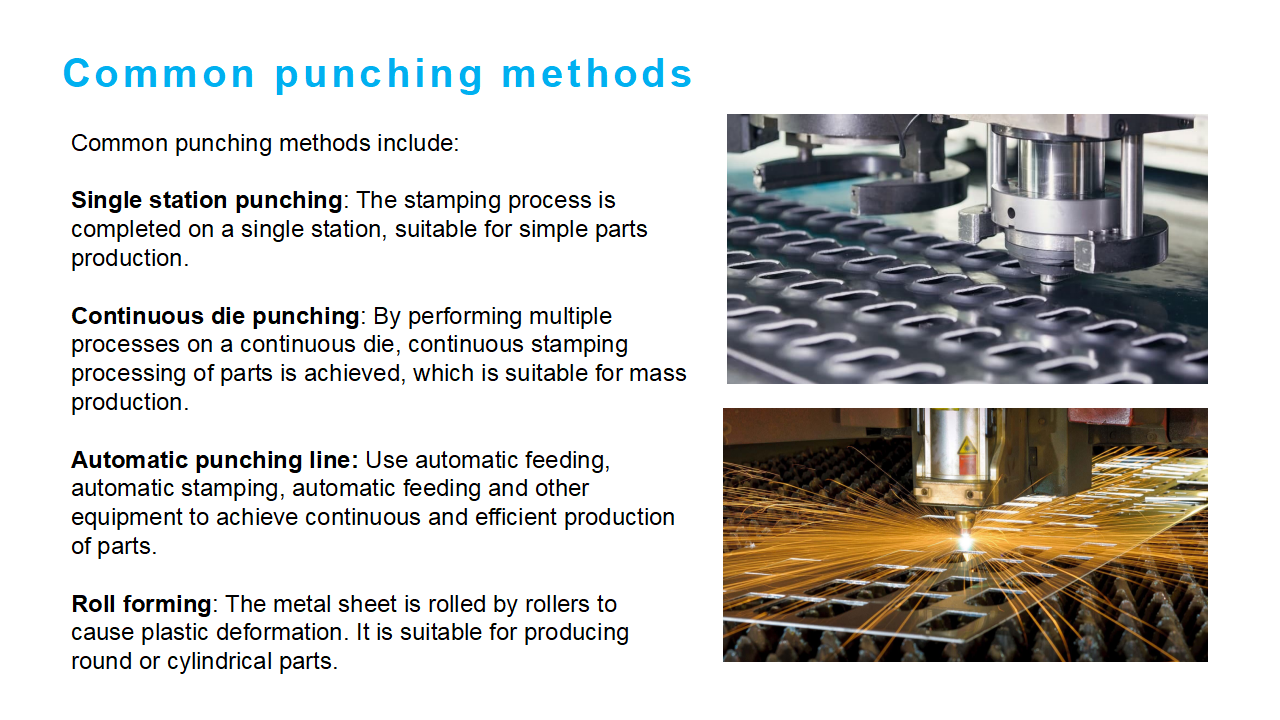

Metal punching, also known as sheet metal punching or steel punching, is a crucial process in the manufacturing industry. It involves the use of specialized equipment to create holes, shapes, and patterns in metal sheets with precision and accuracy. This process is essential for creating a wide range of products, from automotive parts to household appliances.

One of the core technologies in metal stamping is CNC (Computer Numerical Control) stamping. CNC technology automates the stamping process, ensuring high precision and efficiency. CNC stamping services offer an economical and efficient solution for the mass production of complex metal parts.

Metal stamping has numerous advantages. It can produce intricate and complex patterns on metal sheets, making it suitable for a wide range of applications. Furthermore, it is a fast and efficient production process that yields high-quality components, making it an ideal choice for manufacturers looking to streamline their production processes.

In addition to its versatility and efficiency, metal punching also offers the advantage of cost-effectiveness. By using CNC punching services, manufacturers can reduce material waste and minimize production time, resulting in significant cost savings. This makes metal punching an attractive option for businesses looking to optimize their manufacturing processes.

Furthermore, metal stamping is a sustainable manufacturing process because it efficiently utilizes materials and resources. By minimizing waste and improving production efficiency, metal stamping contributes to more sustainable and environmentally friendly manufacturing practices.

|

Item

|

Oem Custom Punching Processing Pressing Hardware Products Service Steel Sheet Metal Fabrication

|

|

Material

|

Aluminum, Stainless Steel, Copper, Bronze, Iron

|

|

Size or shape

|

According to Customer Drawings or Requests

|

|

Service

|

Sheet Metal Fabrication / CNC Machining / Metal cabinets&enclosure&box / Laser Cutting Service / Steel Bracket / Stamping Parts, etc.

|

|

Surface treatment

|

Powder spraying, Fuel injection, Sandblasting, Copper plating, Heat treatment, Oxidation, Polishing, Assivation, Galvanizing, Tin

plating, Nickel plating, Laser carving, Electroplating, Silk screen printing |

|

Drawing accepted

|

CAD, PDF, SOLIDWORKS, STP, STEP, IGS, etc.

|

|

Service mode

|

OEM or ODM

|

|

Certification

|

ISO 9001

|

|

Feature

|

Focus on high end market products

|

|

Processing procedure

|

CNC Turning, Milling, CNC Machining, Lathe, etc.

|

|

Package

|

Inner pearl button, Wooden case, or Customized.

|

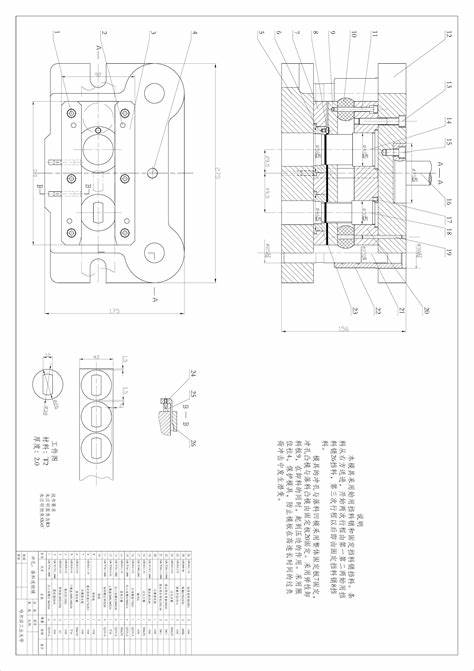

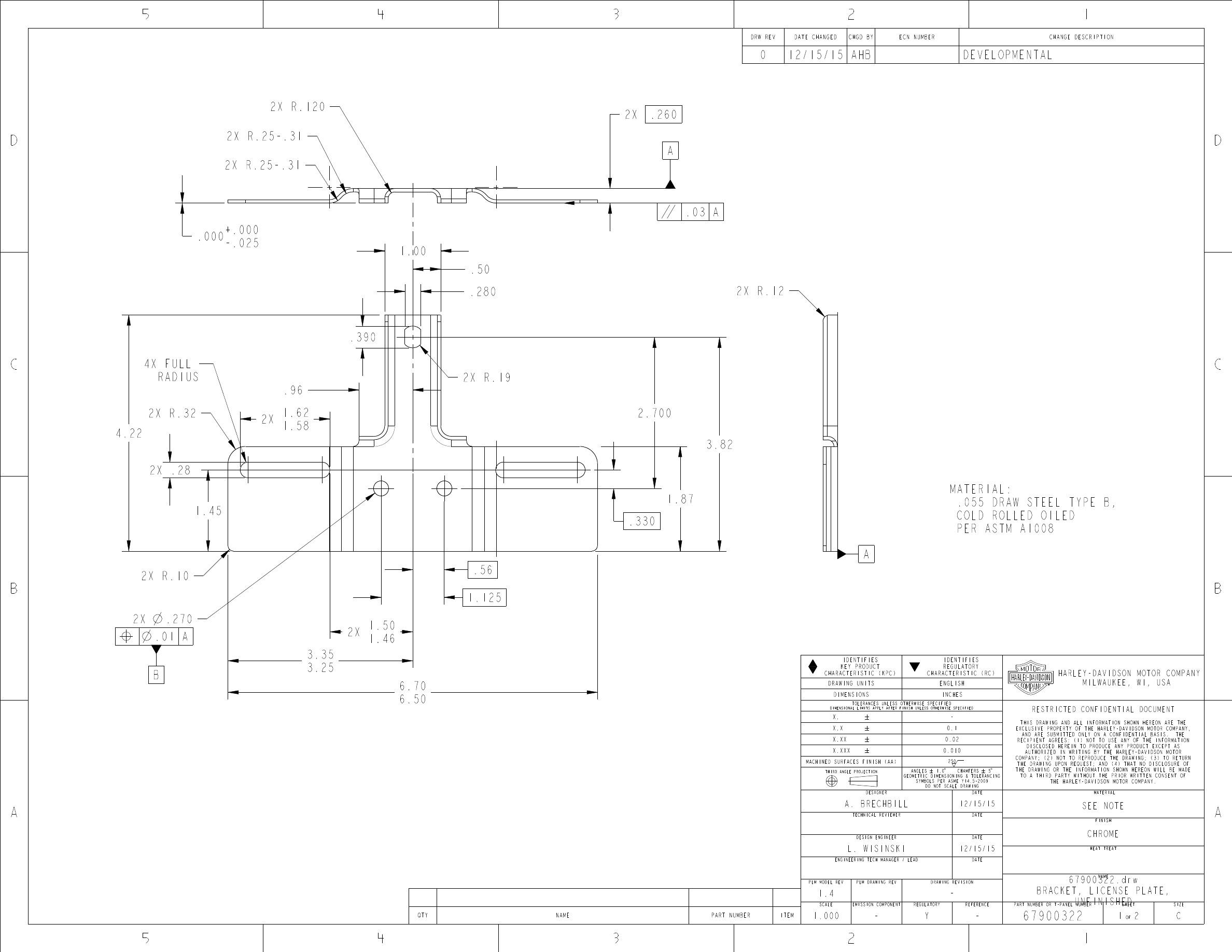

Exemplify

This is the order we received for processing parts.

We will produce accurately according to the drawings.

|

Customized Machined Parts |

|

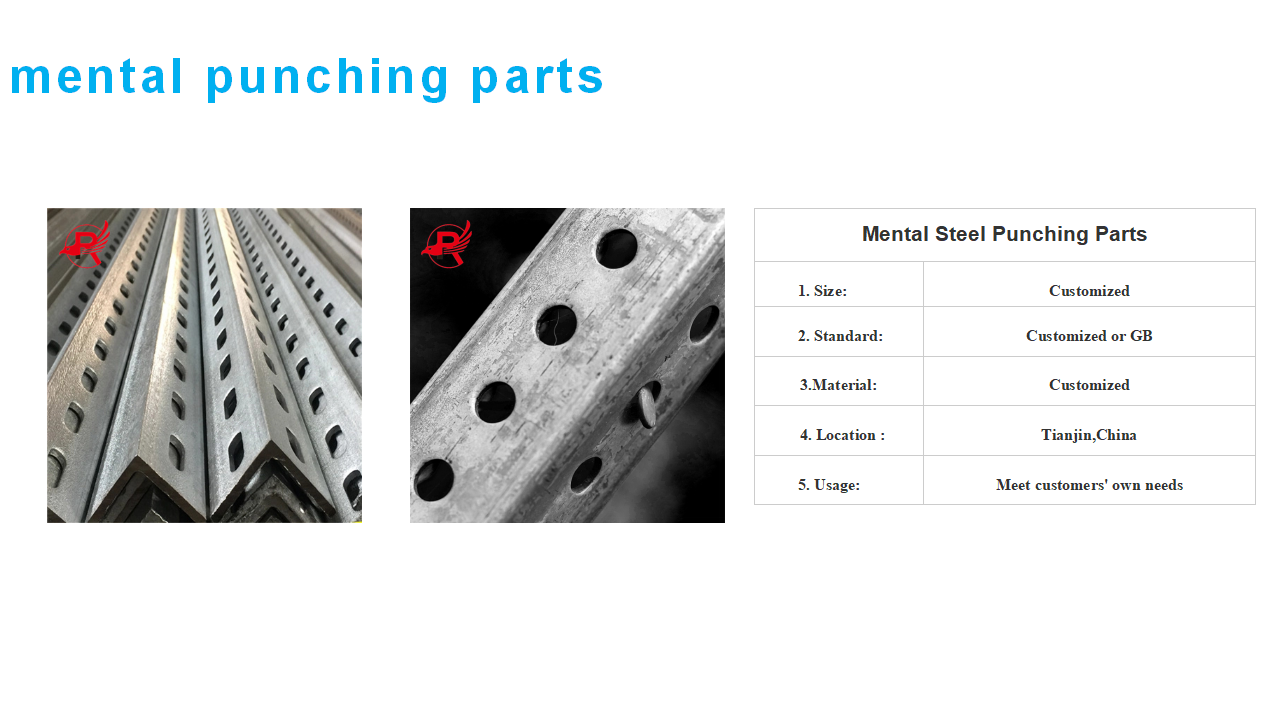

| 1. Size | Customized |

| 2. Standard: | Customized or GB |

| 3.Material | Customized |

| 4. Location of our factory | Tianjin,China |

| 5. Usage: | Meet customers' own needs |

| 6. Coating: | Customized |

| 7. Technique: | Customized |

| 8. Type: | Customized |

| 9. Section Shape: | Customized |

| 10. Inspection: | Client inspection or inspection by 3rd party. |

| 11. Delivery: | Container, Bulk Vessel. |

| 12. About Our Quality: | 1) No damage, no bent2) Accurate dimensions3) All goods can be checked by third party inspection before shipment |

As long as you have personalized steel product processing needs, we can accurately produce them according to the drawings. If there are no drawings, our designers will also make personalized designs for you based on your product description needs.

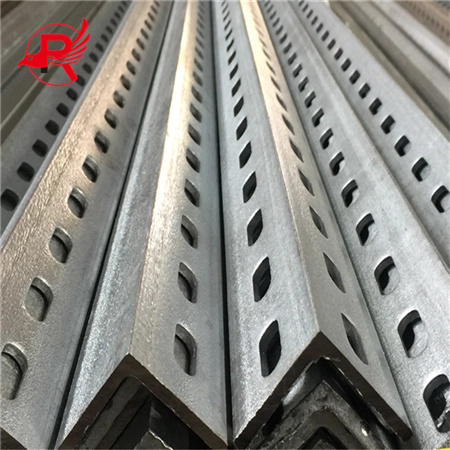

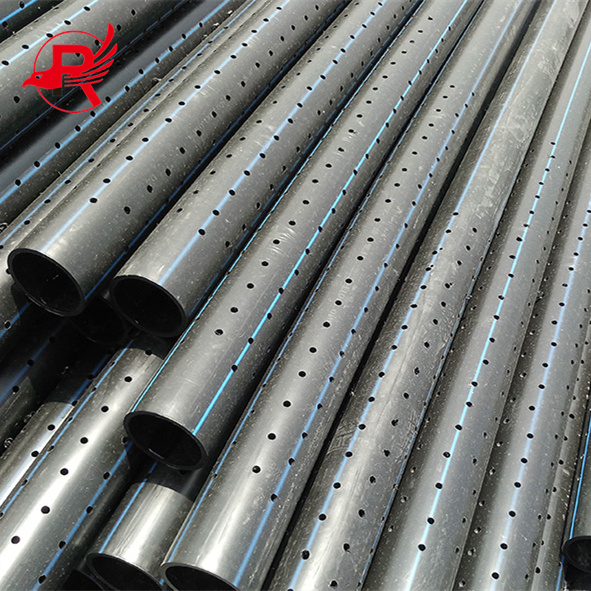

Finished product display

Packaging & Shipping

Package:

We will package the products according to customer needs, using wooden boxes or containers, and the larger profiles will be directly packed naked, and the products will be packaged according to customer needs.

Shipping:

Choose the appropriate mode of transport: Based on the quantity and weight of the customized products, select an appropriate mode of transport, such as flatbed trucks, containers, or ships. Consider factors such as the distance, time, cost, and relevant transportation regulations.

Use suitable lifting equipment: When loading and unloading the steel sheet piles, use appropriate lifting equipment, such as cranes, forklifts, or loaders. Ensure that the equipment has sufficient load-bearing capacity to guarantee safe handling of the steel sheet piles.

Secure the cargo: Use tie-down straps, supports, or other suitable methods to securely fasten the packaged customized products to the transport vehicle to prevent damage or loss during transit.

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.