Click to get a FREE 3D Design and Quote within 24 hours!

Custom ASTM Standard Prefabricated & Heavy Steel Structures for Infrastructure & Industrial Projects

APPLICATION

Warehouses and Logistics Centers: Prefabricated steel structures provide fast and cost-effective construction for warehouses and logistics facilities. Modular components allow quick assembly while ensuring structural strength and durability.

Industrial factories and plat production: Heavy steel structures like H-beams, I-beams, steel plates are used to support high-load-bearing industrial operations. These platforms are suitable for machinery platforms, production lines and factory halls.

Bridges and Infrastructure Projects: Steel structures are widely used in bridges, highways, and energy infrastructure due to their strength, precision, and adaptability to complex engineering requirements.

Commercial and public buildings: Prefabricated steel frames provide a contemporary and adaptable solution for commercial buildings including shopping centres, office blocks, sports halls.

PRODUCT DETAIL

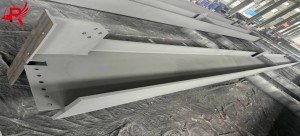

Core steel structure products for factory construction

1. Main load-bearing structure (adaptable to tropical seismic requirements)

| Product Type | Spec Range | Core Function | Central America Adaptation |

|---|---|---|---|

| Portal Frame Beam | W12×30 ~ W16×45 (ASTM A572 Gr.50) | Main roof & wall load beam | Seismic bolted joints; optimized for lighter weight & easy transport |

| Steel Column | H300×300 ~ H500×500 (ASTM A36) | Floor & frame support | Seismic connectors; hot-dip galvanized (Zn ≥85 μm) for humid climates |

| Crane Beam | W24×76 ~ W30×99 (ASTM A572 Gr.60) | Crane load-bearing beam | High-capacity (5–20t); end beams with shear plates |

2. Enclosure system products (weatherproof + anti-corrosion)

Roof Purlins: C12×20 up to C16×31, hot dipped galvanized, 1.5-2m in spacing. They are good for color coated steel panels and 12 level typhon resisitance.

Wall Purlins: Z10×20 to Z14×26 with rust preventive paint (dried salt spray over 1000 hours) It also has ventilation holes to let the tropical factory moisture-cond come out.

Support System: Galvanized round steel Φ12~Φ16 and angle (L50×5 steel angle) for bracing increase the sideway stability against the wind force of hurricane).

3. Supporting auxiliary products (localized construction adaptation)

Precast Part: Hot-dip galvanized steel plate (thickness: 10–20 mm) for concrete footing, available for purchase in Costa Rica and for import in other countries of Central America.

Bolts: High strength bolts (grade 8.8, hot dip galvanized) are utilized instead of welding in the field, reducing the assembly time.

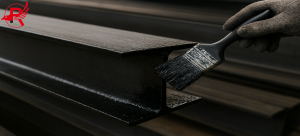

Fire & Corrosion Protection: Water based intumescent coating (≥1.5 h fire protection), UV resistant acrylic anti-corrosive coating (≥10 years service life), complying with local environmental protocols.

STEEL STRUCTURE PROCESSING

| Processing Method | Machines Used | Description |

|---|---|---|

| Cutting | CNC plasma/flame cutters, shears | Plasma/flame for steel plates, shearing for thin plates with precision |

| Forming | Cold bending, press brake, rolling | Cold bending for purlins, gutters, trims; rolling for round supports |

| Welding | Submerged arc, manual arc, CO₂ | Submerged arc for H-columns/beams; manual for gusset plates; CO₂ for thin sections |

| Holemaking | CNC drilling, punching machines | CNC bolt holes; small batch punching with exact positioning |

| Surface Treatment | Shot/sand blasting, grinder, galvanizing line | Rust removal, weld grinding, hot-dip galvanizing for bolts & supports |

| Assembly | Platforms, measuring tools | Pre-assembly of columns, beams & bracings; disassembled after dimensional check |

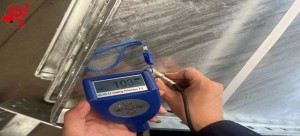

STEEL STRUCTURE TESTING

| Test Type | Standard(s) | Purpose / Notes |

|---|---|---|

| Salt Spray Test | ASTM B117, ISO 11997-1 | Corrosion resistance for Central American coastal conditions |

| Adhesion Test | ISO 2409 / ASTM D3359 (crosshatch), ISO 4624 / ASTM D4541 (pull-off) | Control coating adhesion and peel strength |

| Humidity & Heat Resistance | ASTM D2247 (40°C / 95% RH) | Prevent blistering and cracking in rainy conditions |

| UV Aging Test | ASTM G154 | Protect against UV-induced fading and chalking |

| Film Thickness Test | ASTM D7091 (dry), ASTM D1212 (wet) | Ensure coating thickness meets corrosion protection requirements |

| Impact Strength Test | ASTM D2794 (drop hammer) | Protect coating during transport and storage |

SURFACE TREATMENT

PACKAGING AND SHIPPING

Packaging:

The steel is well packed with surface protection and stiffness maintaining agent for handling.

Small accessories are packaged in wooden boxes, with waterproof wrapping, plastic or rust-proof paper.

Boxes and bundles are labelled clearly so that they may be safely unloaded and efficiently installed.

Transportation:

Container or bulk vessel shipping depending on load size and destination.

Bulky or heavy goods are restrained from moving using steel strapping and wood blocks.

All delivery conform to international transport regulations for delivery security and reliability.

WHY CHOOSE OUR STEEL STRUCTURES?

Clear Span Design: Maximize your internal workspace with unobstructed layouts (up to 30m+ without interior columns).

Low Maintenance: Our hot-dip galvanizing process ensures maximum protection against rust and corrosion in harsh environments.

Turnkey Solution: From initial 3D CAD drawings to shipping and installation guidance, we provide a seamless one-stop service.

Eco-Friendly: Steel is 100% recyclable, making it the preferred choice for modern green construction.

Ready to start your project?

FAQ

Q1: What are the quality standards of your products?

A1: We meet the ASTM, EN, AS/NZS, JIS standards. All materials with the Mill Test Certificate (MTC).

Q2: Can you make products for the high-corrosion environment?

A2: Yes. We provide the Hot-Dipped Galvanizing (HDG) and coatings that meet the ASTM B117 Salt Spray Test for marine use.

Q3: Do you have samples

A3: Yes, we offer free samples for standard profiles, courier cost will be returned upon order in bulk.

Q4: What about packing of the product?

A4: We pack in a seaworthy manner(strapping, anti-rust oil, steel pallets) to ensure goods arrived at you on good condition.

Q5: What is your payment term?

A5: Our payment method is T/T (30% deposit) or 100% L/C at sight.

Q6: Do you accept third-party inspection?

A6: Yes, we work with SGS, BV, Or TUV for your preshipment inspection.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506