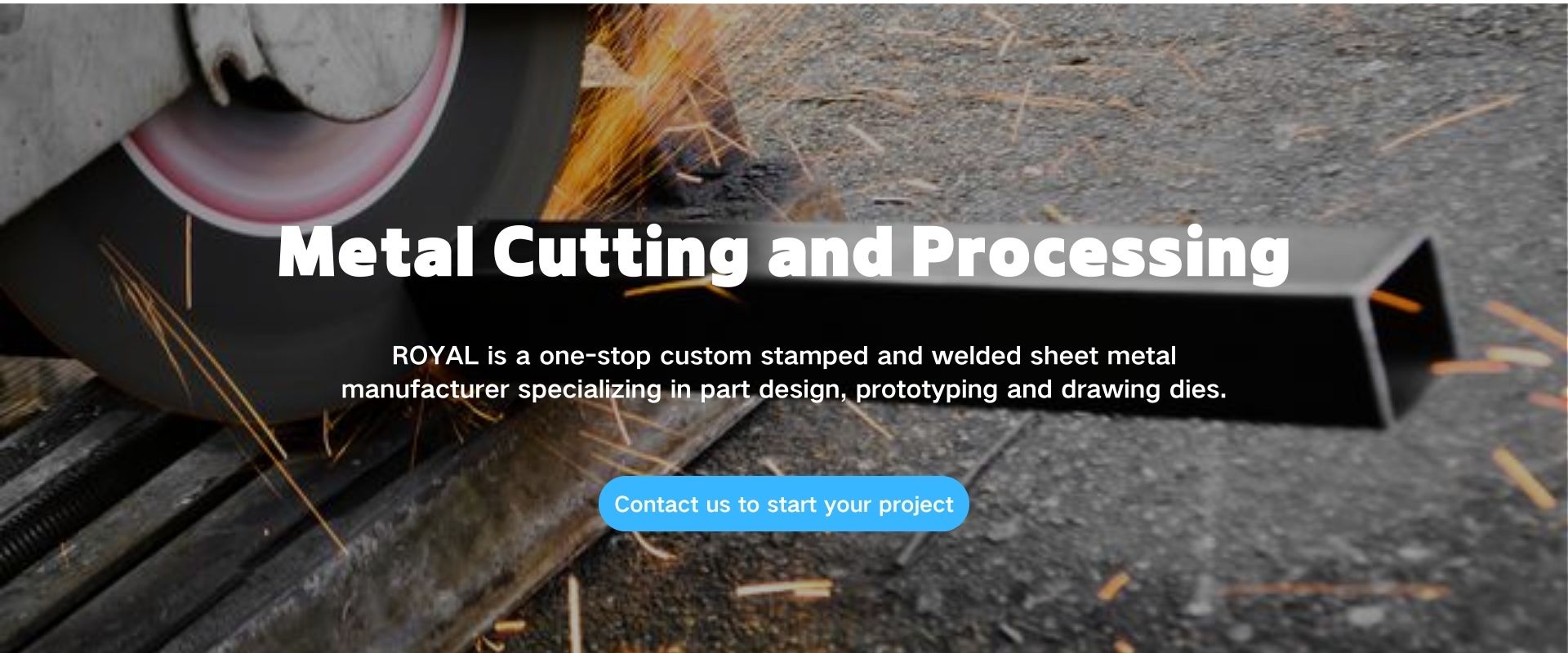

Custom Meta Steel Profile Cutting Service Sheet Metal Fabrication

Product Detail

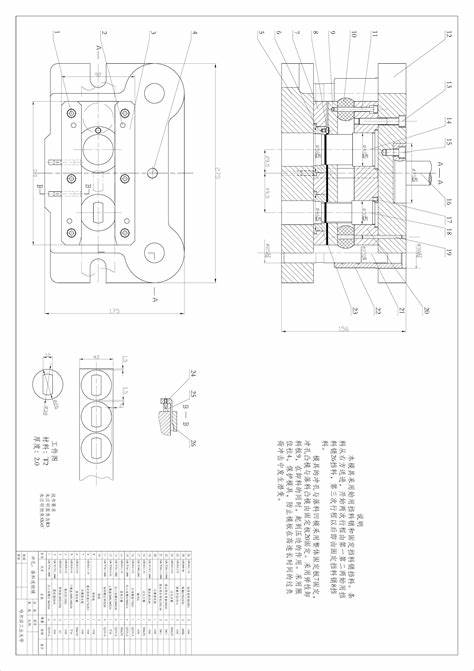

Steel parts are made from raw steel. Based on customer drawings, we customize and manufacture molds based on the required specifications, dimensions, material, and surface treatment. We deliver precision, high-quality, and high-tech production tailored to your needs. Even if you don't have a design drawing, our designers will design it to your specifications.

The main types of processed parts :

welded parts, perforated products, coated parts, bent parts, cutting parts

Plasma cutting is widely used in metalworking, machinery manufacturing, aerospace, and other fields. In metalworking, plasma cutting can be used to cut a variety of metal parts, such as steel plates and aluminum alloys, ensuring precision and quality. In aerospace, plasma cutting is used to cut aircraft parts, such as engine components and fuselage structures, ensuring precision and lightweighting.

In short, as an efficient and high-precision cutting technology, plasma cutting has broad application prospects and market demand, and will play a vital role in the future manufacturing industry.

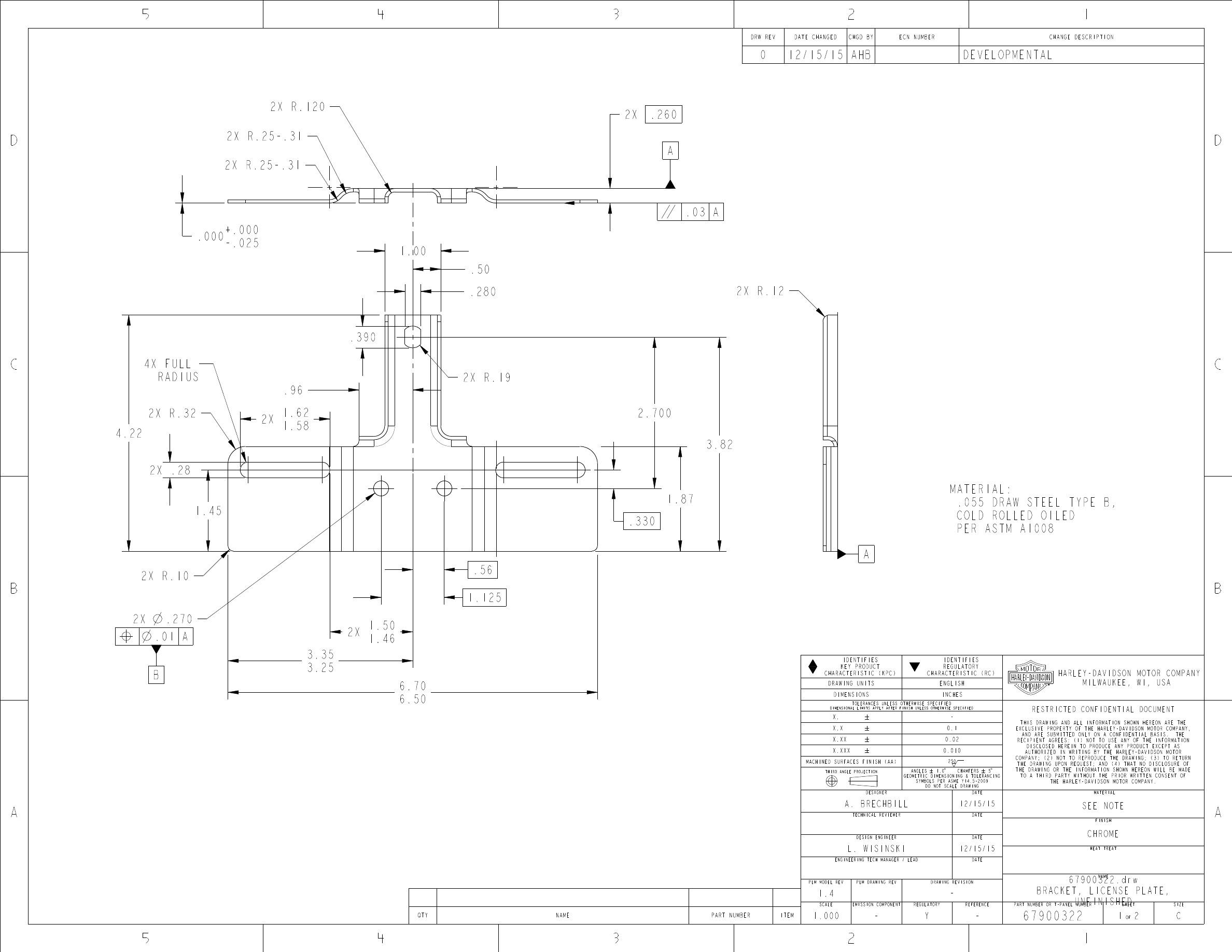

Advantages of Laser Cutting Sheet Metal in Manufacturing

In manufacturing, precision and efficiency are key factors in producing high-quality products. Laser cutting of sheet metal was born to address these needs, bringing widespread benefits to a wide range of industries. From automotive to aerospace, from electronics to construction, laser cutting technology has revolutionized the way sheet metal is processed and utilized.

Laser cutting of sheet metal requires the use of a high-powered laser to cut material with extreme precision. This process enables the cutting of complex designs and shapes while minimizing material waste. Laser cutting can cut a variety of metals, including steel, aluminum, and copper, making it a versatile solution for numerous manufacturing needs.

One of the primary advantages of laser cutting sheet metal is its high precision. Laser cutting's accuracy enables tight tolerances and intricate details, resulting in seamless assembly of parts and assemblies. This precision is crucial in industries where even the smallest deviation can lead to significant issues with the final product.

Furthermore, laser cutting offers a faster and more efficient method for processing sheet metal than traditional methods. Thanks to CNC technology, designs can be programmed and executed with minimal setup time, reducing turnaround time and increasing productivity. This is particularly beneficial for industries requiring high-volume production.

In addition to its precision and efficiency, laser cutting sheet metal also offers long-term cost savings. Reduced material waste and the ability to produce complex designs without the need for additional tooling lower production costs for manufacturers, resulting in overall savings.

Furthermore, the flexibility of laser cutting technology enables customization and prototyping without the limitations of traditional tooling methods. This means manufacturers can quickly adapt to design changes and produce small batches of customized parts without incurring high setup costs.

In summary, the advantages of laser cutting sheet metal in the manufacturing industry are undeniable. From precision and efficiency to cost savings and flexibility, laser cutting technology has become an indispensable tool for industries seeking high-quality, custom metal parts. As technology continues to advance, the potential of laser cutting in the manufacturing industry will continue to grow, providing more innovative solutions for the industry.

|

Custom Precision Sheet Metal Fabrication Parts

|

||||

|

Quotation

|

According to your drawing(size, material, thickness, processing content, and required technology, etc)

|

|||

|

Material

|

Carbon steel, stainless steel,SPCc, SGCc, pipe, galvanized

|

|||

|

Processing

|

Laser cutting, bending, riveting, drilling, welding, sheet metal forming, assembly, etc.

|

|||

|

Surface Treatment

|

Brushing, Polishing, Anodizing, Powder Coating, Plating,

|

|||

|

Tolerance

|

'+/-0.2mm, 100% QC quality inspection before delivery, can provide quality inspection form

|

|||

|

Logo

|

Silk print, Laser marking

|

|||

|

Size/Color

|

Accepts custom sizes/colors

|

|||

|

Drawing Format

|

.DWG/.DXF/.STEP/.IGS/.3DS/.STL/.SKP/.AI/.PDF/.JPG/.Draft

|

|||

|

Sample Ead Time

|

Negotiate delivery time according to your needs

|

|||

|

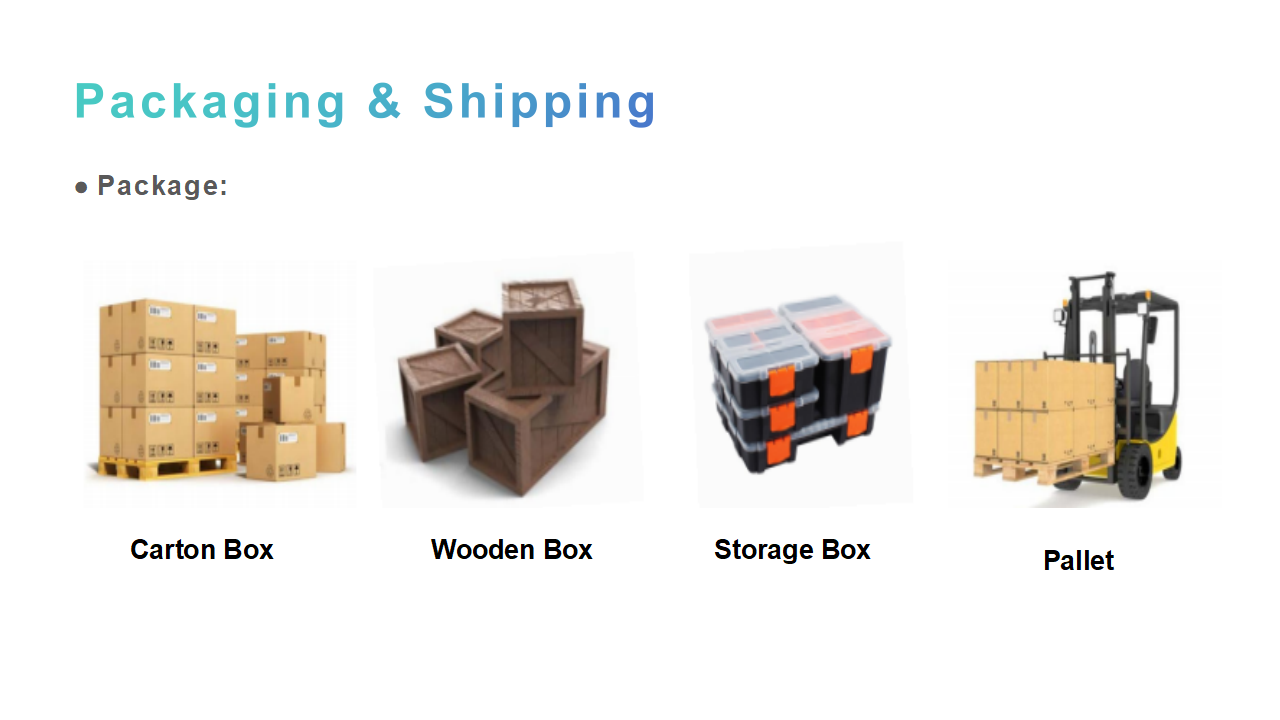

Packing

|

By carton/crate or as per your requirement

|

|||

|

Certificate

|

ISO9001:SGS/TUV/ROHS

|

|||

Exemplify

|

Customized Machined Parts |

|

| 1. Size | Customized |

| 2. Standard: | Customized or GB |

| 3.Material | Customized |

| 4. Location of our factory | Tianjin,China |

| 5. Usage: | Meet customers' own needs |

| 6. Coating: | Customized |

| 7. Technique: | Customized |

| 8. Type: | Customized |

| 9. Section Shape: | Customized |

| 10. Inspection: | Client inspection or inspection by 3rd party. |

| 11. Delivery: | Container, Bulk Vessel. |

| 12. About Our Quality: | 1) No damage, no bent2) Accurate dimensions3) All goods can be checked by third party inspection before shipment |

Finished Product Display

Packaging & Shipping

The packaging and transportation of plasma-cut parts are crucial for ensuring product quality and safe delivery. First, due to the high precision and quality of plasma-cut parts, appropriate packaging materials and methods are essential to prevent damage during transportation. Small plasma-cut parts can be packaged in foam boxes or cartons. Large plasma-cut parts are typically packaged in wooden crates to protect them from damage during transportation.

During the packaging process, the parts should be properly secured and padded according to their characteristics to prevent damage from impact and vibration during transportation. For plasma-cut parts with unusual shapes, customized packaging solutions are required to ensure their stability during transportation.

During transportation, it is important to select a reliable logistics partner to ensure the safe and timely delivery of plasma-cut parts. For international shipments, it is also important to understand the relevant import regulations and transportation standards of the destination country to ensure smooth customs clearance and delivery.

Furthermore, for plasma-cut parts made of special materials or with complex shapes, special requirements such as moisture and corrosion protection must be taken into consideration during packaging and transportation to ensure product quality is not compromised.

In short, the packaging and transportation of plasma-cut parts are important links to ensure product quality and customer satisfaction. Reasonable planning and operation are required in terms of packaging material selection, fixed filling, and transportation method selection to ensure that the products are delivered to customers safely and intact.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

CUSTOMERS VISIT

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.