Custom Prefabricated Modular Steel Structure Building ASTM A36 Standard with Galvanized Surface Treatment

APPLICATION

Steel Frame Construction: Utilizes the high-strength steel, solid, lasting, earthquake and wind proof, quick construction, flexible indoors.

Steel Structure House: Energy Saving and Environmental Protection in Lightweight Steel Frame and an Efficient Process of Construction.

Steel Structure Warehouse: High bay steel warehouse building structrure for two floor with shelf storage warehouse building.

Steel Structure Factory Building: Open structure, large depth and robust steel construction make it ideal for multitude of manufacturing.

PRODUCT DETAIL

Core steel structure products for factory construction

1. Main load-bearing structure (adaptable to tropical seismic requirements)

| Product Type | Specification Range | Core Function | Central America Adaptation Points |

|---|---|---|---|

| Portal Frame Beam | W12×30 ~ W16×45 (ASTM A572 Gr.50) | Main roof and wall load-bearing beam | Seismic resistant bolted joints and section optimized for weight reduction and easy transportation. |

| Steel Column | H300×300 ~ H500×500 (ASTM A36) | Supports floors and frame | Inserts Seismic connectors, hot-dip galvanized (zinc layer min. 85 μm) for humid conditions. |

| Crane Beam | W24×76 ~ W30×99 (ASTM A572 Gr.60) | Load-bearing beam for cranes | High capacity design (5–20t hoists), end beams fitted with shear plates |

2. Enclosure system products (weatherproof + anti-corrosion)

Roof Purlins: From C12×20 to C16×31, hot dip galvanized, at a distance of 1.5-2m. They are excellent for color coated steel panels and typhoon resistance of 12 level.

Wall Purlins: Z10×20 to Z14×26 with anti-rusting paint (dried salt spray over 1000 hours) - also has ventilation holes to ventilate the tropical factory moisture-condit.

Support System: Galvanized round steel Φ12~Φ16 and angle (L50×5 steel angle) for bracing strengthens the sideway stability against the wind force of hurricane).

3. Supporting auxiliary products (localized construction adaptation)

Precast component:Hot-dip galvanized steel plate (thickness: 10–20 mm) for concrete footing, commercially available in Costa Rica, imported into other Central American countries.

Bolts:High strength bolts (grade 8.8, hot dip galvanized) are used in place of welding at the job site, minimizing the erection time.

Fire & Corrosion Protection: Water based intumescent coating (≥1.5 h fire protection), UV resistant acrylic anti-corrosive coating (≥10 years service life), meeting local environmental regulations.

STEEL STRUCTURE PROCESSING

| Processing Method | Machines Used | Description |

|---|---|---|

| Cutting | CNC plasma/flame cutters, shears | Plasma, flame cutting for steel plates/sections, shearing for thin plates with accurate size. |

| Forming | Cold bending machine, press brake, rolling machine | Cold bending for C/Z purlins, gutters, edge trims rolling for round support bars. |

| Welding | Submerged arc, manual arc, CO₂ welders | Submerged arc welding for H-columns/beams; manual welding for gusset plates; CO₂ welding for thin sections. |

| Holemaking | CNC drilling, punching machines | Bolt hole drilling with CNC; punching small batches with exact size and position. |

| Surface Treatment | Shot/sand blasting machines, grinder, galvanizing line | Rust removal, welding grinding, hot-dip galvanizing for bolts and structural supports. |

| Assembly | Assembly platforms, measuring tools | Columns, beams and bracings pre-assembled; taken apart after dimensional checks. |

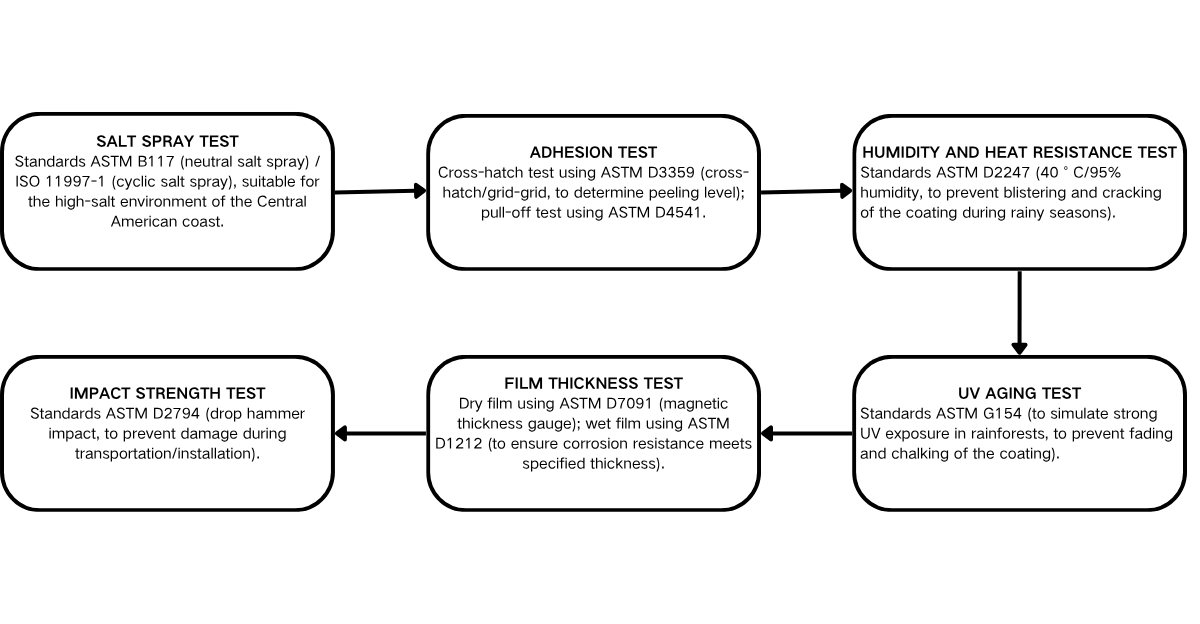

STEEL STRUCTURE TESTING

SURFACE TREATMENT

Epoxy zinc-rich coating

Hot-dip galvanized (≥85 μm, 15–20 years lifespan)

Black oil coating

PACKAGING AND SHIPPING

Packaging:

The steel is well packed with surface protection and stiffness maintaining agent for handling.

Small accessories are packaged in wooden boxes, with waterproof wrapping, plastic or rust-proof paper.

Boxes and bundles are labelled clearly so that they may be safely unloaded and efficiently installed.

Transportation:

Container or bulk vessel shipping depending on load size and destination.

Bulky or heavy goods are restrained from moving using steel strapping and wood blocks.

All delivery conform to international transport regulations for delivery security and reliability.

WHY CHOOSE OUR STEEL STRUCTURES?

Clear Span Design: Maximize your internal workspace with unobstructed layouts (up to 30m+ without interior columns).

Low Maintenance: Our hot-dip galvanizing process ensures maximum protection against rust and corrosion in harsh environments.

Turnkey Solution: From initial 3D CAD drawings to shipping and installation guidance, we provide a seamless one-stop service.

Eco-Friendly: Steel is 100% recyclable, making it the preferred choice for modern green construction.

Ready to start your project? Click "Contact US" to get a FREE 3D Design and Quote within 24 hours!

FAQ

Q1: Could you design for my local wind/snow load requirements?

A1: Yes, the load will be calculated based on your local climate data by our engineer with professional software (PKPM, Tekla, AutoCAD).

Q2: How long is delivery time?

A2: Normally 15-21 days according to the complexity and quantity of the order.

Q3: Will you install it?

A3: We have very detailed installation drawings and video tutorials. we can dispatch supervisors or teams for large projects abroad to oversee or carry out installation.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506