Customizable Galvanized Steel Hot dipped Galvanized Steel 150 5mm C Purlin Channel

Galvanized C Channel steel is a new type of steel made from Q235B steel plates through cold bending and roll forming. It features uniform wall thickness and excellent cross-sectional properties. It is widely used in C purlins and wall beams in steel structures, as well as beam-column structures in machinery manufacturing. This profile is hot dip galvanized C Channel, with a surface zinc content of 120-275g/㎡. In urban environments, it has a service life of over 20 years, and the coating's toughness resists damage during transportation and construction.

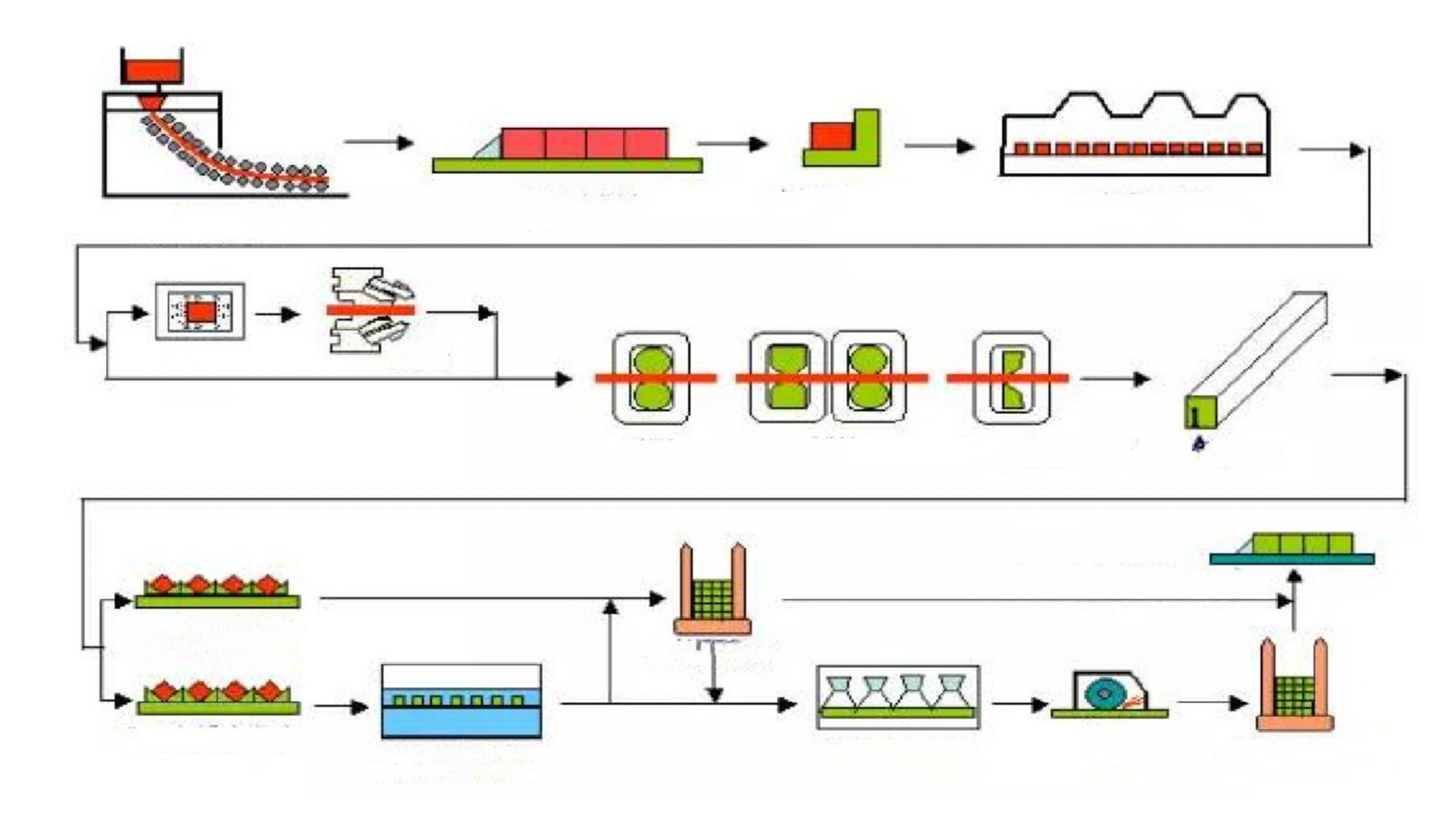

PRODUCT PRODUCTION PROCESS

The production of C-shaped channel steel uses continuous casting steel billets as raw materials. The core process is divided into five steps: first, inspect the steel billets to remove defects; then heat them to 1100-1250℃ in a continuous heating furnace to ensure plasticity and prevent overburning; then go through multiple passes of rough rolling, intermediate rolling, and finishing rolling to gradually form a C-shaped cross-section, during which time scale removal and scarring are prevented; after rolling, slowly cool them to room temperature on a cooling bed to avoid stress cracking; finally, cut to length, straighten and correct the size, clean the surface and inspect the appearance and performance, spray-mark the qualified ones and put them into storage, and add anti-corrosion or deep processing steps as needed.

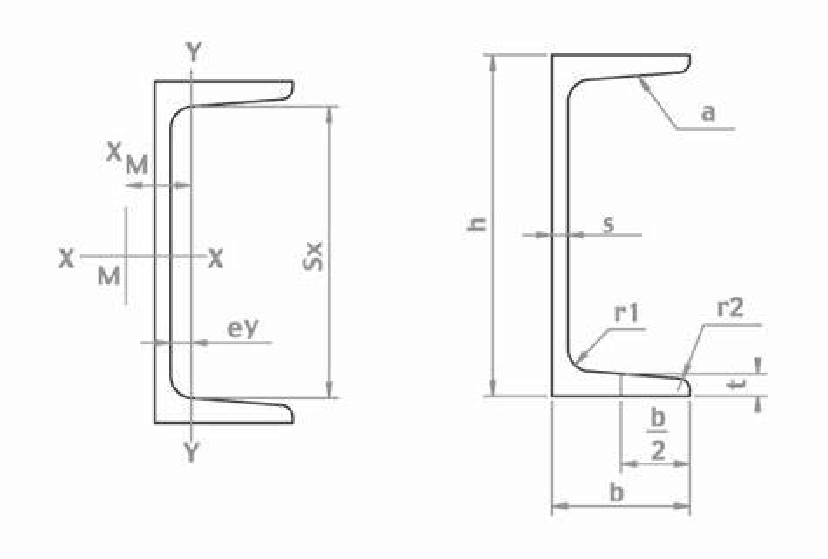

PRODUCT SIZE

| UPN EUROPEAN STANDARD CHANNEL BAR DIMENSION:DIN 1026-1:2000 STEEL GRADE:EN10025 S235JR |

|||||

| SIZE | H(mm) | B(mm) | T1(mm) | T2(mm) | KG/M |

| UPN 140 | 140 | 60 | 7.0 | 10.0 | 16.00 |

| UPD 160 | 160 | 65 | 7.5 | 10.5 | 18.80 |

| UPN 180 | 180 | 70 | 8.0 | 11.0 | 22.0 |

| UPN 200 | 200 | 75 | 8.5 | 11.5 | 25.3 |

Grade:

S235JR,S275JR,S355J2,etc.

Size:UPN 80,UPN 100,UPN 120,UPN 140.UPN160,

UPN 180,UPN 200,UPN 220,UPN240,UPN 260.

UPN 280.UPN 300.UPN320,

UPN 350.UPN 380.UPN 400

Standard:EN 10025-2/EN 10025-3

FEATURES

Cross-sectional Advantages: The "C"-shaped open cross section features a smooth transition between the web and flange, effectively distributing longitudinal loads. In applications such as buildings and scaffolding, it offers excellent bending and torsional resistance, and its open design facilitates connection and assembly with other components (such as plates and bolts).

Economical: Compared to solid steel of equal weight, it offers high cross-sectional utilization, resulting in less consumables for the same load-bearing requirements. The mature production process (primarily hot rolling) allows for low mass production costs, resulting in a better price-performance ratio than some custom steel sections.

Flexible Size: Height, leg width, waist thickness, and length can be customized according to standards (such as GB/T 706) or on-demand, adapting to projects with varying spans and loads, from small scaffolding to large building structures.

Easy Processing: The smooth surface facilitates secondary processing such as cutting, drilling, welding, and bending. The open structure facilitates the routing of pipes and cables, improving installation efficiency in applications such as steel structure construction and equipment frameworks.

Strong adaptability: It can improve weather resistance through anti-corrosion treatment such as hot-dip galvanizing and spraying, and is suitable for harsh environments such as outdoor and humid environments; it can also be used with I-beams, angle steels, etc. to form a stable composite load-bearing structure.

APPLICATION

C-shaped channel steel's main applications

1. Construction Engineering: Customers can use customized c channel in the building.Used in steel structure buildings as purlins (supporting roof/wall panels) and keels, or as secondary load-bearing components in lightweight steel structures, such as factories, warehouses, and prefabricated buildings, leveraging its bending resistance to reduce the overall structural weight.

2. Equipment and Support Manufacturing: Used in the manufacture of bases and frames for mechanical equipment (such as machine tools and conveying equipment), or support brackets for air conditioners, pipes, and cables. Its open design facilitates fixed installation and reduces material costs.

3. Transportation and Logistics: Used in container frames, truck bed frames, and warehouse racking columns and beams. Its high strength meets the impact resistance requirements of cargo loading and transportation.

4. New Energy: Used as supporting purlins for photovoltaic panels in photovoltaic power plants, or as auxiliary structural components for wind turbines. Anti-corrosion treatment (such as hot-dip galvanizing) allows for long-term outdoor use.

5. Decoration and furniture industry: Used for interior partition keels, display rack frames, or load-bearing structures of custom furniture, it combines practicality and lightweight advantages and is suitable for a variety of design styles.

PACKAGING AND SHIPPING

1. Wrapping: Wrap the upper and lower ends and the middle of the channel steel with canvas, plastic sheet and other materials, and achieve packaging through bundling. This packaging method is suitable for a single piece or a small amount of channel steel to prevent scratches, damage and other situations.

2. Pallet packaging: Place the channel steel flat on the pallet, and fix it with strapping tape or plastic film, which can reduce the workload of transportation and facilitate handling. This packaging method is suitable for the packaging of large quantities of channel steel.

3. Iron packaging: Put the channel steel into the iron box, and then seal it with iron, and fix it with a binding tape or plastic film. This way can better protect the channel steel and is suitable for long-term storage of the channel steel.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

FAQ

Q: Are u a manufacturer?

A: Yes, we are a manufacturer. We have our own factory located in Tianjin City, China.

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years gold supplier and accept trade assurance.