Download the Latest W beam Specifications and Dimensions.

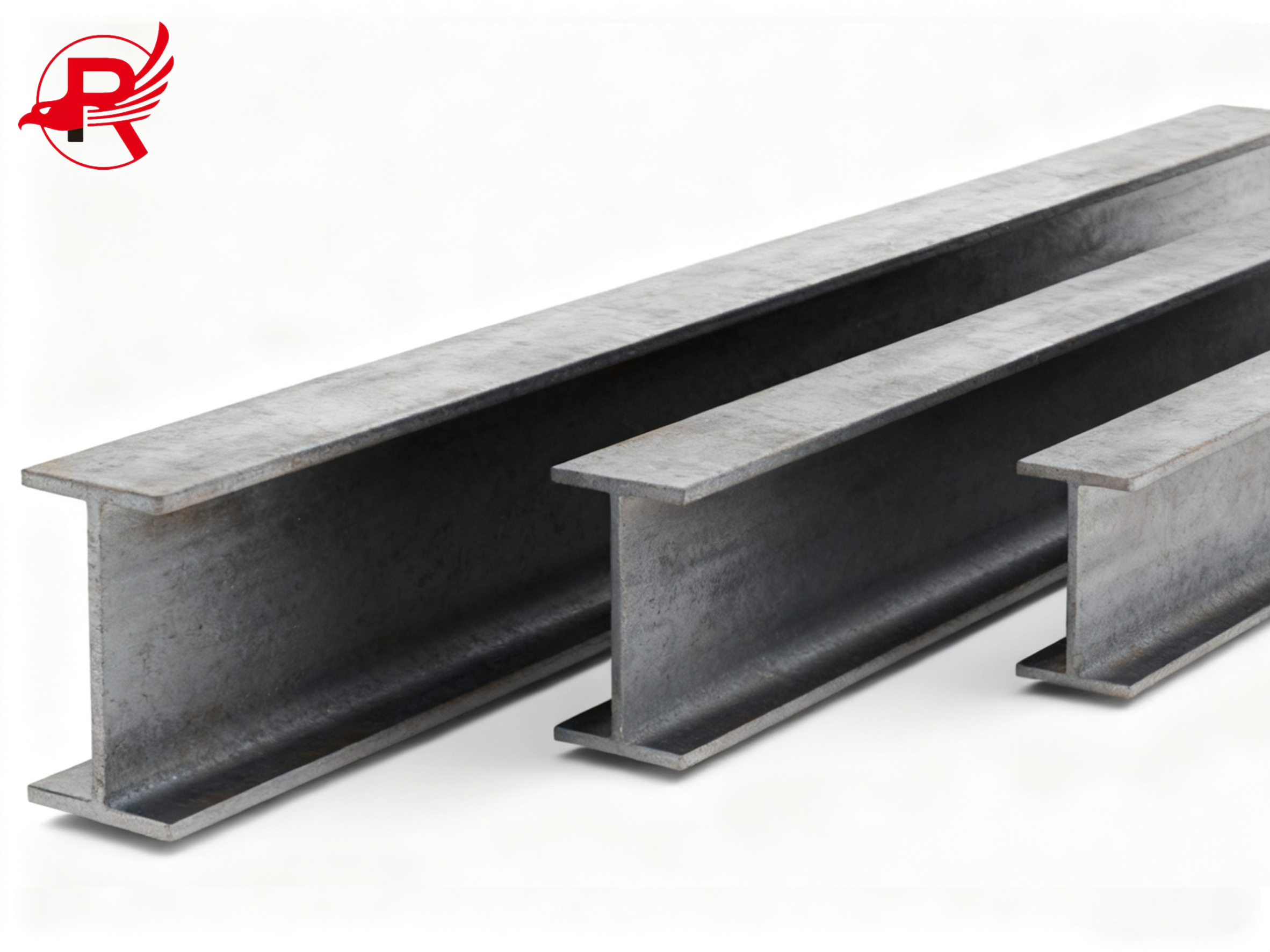

Customized Hot Rolled Steel H Beam ASTM A36/A572/A992 Standards Structural Steel Beams for Construction

| Material Standard | A36/A992/A572 Grade 50 | Yield Strength | ≥345MPa |

| Dimensions | W6×9, W8×10, W12×30, W14×43, etc. | Length | Stock for 6 m & 12 m, Customized Length |

| Dimensional Tolerance | Conforms to GB/T 11263 or ASTM A6 | Quality Certification | ISO 9001, SGS/BV Third-Party Inspection Report |

| Surface Finish | Hot-dip galvanizing, paint, etc. Customizable | Applications | Industrial plants, warehouses, commercial buildings, residential buildings, bridges |

Technical Data

ASTM A36/ASTM A992/ASTM A572 W-beam (or H-beam) Chemical Composition

| Steel grade | Carbon, | Manganese, | Phosphorus, | Sulfur, | Silicon, | |

| max,% | % | max,% | max,% | % | ||

| A36 | 0.26 | -- | 0.04 | 0.05 | ≤0.40 | |

| NOTE:Copper content is available when your order is specified. | ||||||

| Steel Grade | Carbon, max, % |

Manganese, % |

Silicon, max, % |

Vanadium, max, % |

Columbium, max, % |

Phosphorus, max, % |

Sulfur, max, % |

|

| ASTMA992 | 0.23 | 0.50 - 1.60 | 0.40 | 0.15 | 0.05 | 0.035 | 0.045 | |

| Item | Grade | Carbon,max, % |

Manganese,max, % |

Silicon,max, % |

Phosphorusmax, % |

Sulfur,max, % |

|

| A572 steel beams | 42 | 0.21 | 1.35 | 0.40 | 0.04 | 0.05 | |

| 50 | 0.23 | 1.35 | 0.40 | 0.04 | 0.05 | ||

| 55 | 0.25 | 1.35 | 0.40 | 0.04 | 0.05 | ||

ASTM A36/A992/A572 W-beam (or H-beam) Mechanical Property

| Steel Grade | Tensile strength, ksi[MPa] |

Yield pointmin, ksi[MPa] |

Elongation in 8 in.[200 mm],min,% |

Elongation in 2 in.[50 mm],min,% |

|

| A36 | 58-80 [400-550] | 36[250] | 20.00 | 21 | |

| Steel Grade | Tensile strength, ksi | Yield point, min, ksi | |

| ASTM A992 | 65 | 65 | |

| Item | Grade | Yield pointmin,ksi[MPa] | Tensile strength,min,ksi[MPa] | |

| A572 steel beams | 42 | 42[290] | 60[415] | |

| 50 | 50[345] | 65[450] | ||

| 55 | 55[380] | 70[485] | ||

ASTM A36 / A992 / A572 Wide Flange H-beam Sizes - W Beam

| Designation | Dimensions | Static Parameters | |||||||

| Moment of Inertia | Section Modulus | ||||||||

| Imperial(in x lb/ft) | Depthh (in) | Widthw (in) | Web Thicknesss (in) | Sectional Area(in2) | Weight(lb/ft) | Ix(in4) | Iy(in4) | Wx(in3) | Wy(in3) |

| W 27 x 178 | 27.8 | 14.09 | 0.725 | 52.3 | 178 | 6990 | 555 | 502 | 78.8 |

| W 27 x 161 | 27.6 | 14.02 | 0.660 | 47.4 | 161 | 6280 | 497 | 455 | 70.9 |

| W 27 x 146 | 27.4 | 14 | 0.605 | 42.9 | 146 | 5630 | 443 | 411 | 63.5 |

| W 27 x 114 | 27.3 | 10.07 | 0.570 | 33.5 | 114 | 4090 | 159 | 299 | 31.5 |

| W 27 x 102 | 27.1 | 10.02 | 0.515 | 30.0 | 102 | 3620 | 139 | 267 | 27.8 |

| W 27 x 94 | 26.9 | 10 | 0.490 | 27.7 | 94 | 3270 | 124 | 243 | 24.8 |

| W 27 x 84 | 26.7 | 9.96 | 0.460 | 24.8 | 84 | 2850 | 106 | 213 | 21.2 |

| W 24 x 162 | 25 | 13 | 0.705 | 47.7 | 162 | 5170 | 443 | 414 | 68.4 |

| W 24 x 146 | 24.7 | 12.9 | 0.650 | 43.0 | 146 | 4580 | 391 | 371 | 60.5 |

| W 24 x 131 | 24.5 | 12.9 | 0.605 | 38.5 | 131 | 4020 | 340 | 329 | 53.0 |

| W 24 x 117 | 24.3 | 12.8 | 0.55 | 34.4 | 117 | 3540 | 297 | 291 | 46.5 |

| W 24 x 104 | 24.1 | 12.75 | 0.500 | 30.6 | 104 | 3100 | 259 | 258 | 40.7 |

| W 24 x 94 | 24.1 | 9.07 | 0.515 | 27.7 | 94 | 2700 | 109 | 222 | 24.0 |

| W 24 x 84 | 24.1 | 9.02 | 0.470 | 24.7 | 84 | 2370 | 94.4 | 196 | 20.9 |

| W 24 x 76 | 23.9 | 9 | 0.440 | 22.4 | 76 | 2100 | 82.5 | 176 | 18.4 |

| W 24 x 68 | 23.7 | 8.97 | 0.415 | 20.1 | 68 | 1830 | 70.4 | 154 | 15.7 |

| W 24 x 62 | 23.7 | 7.04 | 0.430 | 18.2 | 62 | 1550 | 34.5 | 131 | 9.8 |

| W 24 x 55 | 23.6 | 7.01 | 0.395 | 16.2 | 55 | 1350 | 29.1 | 114 | 8.3 |

| W 21 x 147 | 22.1 | 12.51 | 0.720 | 43.2 | 147 | 3630 | 376 | 329 | 60.1 |

| W 21 x 132 | 21.8 | 12.44 | 0.650 | 38.8 | 132 | 3220 | 333 | 295 | 53.5 |

| W 21 x 122 | 21.7 | 12.39 | 0.600 | 35.9 | 122 | 2960 | 305 | 273 | 49.2 |

| W 21 x 111 | 21.5 | 12.34 | 0.550 | 32.7 | 111 | 2670 | 274 | 249 | 44.5 |

| W 21 x 101 | 21.4 | 12.29 | 0.500 | 29.8 | 101 | 2420 | 248 | 227 | 40.3 |

| W 21 x 93 | 21.6 | 8.42 | 0.580 | 27.3 | 93 | 2070 | 92.9 | 192 | 22.1 |

| W 21 x 83 | 21.4 | 8.36 | 0.515 | 24.3 | 83 | 1830 | 81.4 | 171 | 19.5 |

| W 21 x 73 | 21.2 | 8.3 | 0.455 | 21.5 | 73 | 1600 | 70.6 | 151 | 17.0 |

| W 21 x 68 | 21.1 | 8.27 | 0.430 | 20.0 | 68 | 1480 | 64.7 | 140 | 15.7 |

| W 21 x 62 | 21 | 8.24 | 0.400 | 18.3 | 62 | 1330 | 57.5 | 127 | 13.9 |

| W 21 x 57 | 21.1 | 6.56 | 0.405 | 16.7 | 57 | 1170 | 30.6 | 111 | 9.4 |

| W 21 x 50 | 20.8 | 6.53 | 0.380 | 14.7 | 50 | 984 | 24.9 | 94.5 | 7.6 |

| W 21 x 44 | 20.7 | 6.5 | 0.350 | 13.0 | 44 | 843 | 20.7 | 81.6 | 6.4 |

Click the Button on The Right

Ordinary Surface

Galvanized Surface (hot-dip galvanizing thickness ≥ 85μm, service life up to 15-20 years),

Black Oil Surface

Construction Steelwork: Frame beams and columns for high rise office, residential, mall and other buildings; main structures and crane beams for industrial plants.

Bridge Engineering: Deck systems and substructures for small and medium highway and railway bridges.

City and special engineering: Including subway stations, urban pipeline corridor supports, tower crane foundations and temporary construction supports.

International Engineering: Our products are designed in accordance with North American and other internationally recognised steel structure design standards.

1) Branch Office - Support in Spanish, help with customs clearance, etc.

2) About 5,000 tons of stock in stock, with a wide variety of sizes

3) Checked by the authoritative bodies like CCIC, SGS, BV, TUV with standard seaworthy packaging.

Protective Packaging:

Each bundle is securely wrapped with heavy-duty tarpaulin. To prevent moisture damage, 2–3 desiccant bags are placed inside every bundle, followed by an outer layer of heat-sealed waterproof covering.

Bundling Method:

Bundles are fastened using 12–16 mm diameter steel straps, designed to meet lifting and handling requirements at U.S. ports, with an average bundle weight of 2–3 tons.

Regulatory Labeling:

Clear bilingual labels (English & Spanish) are attached to each bundle, displaying key information including material grade, specifications, HS code, batch number, and corresponding test report reference.

Oversized H-Beam Handling:

For large H-section steel with a section height of 800 mm or above, the surface is treated with industrial-grade anti-rust oil, air-dried, and then fully covered with tarpaulin for enhanced corrosion protection.

Logistics Support:

We operate an efficient logistics network supported by long-term partnerships with major shipping lines such as Maersk (MSK), MSC, and COSCO, ensuring reliable and timely delivery.

Quality Assurance:

All packaging and transportation processes strictly follow the ISO 9001 quality management system, with comprehensive controls covering packaging materials, handling methods, and transport arrangements. This guarantees H-beams remain in optimal condition from production to final delivery, supporting smooth and uninterrupted project execution.

Q: What are the standards for your H Beam steel for central America markets?

A: Our H Beams are produced to ASTM A36 and ASTM A572 Grade 50, which are widely accepted grades across Central America. We can also provide goods in line with local regulations like the NOM requirements for Mexico, etc, upon clients' request.

Q: How long is the delivery time to Panama?

A: Ocean shipping take 28-32 days from Tianjin Port to Colon Free Zone. The total lead-time is about 45-60 days including production and customs procedures. For faster delivery service, please contact us immediately to discuss further the details of your order.

Q: Do you provide the service of customs clearance?

A: Yes. We have partnered with reputable customs brokers in Central America to facilitate the process of submission for import declarations, duty and other formalities to make a seamless and finished delivery.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506