Customized Pre-Engineerd Prefabricated Steel Structure Building School/Hotel for Construction

Steel structures are designed individually according to the client's architectural and structural requirements, then assembled in a rational sequence. Due to the material's advantages and flexibility, steel structures are widely used in medium-sized and large-scale projects (e.g., prefabricated steel structures).

Steel structures also include secondary structures and other steel components of buildings. Each steel structure has a characteristic shape and chemical composition to meet the requirements of the project.

Steel is primarily composed of iron and carbon. Manganese, alloys, and other chemical components are also added to enhance strength and durability.

Depending on the specific requirements of each project, steel components can be formed by hot or cold rolling or welded from thin or bent plates.

Steel structures come in a variety of shapes, sizes, and specifications. Common shapes include beams, channels, and angles.

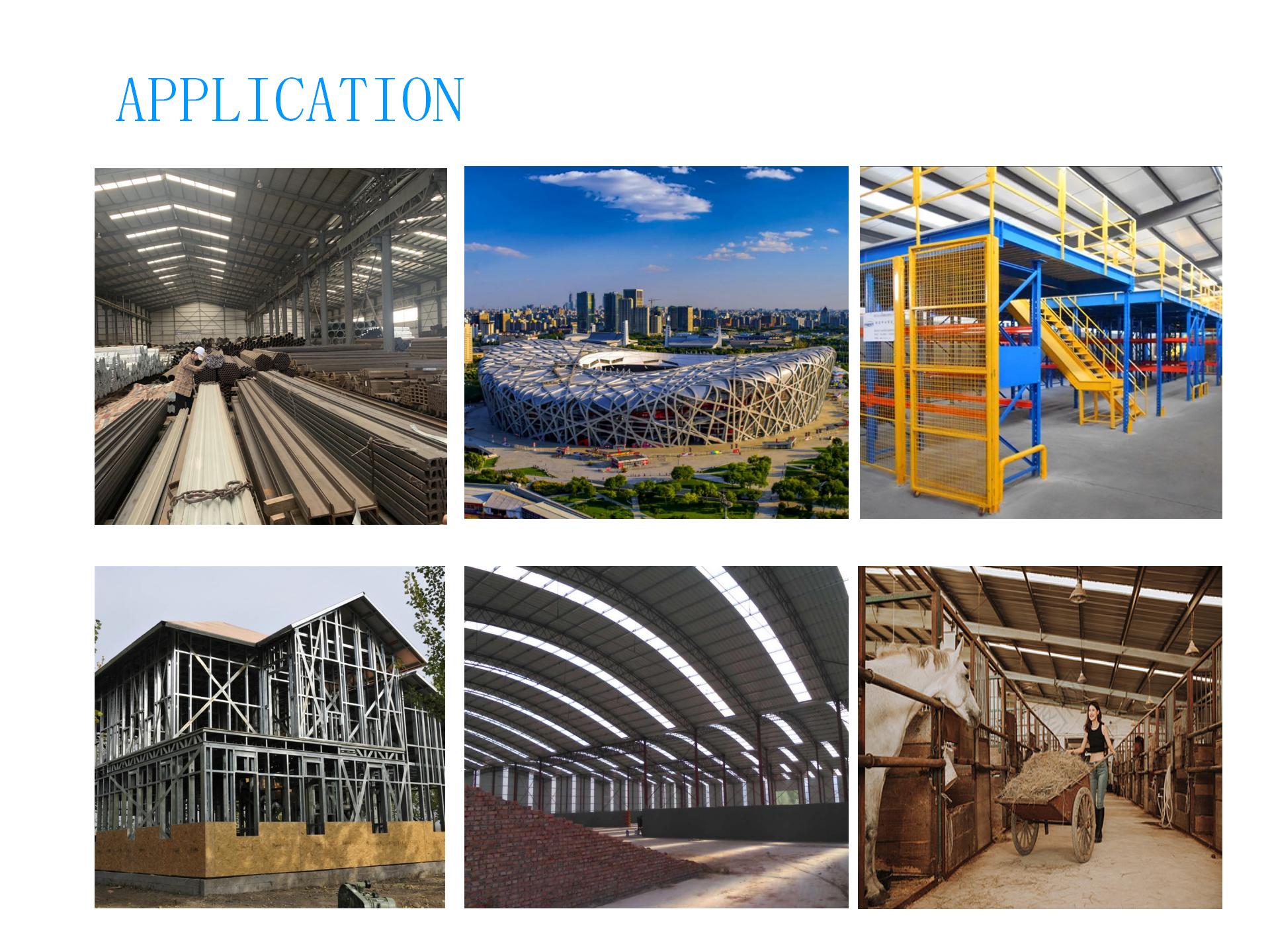

Application:

Steel Structure are widely used in various building types and engineering projects, including but not limited to the following aspects:

Steel structures are widely used across various building types and engineering projects due to their strength, flexibility, and efficiency:

-

Commercial Buildings: Offices, shopping malls, and hotels benefit from large spans and flexible layouts.

-

Industrial Plants: Factories, warehouses, and workshops gain from high load-bearing capacity and rapid construction.

-

Bridges: Highway, railway, and urban transit bridges utilize steel for lightweight, long spans, and fast assembly.

-

Sports Venues: Stadiums, gyms, and swimming pools enjoy wide, column-free spaces.

-

Aerospace Facilities: Airports and aircraft hangars benefit from large spans and excellent seismic performance.

-

High-Rise Buildings: Residential and office towers leverage lightweight structures and superior seismic resistance.

| Product name: | Steel Building Metal Structure |

| Material : | Q235B ,Q345B |

| Main frame : | I-beam,H-beam,Z-beam,C-beam,Tube,Angle,Channel,T-beam,Track section,Bar,Rod,Plate,Hollow beam |

| Main structural types: | Truss structure,Frame structure,Grid structure,Arch structure,Prestressed structure,Girder bridge,Truss bridge,Arch bridge,Cable bridge,Suspension bridge |

| Roof and wall : | 1.corrugated steel sheet ;

2.rock wool sandwich panels ;

3.EPS sandwich panels ; 4.glass wool sandwich panels |

| Door: | 1.Rolling gate

2.Sliding door

|

| Window: | PVC steel or aluminum alloy |

| Down spout : | Round pvc pipe |

| Application : | All kinds of industrial workshop ,warehouse ,high-rise building,Light Steel Structure House,Steel Structure School Building,Steel Structure Warehouse,Prefab Steel Structure House,Steel Structure Shed,Steel Structure Car Garage,Steel Structure For Workshop |

PRODUCT PRODUCTION PROCESS

ADVANTAGE

What precautions should be taken when building a steel-framed house?

1. Ensure Structural Stability

The rafter layout of a steel-framed house should be coordinated with the design and finishing methods of the attic. During construction, avoid secondary damage to the steel to prevent safety hazards.

2. Pay Attention to Steel Selection

There are many types of steel available on the market, but not all are suitable for building. To ensure structural stability, it is recommended to avoid hollow steel pipes and avoid painting the interior directly, as hollow steel pipes are prone to rust.

3. Ensure a Clear Structural Layout

Steel structures vibrate violently when subjected to stress. Therefore, precise analysis and calculations must be performed during construction to minimize vibration and ensure a beautiful and sturdy appearance.

4. Pay Attention to Painting

After the steel structure is fully welded, the surface should be coated with anti-rust paint to prevent rust caused by external factors. Rust not only affects the decorative effect of the walls and ceilings but can also pose a safety hazard.

DEPOSIT

The construction of a steel structure factory building is primarily divided into five parts:

1. Embedded components (which stabilize the factory structure)

2. Columns are typically constructed of H-shaped steel or C-shaped steel (typically two C-shaped steels are connected by angle steel).

3. Beams are typically constructed of C-shaped steel or H-shaped steel (the height of the center section is determined by the span of the beam).

4. Rods, typically C-shaped steel, but can also be channel steel.

5. There are two types of tiles. The first is single-piece tiles (colored steel tiles). The second is composite panels (polystyrene, rock wool, polyurethane). (Foam is sandwiched between the two layers of tiles, providing warmth in winter and coolness in summer, while also providing sound insulation.)

PRODUCT INSPECTION

Inspection of prefabricated steel structures are mainly on raw material and primary structure. Raw Typical raw materials inspected are bolts, steel, and coatings. For the main structure, defect detection of weld and load testing are also conducted.

Inspection Range:

Applicable to the steel and welding materials, the normal fasteners, the welds, the sealing plates, the bolts, the cone heads and sleeves, the coating materials, the welding projects (roof welding and bolting are included in the scope of this project), standard fasteners, high strength bolt torque, component size, stage, pre-install installation dimension, single stage/mutli-stage/high rise/steel grid single surface, double surface panels and lining panels construction, and covering thickness.

Checked of:

The following are among these appearance, non destructive tests, tensile tests, impact tests, bend tests, metallographic structure, pressure containing devices, chemical make up, weld quality, worsen inside and outside of your weld, weld mechanical attributes, coating adhesion thickness, surface quality, consistency, flexural strength, resistance to rust and blunt, resistance to spontaneous events, reaction to impacts, reaction to stressing, reaction to chemical dealing with, resistance to moisture and temperature, reaction to Temperature cycling, resistance to chlorides, cathodic disbonding resistance, ultrasonic and magnetic particle testing, bolting torque and strength, structural verticality, real world weights, power, toughness, and holistic reliability.

PROJECT

Our company often exports Steel Structure Workshop products to the Americas and Southeast Asian countries. We participated in one of the projects in the Americas with a total area of approximately 543,000 square meters and a total use of approximately 20,000 tons of steel. After the project is completed, it will become a steel structure complex integrating production, living, office, education and tourism.

Whether you are looking for a contractor, a partner, or want to learn more about steel structures, please feel free to contact us to discuss further. We undertake a variety of light and heavy steel structure buildings, and we accept custom steel structure designs.We can also provide the steel structure materials you need.We will help you quickly resolve your project issues.

*Send the email to [email protected] to get a quotation for your projects

APPLICATION

Cost Efficiency: The manufacture and maintenance of steel structures is less expensive, and with up to 98% of components being reused without any diminishing of strength.

Quick fit: Accurate parts are easier to put together, assisted by management software to organize the building process.

Safety & Health: On-site smoke and dust generation is minimized due to safe installation of components, fabricated in a controlled environment. On this account, steel structure is considered among the safest building solutions.

Versatility: Building for the future is simple with our flexible design solutions. You can easily modify or extend your building to accommodate future loads or design requirements that would be impossible to meet in any other type of building.

PACKAGING AND SHIPPING

Packing: According to your requirements or the most suitable.

Shipping:

Transportation: Select flatbed trucks, containers, or ships based on the steel structure’s weight, quantity, distance, cost, and regulations.

Lifting: Use cranes, forklifts, or loaders with adequate capacity to safely load and unload the steel components.

Load Securing: Properly strap and brace all packaged steel to prevent movement, sliding, or damage during transit.

COMPANY STRENGTH

Made in China - High Quality, Efficient Service, Favorable Credit Rating

Scale Advantage: Large Factory and Large Supply Chain to Have Efficient Production and Integrated Service.

Product Variety: Extensive portfolio of steel products including steel structures, rails, sheet piles, solar brackets, channels, silicon steel coils for various applications.

Steady Supply: Reliable production for constant delivery, useful for large amount orders.

Excellent Brand: Well acknowledging brand in this line of products.

Integrated Service: One-stop service including customization, production and transportation.

Affordable Price:The good price for good steel.

*Send the email to [email protected] to get a quotation for your projects

COMPANY STRENGTH

CUSTOMERS VISIT