Discount Hot Rolled U Shaped Carbon Plate Steel Sheet Pile Wholesale Type II Type III Steel Sheet Piles

|

Product Name

|

|

|

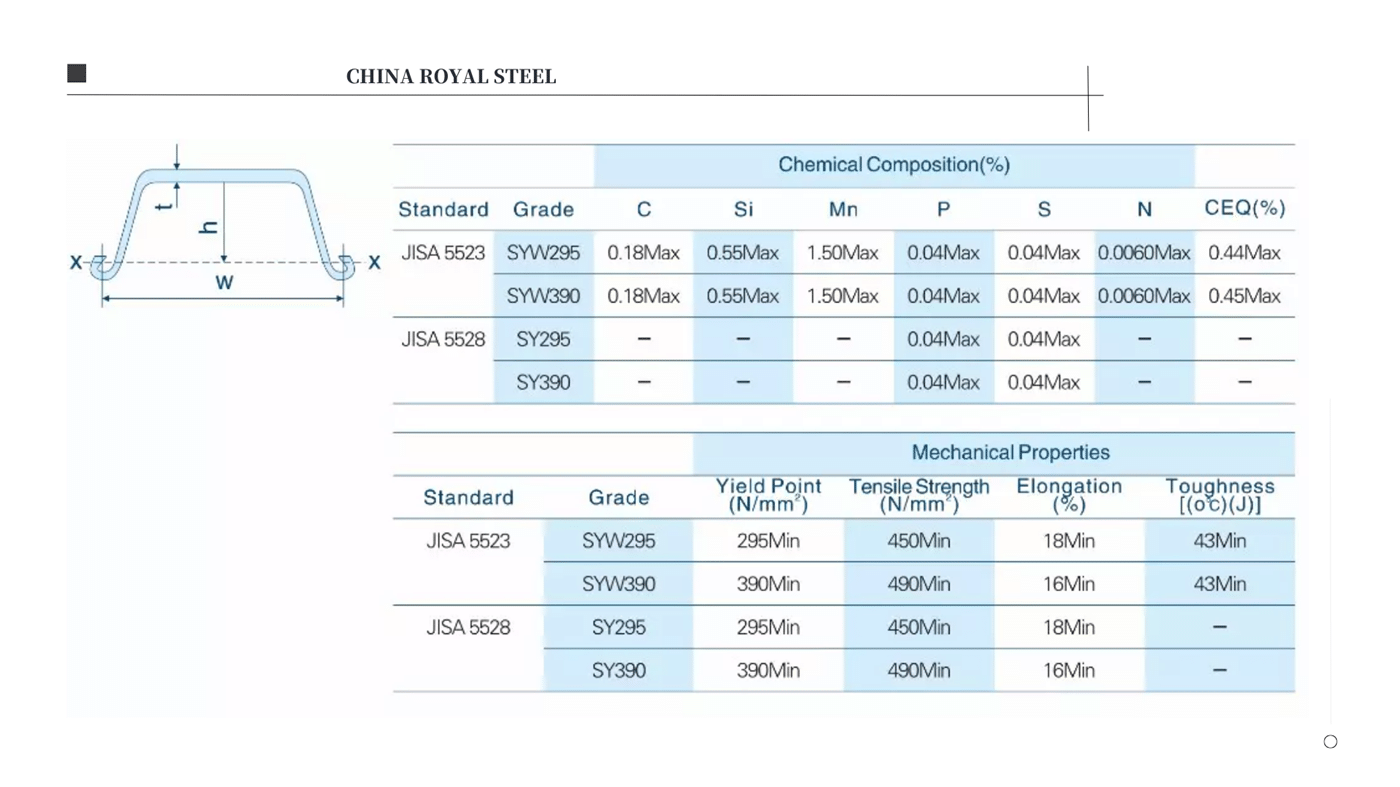

Steel Grade

|

Q345,Q345b,S275,S355,S390,S430,SY295,SY390,ASTM A690

|

|

Production standard

|

EN10248,EN10249,JIS5528,JIS5523,ASTM

|

|

Delivery time

|

One week,80000 tons in stock

|

|

Certificates

|

ISO9001,ISO14001,ISO18001,CE FPC

|

|

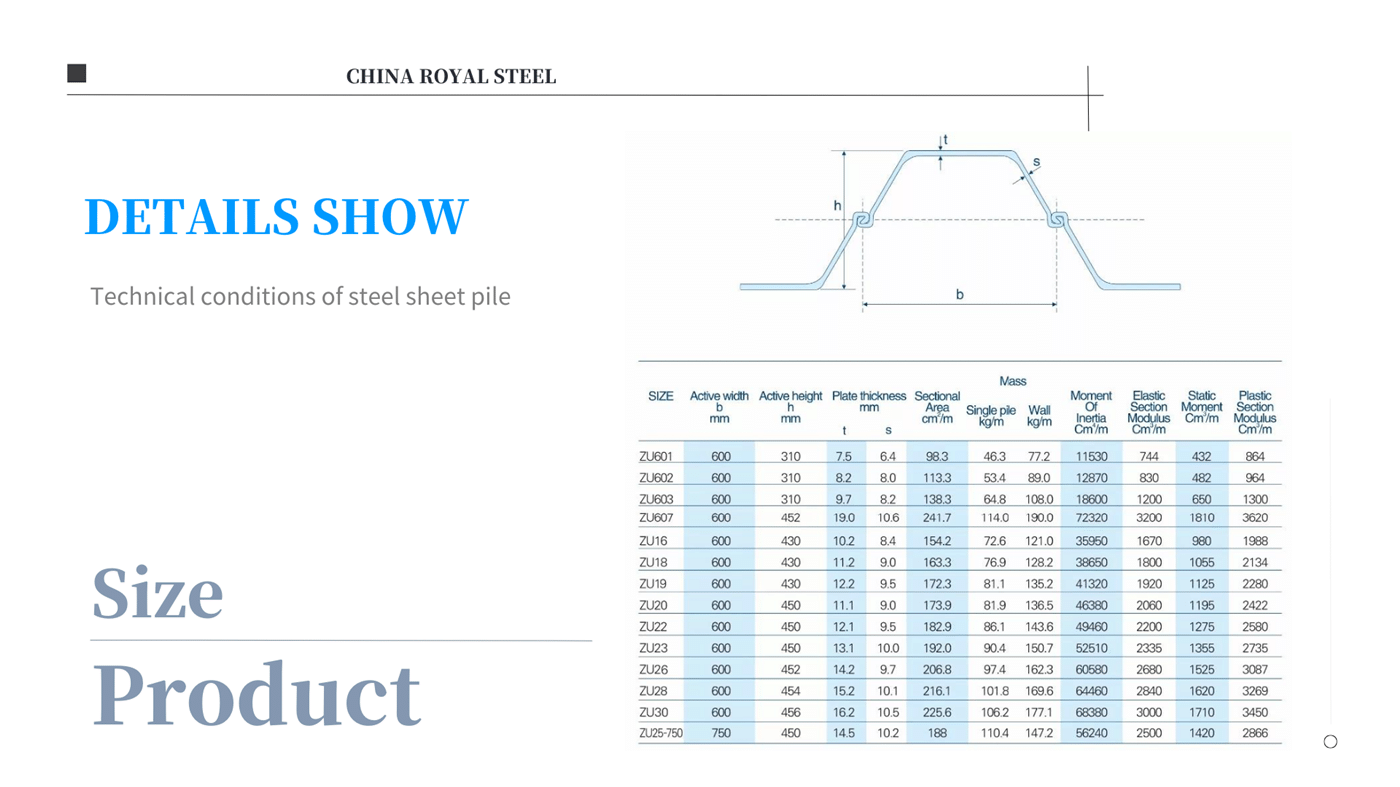

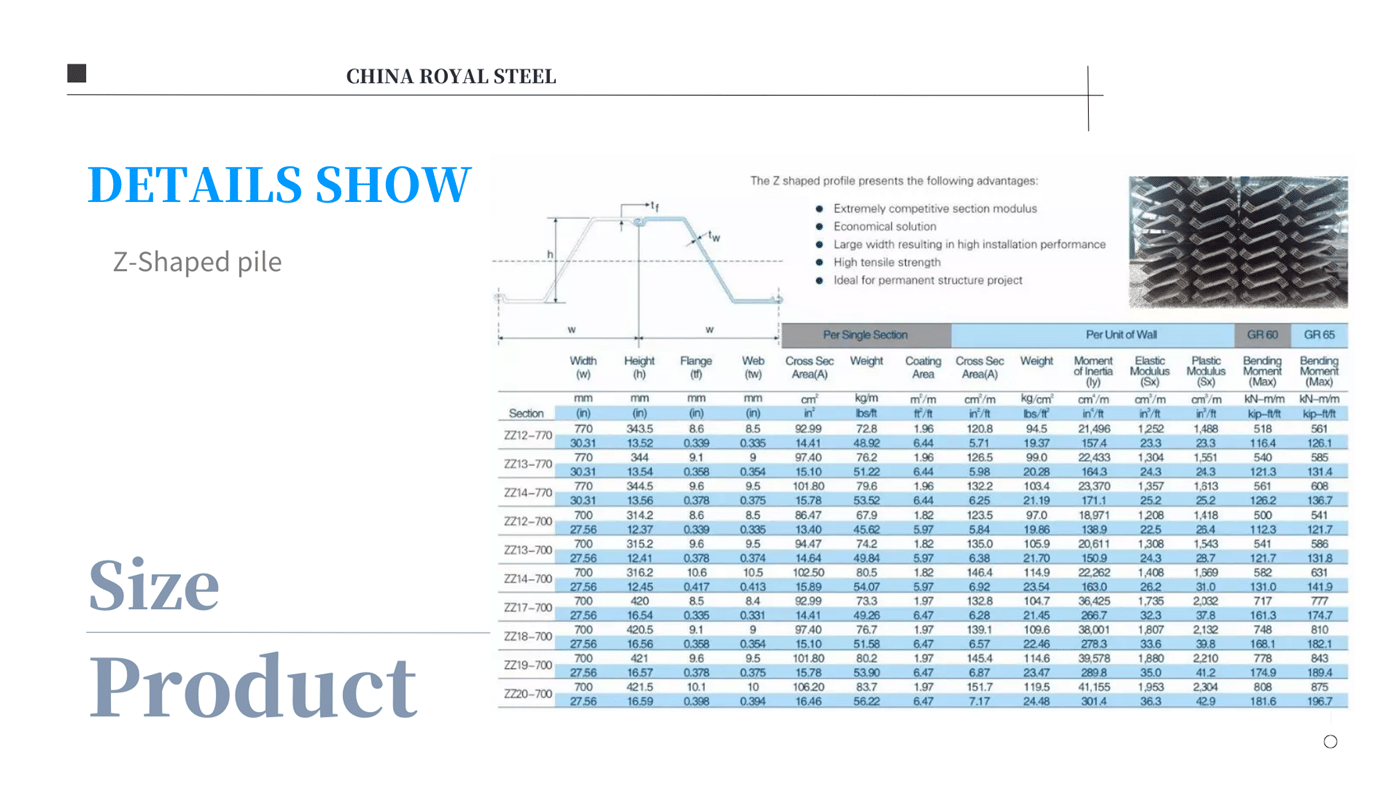

Dimensions

|

Any dimensions,any width x height x thickness

|

|

Length

|

Single length up to over 80m

|

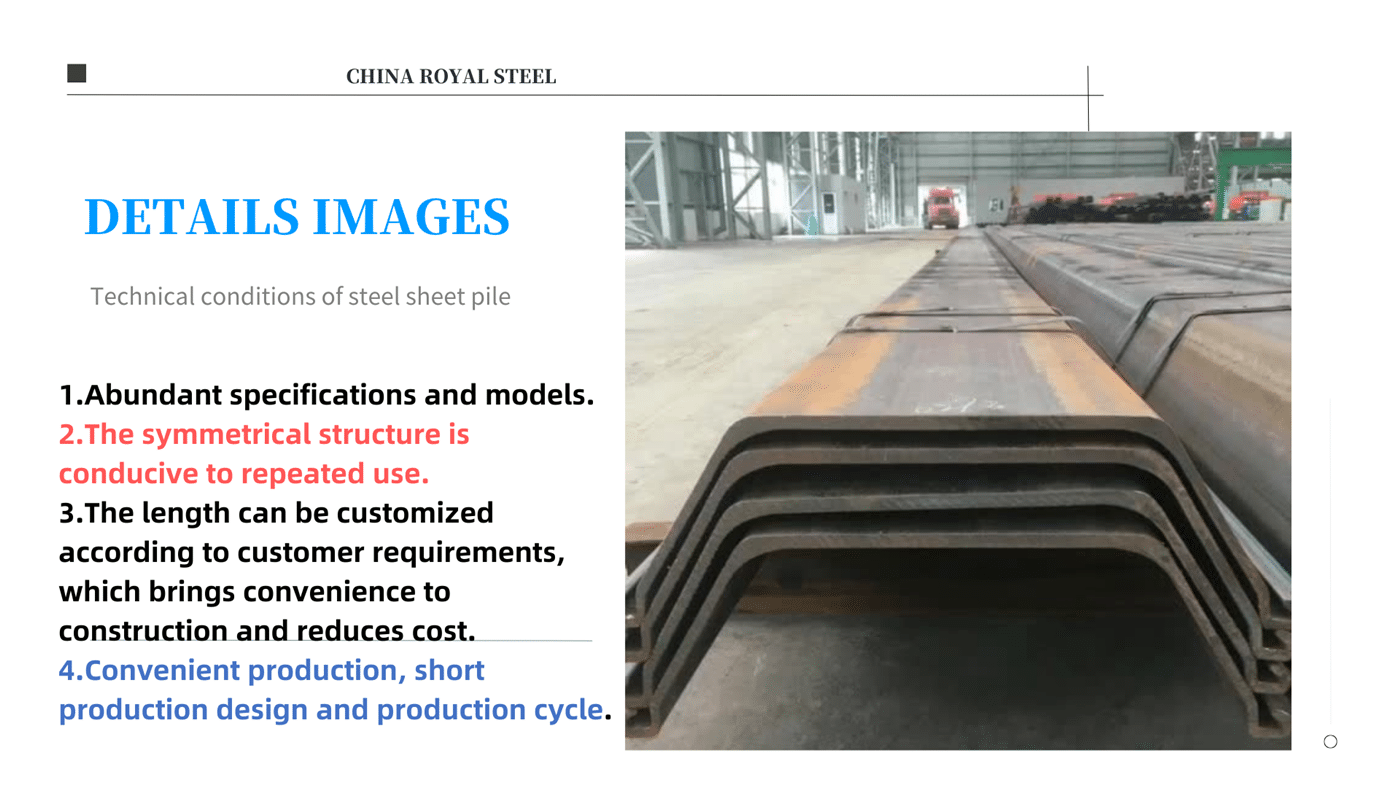

1. We can produce all types of sheet piles,pipe piles and accessories,we can adjust our machines to produce in any width x height x thickness .

2. We can produce single length up to over 100m,and we can do all painting,cutting,welding etc fabrications in factory .

3. Fully internationally certified:ISO9001,ISO14001,ISO18001,CE,SGS,BV etc..

Features

Understanding Steel Sheet Piles

Steel sheet piles are long, interlocking steel sections driven into the ground to form a continuous wall. They are commonly used in projects that retain soil or water, such as foundation construction, underground parking garages, waterfront buildings, and ship bulkheads. Two common types of steel sheet piles are cold-formed steel and hot-rolled steel, each offering unique advantages in different applications.

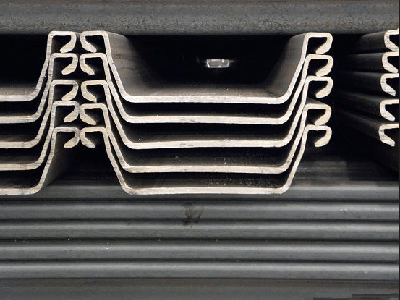

1. Cold-Formed Sheet Piles: Versatility and Cost-Effectiveness

Cold-bending process, flexible cross-section, low cost, weak rigidity, suitable for small and medium-sized temporary projects (such as municipal pipeline foundation pits, small cofferdams), mostly for temporary soil and water retaining;

2. Hot-Rolled Steel Sheet Piles: Unmatched Strength and Durability

Made by high temperature rolling, it has stable cross-section, tight locking, strong rigidity and load resistance. It is suitable for deep foundation pits and permanent projects (such as port terminals and flood embankments). It has a long service life and high reliability.

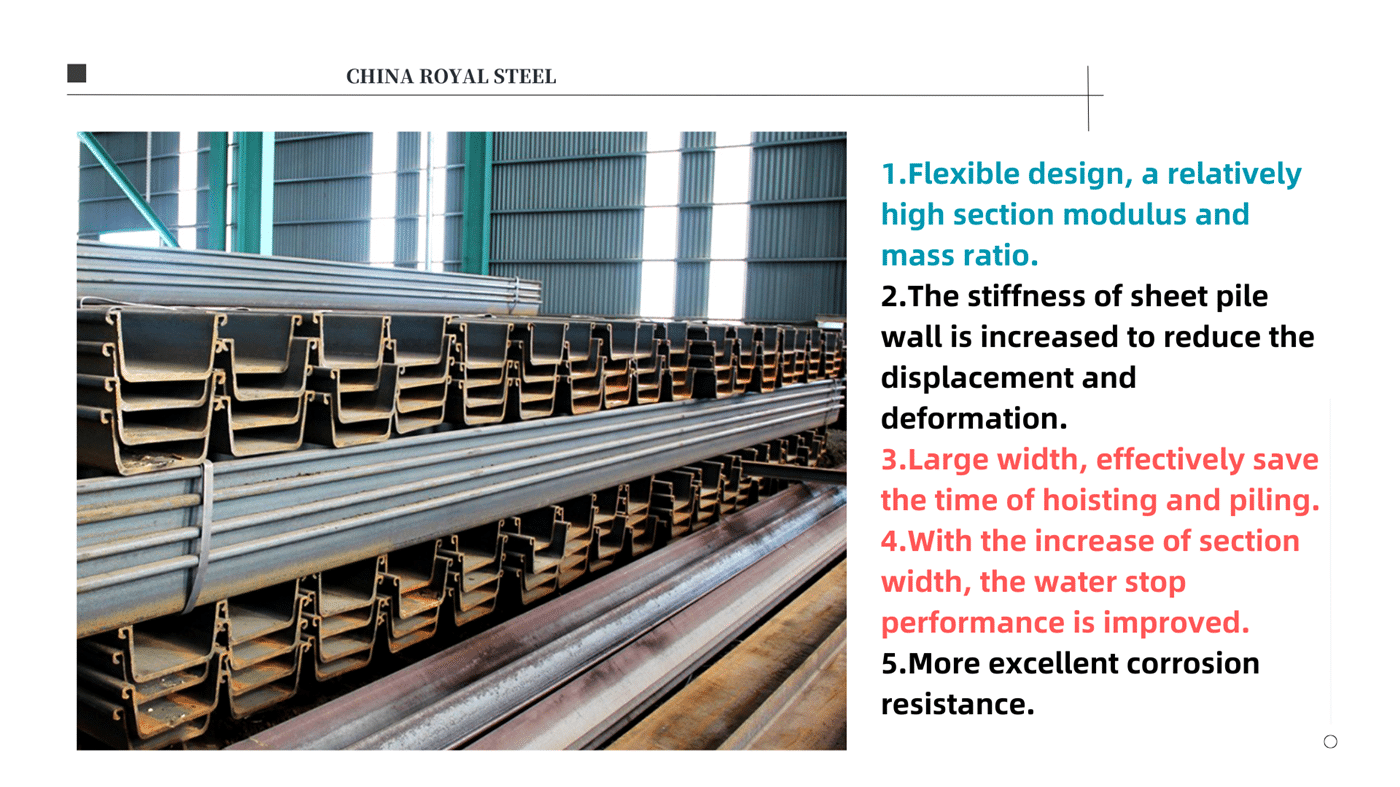

Benefits of Steel Sheet Pile Walls

Steel sheet pile walls offer numerous benefits that make them an attractive choice for construction projects:

1. Fast Construction: Interlocking design enables quick assembly into continuous walls; no complex foundation work, cutting project timelines.

2. Dual Functionality: Simultaneously retains soil and blocks water, suitable for both earth-retaining and anti-seepage scenarios (e.g., excavations, waterfronts).

3. Reusability: High-strength steel material allows repeated recovery and reuse in multiple projects, reducing material waste and costs.

4. Space Efficiency: Compact wall structure minimizes occupied area, ideal for narrow construction sites (e.g., urban underground projects).

5. Strong Durability: Steel (with optional galvanization) resists corrosion; hot-rolled types offer long service life for permanent structures.

6. Flexible Adaptability: Various lengths/specifications available to match different soil conditions and depth requirements (temporary or permanent).

Application

Hot rolled steel sheet piles are commonly used in various applications, including:

1. Deep foundation pit support: Suitable for deep excavation projects such as construction and subways, resisting soil pressure and groundwater, and preventing foundation pit collapse.

2. Permanent waterfront projects: Used in port terminals, flood control dikes, and river bank protection, withstanding water impact and long-term immersion.

3. Large cofferdam construction: Such as bridge foundations and water conservancy project cofferdams, forming a sealed water retaining structure to ensure dry land operations.

4. Heavy municipal engineering: In underground pipeline corridors and integrated hub construction, it serves as long-term support and anti-seepage wall, adapting to complex loads.

5. Marine engineering: Used in shipyards and offshore facility construction, its high stiffness and corrosion resistance (optional galvanizing) adapt to marine environments.

Overall, hot rolled steel sheet piles are versatile and can be used in a wide range of applications where earth retention, water containment, and structural support are required.

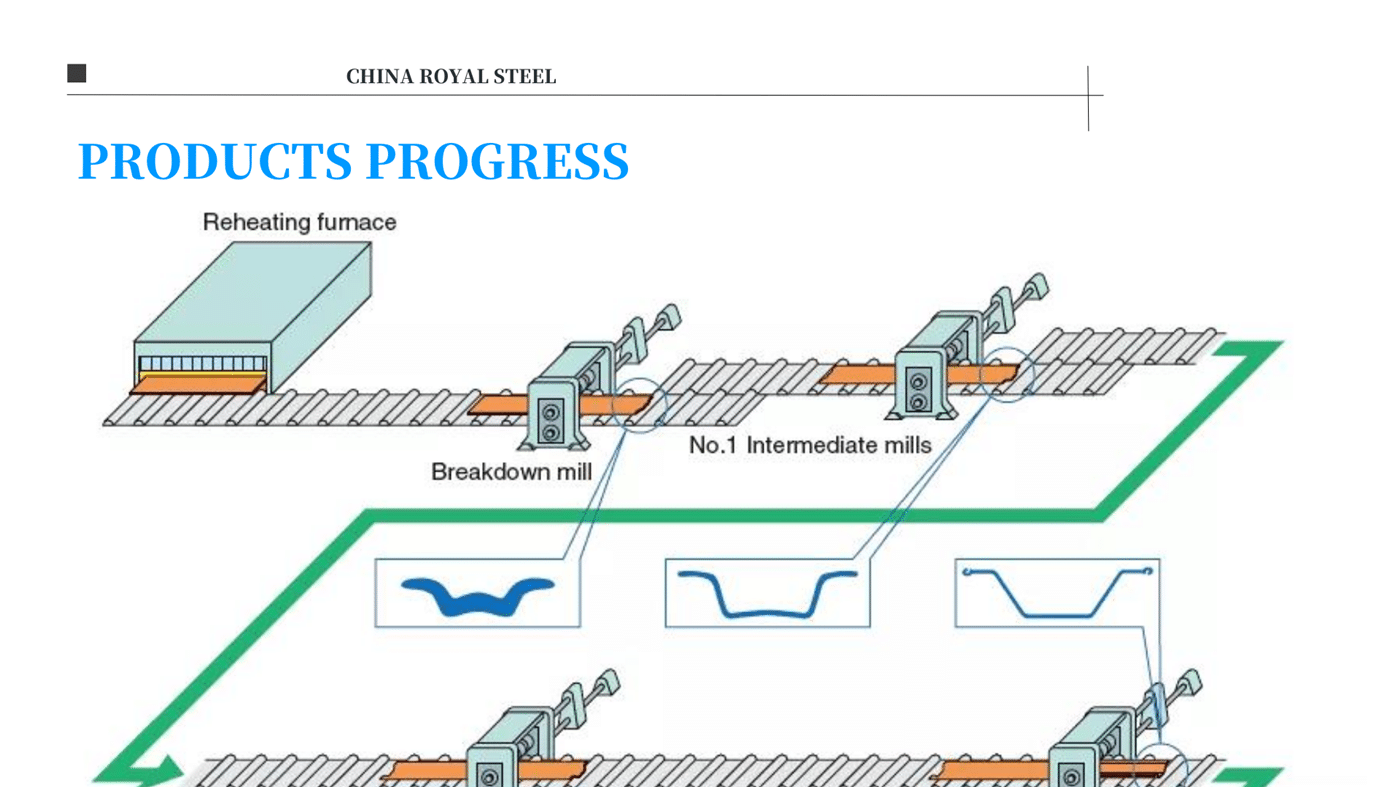

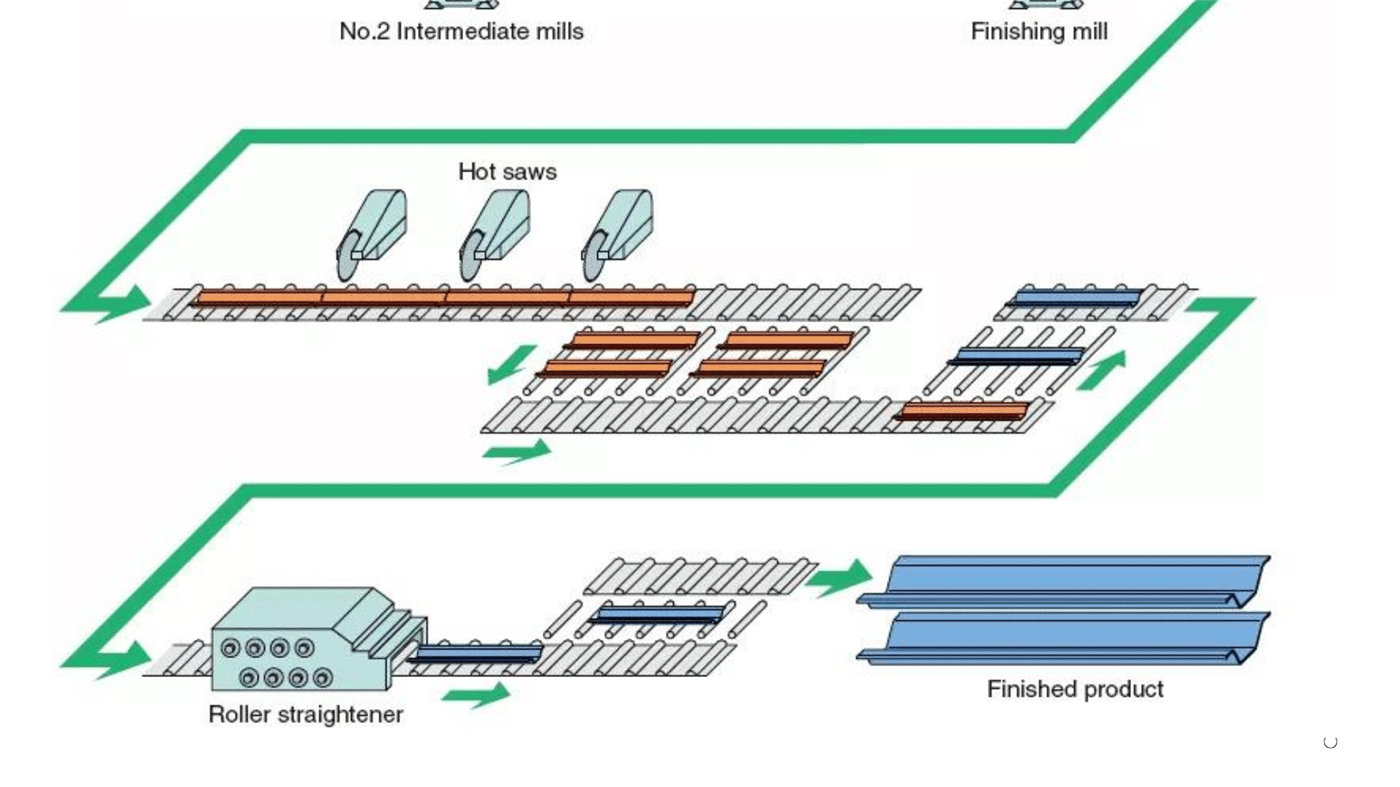

Production Process

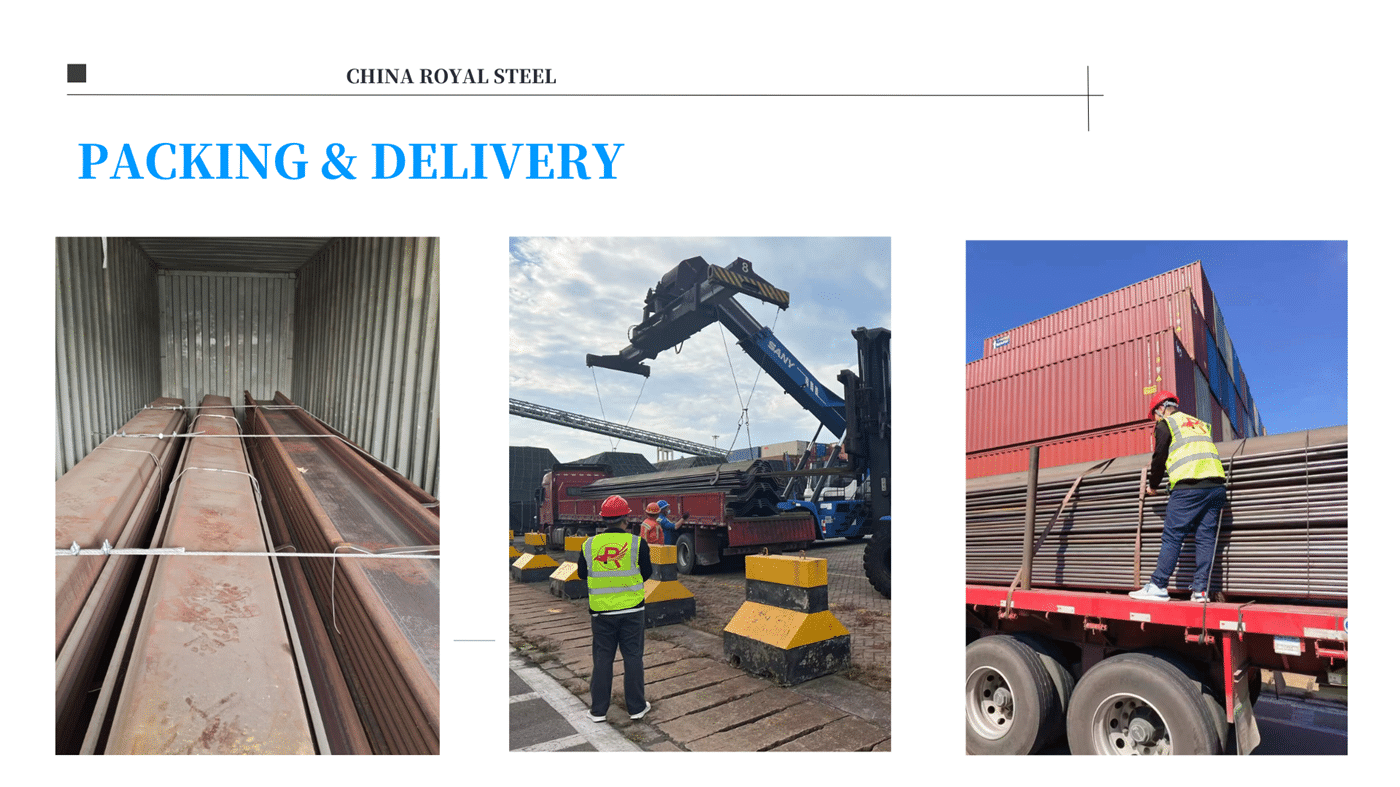

Packaging & Shipping

Packaging:

Stack the sheet piles securely: Arrange the U-shaped sheet piles in a neat and stable stack, ensuring that they are aligned properly to prevent any instability. Use strapping or banding to secure the stack and prevent shifting during transportation.

Use protective packaging materials: Wrap the stack of sheet piles with a moisture-resistant material, such as plastic or waterproof paper, to protect them from exposure to water, humidity, and other environmental elements. This will help prevent rust and corrosion.

Shipping:

Choose a suitable mode of transportation: Depending on the quantity and weight of the sheet piles, select the appropriate mode of transportation, such as flatbed trucks, containers, or ships. Consider factors like distance, time, cost, and any regulatory requirements for transportation.

Use appropriate lifting equipment: To load and unload the U-shaped steel sheet piles, use suitable lifting equipment such as cranes, forklifts, or loaders. Ensure that the equipment used has sufficient capacity to handle the weight of the sheet piles safely.

Secure the load: Properly secure the packaged stack of sheet piles on the transportation vehicle using strapping, bracing, or other suitable means to prevent shifting, sliding, or falling during transit.

Our Customer

FAQ

Q: Are u a manufacturer?

A: Yes, we are a manufacturer. We have our own factory located in Tianjin City, China.

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years gold supplier and accept trade assurance.